Aluminum Industry in Kentucky - College of Engineering

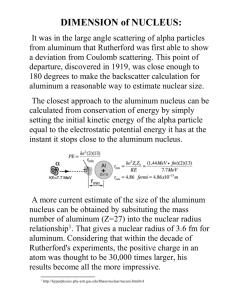

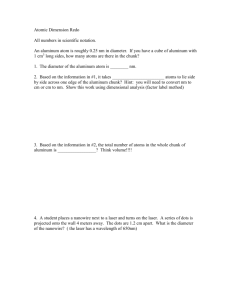

advertisement