Auto Electronics Industry Analysis and Investment Opportunities

advertisement

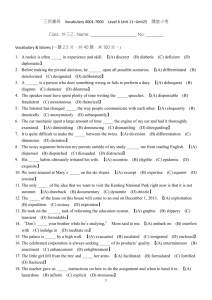

Auto Electronics Industry Analysis and Investment Opportunities Department of Investment Services, MOEA July 2009 1 Table of Contents I. Trends in the Global Auto Electronics Industry……………………............3 1. Survey of the Global New Automobile Market………………………............4 2. Auto Electronics Development Trends………………………………............4 3. Status II. Status of the Global Auto Electronics Market………………...........7 of Taiwan’s Auto Electronics Industry ………….............10 1. Supply and Demand of the Auto Electronics Industry………………...........10 2. Gaps in Industry Supply Chain, Investment Niches, and Prospective Foreign Investors……………………………………………………............11 3. Major Suppliers in Taiwan………………………………………….............13 III. Investment Opportunities for Foreign Investors….............………………16 IV. Investment Incentives…………………………............……………………19 V. Industry-Academia Collaboration in Taiwan………............……………23 2 Under the impact of the 2008 global financial crisis, the largest automobile manufacturer in the United States, General Motors, declared bankruptcy and Chrysler entered a phase of bankruptcy negotiations with the U.S. government. The amount of U.S. government financial support for the automobile industry continues to climb and Japan’s Toyota Motor Corporation has posted a loss for the first time in 46 years. In such an arduous operating environment, the pace of global automotive industry R&D continues unabated, especially efforts to introduce more and more auto electronics to boost the energy efficiency of vehicle operation and use IT technology to achieve seamlessly connected vehicles. Thus, auto electronics is a key tool for weathering the global economic crisis. Taiwan’s IT industry has accumulated considerable strenght and many of its hardware products are unmatched for production value. Furthermore, it has engaged in creating new value for the consumer and in upgrading via its complete IT industry supply chain. Effective integration of auto electronics development trends will be a key advantage for the development of Taiwan’s auto electronics industry. I. Trends in the Global Auto Electronics Industry Auto electronics are system products involving automobile manufacturing, electronics, optoelectronics, and IT technologies. Key components include sensors, micro-controllers, microprocessors, driver devices, telecom components, power supply devices, passive electronic components, and indicators. Applications include engine/power-train systems, suspension/chassis systems, safety systems, car body electrical systems, driver information systems, and security systems. To satisfy new demands for saving energy, safety, comfort, and even intelligent functions, the proportion of electronic products carried in automobiles has grown over the years. By 2012, auto electronics will account for 40% of the total price of an automobile, a dramatic increase of 26% over 2003, so the market potential is obvious. 3 1. Survey of the Global New Automobile Market The worldwide new automobile market sustained an unprecedented blow as a result of the global financial crisis that hit during the second half of 2008, and new-car sales for September 2008, which posted a new 15-year low. The sales volume of Toyota automobiles fell 32%, the largest single-month drop in 40 years. Global output for all of 2008 was 58 million vehicles; the figure will drop to an estimated 56.4 million in 2009, and is forecast to recover to the 60 million mark by 2012. Chart 1. New Automobile Output Volume Worldwide Unit: 1 million vehicles 61 60.6 單 位 60 : 百 59 萬 輛 58 57 59.5 58 57.8 57.4 56.7 56.4 56 55 54 2006 2007 2008 2009(e) 2010(f) 2011(f) 2012(f) Source: Wards Automotive (May 2009) 2. Auto Electronics Development Trends In the development of automotive components before the 1970s, the key area of technical development was, for the most part, mechanical structure components. The structural design technology developed during this period became the key foundation for the subsequent development of auto electronics. Afterwards, in line with the trend toward the increased use of electronics in automobiles, automotive technology continued to build on the foundation of traditional mechanical structures; with the 4 maturity of design techniques for the internal combustion engine, chassis, and body frame, electrical technologies based on motors were developed to improve the heat dissipation of internal combustion engines and enhance the (DC generator) electrical generating equipment of the vehicle and the electrical engine starter. With the rapid development of semiconductors in the 1980s, automotive technology continued to introduce large-scale applications of diode, transistor, and silicon chip technologies, leading to the dawning of the age of auto electronics. This stage also saw the initial development of fuel injection controllers, electronic climate control, and electrical controller technology for automotive receivers and stereo systems. With the rapid development of electronic control technology, as well as semiconductor and integrated circuit development, the microcontroller chips used in automotive electronic control unit (ECU) of the time developed from 4-bits, to today’s 32-bit or even 64-bit versions. Continuous upgrades of processing speed and controll capabilities allowed attainment of highly intelligent auto electronic controllers. However, large amounts of electronic product applications and the need for information from the electronic controller units of each automotive system to flow via individual cables, and for interfacing with other electronic controller units via point-to-point interfaces, made vehicular wiring distribution important Iincreasingly complex cabling added to the difficulty of inspection and maintenance , and resulted in greater length and weight of wiring, which pushed up costs. Accordingly, vehicle interior digital controller networking technology was developed in the 1990s, such as CAN, LIN, FlexRay and MOST, with ring net concepts being applied to vehicle interior electronic control networks that allowed the electronic controller units in the system to send and receive information via an LAN bus and attaining multi-node communication capability. This also