1090299 - Extra Materials

advertisement

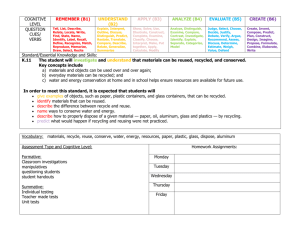

Life-cycle Analysis on Acid-gases Emissions of the Lightweight to Passenger Cars Using Aluminum Alloy and Advanced High Strength Steel Li-sa Zhu 1 1 School of Applied Science, JiLin teacher's Institute of Engineering and Technology, Changchun, China Abstract – Nowadays, in order to reduce fuel consumption and tail gas emissions, the lightweight has been adopted in passenger cars. However, whether the fuel consumption and tail gas emissions including acid-gas can be reduced must be calculated from life-cycle. In this paper, acid-gas emission of normal and modified passenger cars has been calculated in life-cycle and more detailed stages on acid-gas emission have been analyzed. Keywords –passenger cars, the lightweight, acid-gas, lifecycle I. INTRODUCTION In China, the population of passenger cars (PPC) has been increasing with drastic speed. In 1960, the PPC was only 230,000; and in 2000, the PPC has been reached 11,270,000 and almost has been increased by 50 in 40 years. Five years later, the PPC were nearly double and arrived at 20,500,000. In 2010, the PPC hit a new high and arrived at 62,040,300. It was estimated that the PPC will exceed 100 million in 2020. With the wide use of passenger cars and the tremendous PPC, much acid-gas emissions have been emitted during the using of passenger cars. Supposing that a passenger car has been drive 10,000(km/year) and drive 100 thousand kilometers before scrapping; and the amount of SO2 are 0.295(kg) in one year and 2.95(kg) before scrapping. So In 2010, the SO2 emissions by the PPC were 1802 (ton). SO2 is a main acidification gases, it can form acid rain and destroy building, forest and crops. Besides SO2, there are also a lot of acid gases in passenger cars tail gases such as NO2 and NOx. Based on mentioned above, the acidification caused by the PPC was very critical. So in order to reduce acidification gases, the lightweight to passenger cars has been adopted. The lightweight can reduce curb mass, oil consumption and acid-gases emissions of using stage, but acid-gases also have been emitted during other stages such as mineral mining, materials producing, and products manufacturing stages. So the analysis on acid-gases emissions must be considered from life-cycle, which will give the proper conclusions. II. LITERATURE REVIEW With the research progress of lightweight (LW) to passenger cars/vehicles, environmental, energy and economic issues aroused by LW have been studied. Kim Hyung-Ju et al. (2011) provided an assessment of vehicle LW with aluminum and high strength steel (HSS), and the assessment results show greater GHG savings derived from greater LW and added manufacturing costs as expected [3]. Kim Hyung-Ju et al. (2010) compared the increase in greenhouse gas (GHG) emissions associated with producing LW vehicles with the saved emissions during vehicle use, and calculated that how many years of vehicle use are required to offset the added GHG emissions from production stage, and the result show payback periods for HSS are shorter than for aluminum [4]. Kang, Yong-Lin et al. (2008) pointed out that the development and application of advanced high-strength steels (AHSS) for automobile LW not only brings about significant emissions reduction and energy-saving, but also has advances of improved safety as well as recycling and reutilization [5]. Waurzyniak and Patrick (2009) have given the result that advanced materials for automotive manufacturing are helping automakers build lighter, more fuel-efficient vehicles, and related advanced materials property, including AHSS, HSS and aluminum, has been given [6][7]. Masataka Hakamada et al. (2007) have given these conclusions that magnesium substitution can save more life cycle energy consumption than the Al substitution, although magnesium ingot production consumes more energy than aluminum and steel productions; The use of recycled magnesium ingot in a high weight ratio is needed in keeping the life cycle energy consumption and CO2 emissions low; Strength improvement in the magnesium alloy decrease total energy consumption and CO2 emissions; if the body and hood are made of magnesium alloy and the ratio of recycled ingot is sufficiently high, the total energy consumption and CO2 emissions will be markedly reduced [8]. From related articles mentioned above, the deeper studies upon LW to passenger cars/vehicles of energy and environment have been made. But acid-gas emissions were few studied. III. METHODOLOGY The proposed analysis method consist three steps: They are goal and scope definition, calculation model establishment, data collection. Particulars of each step are shown below. A. Step 1: goal and scope definition In this step, a life cycle assessment application has been used to study acidification of the lightweight to passenger cars. The scope of this step is to calculate acidification of the lightweight to passenger cars in life cycle; and scope definition is divided into five stages: 1. Mineral mining stage; 2. Materials producing stage; 3. Products manufacturing stage; 4. Transporting stage; 5. Using stage. In this paper, transporting stages only included materials transporting stage between different enterprises. So the acidification produced in internal enterprises was neglected [9]. B. Step 2: calculation model establishment In this paper, acidification calculation model has been established as below [11][12]: Acid total Acid i (1) Where Acid is acidification of the lightweight to passenger cars in life-cycle; i is from mineral stage to using stage. C. Step 3: data collection In this paper, four evaluating projects were constructed. They main parameters and acidification data are calculated by equation (1) and shown as table 5 [13- 15]. For the paper limited, only the detailed input and output data of project 1 and project2 were listed in this paper. Table II Main technologic and economic parameters of H passenger cars Model Curb mass (kg) Crew size (person) Oil consumption (L/100km) 4×2 Frontengine Frontdrive 1300. 00 5.00 13.00 Material structure Steel Iron 70 TABLE II PROJECT 1 INPUT/OUTPUT (695KG PRIMARY HIGH STRENGTE STEEL BODY) Stages in life cycle Regular Unit Mineral mining Input Output Iron ore Scrap Manganese Limestone Dolomite Fluorite Iron mud Water Diesel fuel Gasoline kg kg kg kg kg kg kg kg kg kg Nature gas CO2 CO SO2 NOx CxHy HC Dust H2S m3 kg kg kg kg kg kg kg kg N2O kg 241 9.4 1.87 615.07 301.21 41.08 19.63 13.85 198.76 Materials producing 16503 196 113 384 666 5 219 281625.58 4.27 3958.65 35.08 35.08 3369.68 499.20 11.30 266.24 1.10 Product manufacturing Transporting 123956.15 7 8.20 0.94 76.71 454 0.02 0.02 2.47 0.04 263 1829.98 0.15 0.15 30.32 0.08 Using 21497.16 68835.4 5011.06 5011.06 625.64 987.39 9.77 TABLE III PROJECT 2 INPUT/OUTPUT (375.3KG PRIMARY ALUMINUM BODY) Stages in life cycle Unit Mineral mining Input Bauxite Soda ash Limestone Anthracite Baking soda Bay red mud kg kg kg kg kg kg Materials producing 6831 195 891 128.50 41 2680.88 Product manufacturing Transporting Using 30 Stages in life cycle Unit Mineral mining kg kg kg kg kg kg kg kg kg kg kg kg kg m3 KW.H kg kg kg kg kg kg 74.22 53.5 896.80 75 561.69 201.25 20027.81 434.48 95.09 0.12 0.12 0.48 0.01 5923.66 490.12 108.78 54.06 0.22 407.56 0.02 0.48 2.21 0.06 HC kg 0.02 PM kg 0.02 HF kg 17.30 Dust kg 42 Table V ACIDIFICATION(SO2.EQ KG) DATA of EVALUATING PROJECTS* MM MP PM T U Total Project 1 54.82 2417.94 24.57 2.27 446.70 2946.30 Project 2 0.46 146.62 2.03 1.72 348.64 499.70 Project 3 5.98 2.03 0.42 348.64 357.07 Project 4 42.41 129.19 1.01 405.64 988.25 *MM is mineral mining stage; MP is materials producing stage; PM is product manufacturing stage; T is transporting stage; U is using stage. In table.2, project 1 is basic passenger car, which body in white (BIW) was made by high strength steel (HSS) and curb mass is 1300.00 (kg). Project 2, 3, 4 are modified passenger cars, whose BIW were replaced with primary aluminum alloy, recycled aluminum alloy and advanced high strength steel and curb mass were 980.3(kg), 980.3(kg) and 1166.40(kg) respectively. Oil consumption of using stage is calculated by equation (2). Gasoline M (L/100km) (2) Where 8.072 ; 1.019 . Product manufacturing Transporting Using 344.72 0.015 0.41 1.87 0.03 16775.74 53717.07 3910.48 6.88 488.23 770.53 6.33 Total Using Projects Output Carbon pole Cryolite Aluminum fluoride Calcium fluoride Magnesium fluoride Nacl KCl Water Diesel fuel Anthracite Datong system of coal Matellurgical coke Heavy oil Nature gas Electricity Gasoline CO2 CO SO2 NOx CxHy Materials producing 759 22.10 35 4.10 5.50 27 27 41068 Transporting Production manufacturing Materials producing Mineral mining 0 500 1000 1500 2000 2500 3000 3500 Acid-gass emissions(SO2.eq) Project 1 Project 2 Project 3 Project 4 Fig.1 Acid-gas emissions of projects IV. DISCUSSIONS: EFFECTS OF DIFFERENT MATERIALS AND USING DISTANCE This part included three contents: Effects of primary aluminum; Effects of recycled aluminum; Effects of advanced high strength steel (AHHS). A. Effects of primary aluminum Compared with normal project1, project2'BIW were replaced with primary aluminum and its life-cycle acidgases emissions were reduced from 2946.30(SO2.eq kg) to 499.70(SO2.eq kg). That mainly because that acid-gases emissions of project2 were extremely reduced in materials producing stage. Concrete details were shown as fig.2. amount of acid-gases emission is higher in using stage; 3000 450 400 2500 350 2000 300 acid-gases amonut 1500 250 1000 200 500 150 100 0 MM MP PM T U Total 50 Life-cycle Stages 0 Project 1 Project 2 Project 1 Project 2 Project 3 Project 4 PM 24.57 2.03 2.03 129.19 U 446.7 348.64 348.64 405.64 Fig.2 Acid-gases amount between project1 and project2 B. Effects of recycled aluminum Compared to primary aluminum, at materials producing stage, recycled aluminum can extremely reduce acidgases emissions. But recycled aluminum has less effect on total acid-gases emissions in life-cycle of passenger cars. That mainly because the acid-gases emissions of using stage dominates the life-cycle acid-gases emissions. As in developed countries, the ratio of recycled aluminum has surpassed 50%. So in this paper, six recycled ratio of aluminum have been considered, they were 50%, 60%, 70%, 80%, 90%, 100% and details data were shown as Fig.3. Fig.4 The amount of acid-gases in product manufacturing and using stages of all projects and the amount of acid-gases emissions in product manufacturing is the highest in all projects. The specific results were shown as Fig.4. D. Effects of USING DISTANCE As to the most acid-gases emissions are emitted during using stage, it is essential to consider the effects of using distance. In this paper, the using distance is 200,000(km), and the sensitivity analysis of per 10,000 (km) must be calculated. 3500 700 3000 600 2500 500 2000 400 1500 300 1000 200 500 100 80 SO2.eq kg 70 60 50 40 0 10 15 20 1E+4km 20 Project 1 Project 2 Project 3 Project 4 Fig.5 Sensitivity analysis of Acid-gases emissions 10 0 0 5 30 50% 60% 70% 80% 90% 100% 76.3 62.24 48.17 34.11 20.04 5.98 Fig.3 Effects on acid-gases emissions of recycled aluminum ratio From Fig.3 that if the ratio of recycled aluminum can be reached 70%, the amount of acid-gases emissions in materials producing stage can be reduced 98.45(SO2.eq kg) and if the ratio is reached 100%, in materials producing, amount of acid-gases also can be arrived at “zero”. C. Effects of AHHS From table.5, due to adopted AHHS, the amount of acidgases on project2 was second in all projects. That mainly due to the density of AHHS is higher than neither primary aluminum nor recycled aluminum alloy, which led to the From Fig.5, the sensitivity analysis results are as same as the life-cycle, that only because compared to using stage, the acid-gases emissions, in mineral mining, materials producing, product manufacturing and transporting stage, are very few. V. CONCLUSIONS From these studies, main conclusions have been achieved from life cycle as follows: 1. The acidification emissions of project 1 is the most in all projects, that means basic passenger cars emit acidgas amount is bigger than modified passenger cars. That mainly due to basic passenger cars emitted more acid-gas in materials producing stages and should be given ample attention; 2. Applying recycled aluminum alloy can extremely reduce acid-gas emissions than primary aluminum alloy. That mainly due to acid-gas emissions can be reduced in materials producing stages by using recycled aluminum alloy. So in order to reduce acid-gas emissions, the ratio of recycled aluminum alloy must be height. Nowadays, the ratio of recycled aluminum alloy has been arrived at 50% to 60% in developed countries, and the ratio is very poor in developing countries. So the potential of improving recycled ratio of aluminum is very tremendous in the word. If the conditions are permitted, the mechanism of recovering scrap aluminum should be built. 3. The acid-gas emissions of using AHHS is higher than using neither primary or recycled aluminum alloy, and that due to acid-gas emissions is higher in production manufacturing and using stages. Detailed results and conclusions have been shown as Figure 1. VI. ACKNOWLEDGEMENT This paper was supported by the outline of the eleventh five-year scientific and technological plan of Jilin province education department [No.2009 (279)]. VII. APPENDIX A. Ingredient of tail gas Table VI Main ingredient of tail gas (g/L) Ingredient Weight CO2 2321.5 SO2 0.295 CO 169.0 NOx 21.1 33.3 CxHy B. Acidification potential Ingredient SO2 SO3 NO2 NOx NO HNO3 NH3 HF H2S HCl H2SO3 H3PO4 Weight 1 0.8 0.7 0.7 1.07 0.51 1.88 1.6 1.88 0.88 0.65 0.98 REFERENCES [1] TONGXiao-Guang, Zhao Lin, and Wang Ru-Lang, “Thinking on oil reserves of China (Periodical style),” Research on Economics and management. CHN., Apr. 2009. [2] Importing vehicles market, “Vehicles lightweight road journey of audi company (EB/OL),” CHN., Sep. 2009. [3] Kim hyung-Ju, Keoleian Gregory A, Skerlos Steven j, “Economic assessment of greenhouse gas emissions reduction by vehicle lightweight using aluminum and highstrength steel (Periodical style),” Journal of industrial ecology. ENG., PP:64-80, Vol,15(1), 2011. [4] Kim hyung-Ju, McMillan Collin, Keoleian Gregory A, Skerlos Steven J, “Greenhouse emissions payback for lightweight vehicles using aluminum and high-strength steel (Periodical style),” Journal of industrial ecology. ENG., PP:929-946, Vol.,14(1), 2010. [5] Kang Yong-Lin, “Lightweight vehicle, advanced high strength steel and energy-saving and emission reduction (Periodical style),” Kang Tieh/Iron and Steel. ENG., Vol.,14(1),2008. [6] Waurzyniak, Patrick, “Advanced materials in automotive: Newer steels, aluminum, magnesium, and other materials lead to more lightweight, economical vehicles (Periodical style),” Manufacturing engineering. ENG., Vol.,143(3), 2009. [7] Li an, Chao Zan-Yi, “Advanced materials in automotive: Newer steels, aluminum, magnesium, and other materials lead to more lightweight, economical vehicles (Periodical style),” Manufacturing engineering. ENG., Vol.,143(3), 2009. [8] Masataka Hakamada, Tesuharu Furuta, “Life cycle inventory study on magnesium alloy substitution in vehicles (Periodical style),” Energy. ENG., pp:1352-1360, 2007. [9] JianXu, XiaomingBu, FengLiZheng, “Manufacturing industry green product appraisal system based on product life cycle (Published Conference Proceedings style),” in Proc. The sixth wuhan international conference on Ebusiness-innovation management, pp.3258–3261, 2008. [10] Tonn B.E, Schexnayder S.M Peretz J.H, Das S, “An assessment of waste issues associated with the production of new, lightweight, fuel-efficient vehicles (Periodical style),” Journal of cleaner production. ENG., pp:753-765, Vol.,11(7), 2009. [11] Pingtao Yan, Mengchu Zhou, Donald Seatian, “Multi-lfie cycle product and process development: selection of optimal production, usage, and recovery process (Published Conference Proceedings style),” in Proc. Proceeding of the 1999 IEEE international symposium on electronics and the environment, pp.274–279, 1999. [12] G.A.Kekoleian, “The application of life cycle assessment to desigh (Periodical style),” Clean production. ENG., pp:143150, Vol.(1), 1993. [13] Liu Hai-Dong, Liu Guo-Liang, “Research on the forecasting equation shower of the fuel saving rate of passenger cars (Periodical style),” Journal of Beijing institute of technology (english edition). ENG., pp:171-174, Vol.17, 2008. [14] Liu Hai-Dong, Liu Guo-Liang, “On the theoretical limit of the lightweight of passenger cars based on the core of industrial engineering on eliminating clean in effective work (Published Conference Proceedings style),” in Proc. 2008 international conference on management science and engineering 15th annual conference proceeding, ICMSEt, pp.357–361, Vol.(1), 2008. [15] Liu Hai-Dong, “Research on evaluating green-effect theories and methods of the lightweight to passenger cars (Thesis or Dissertation style),” Ph.D. dissertation, Management science. CHN. , Jilin Univ., 2011.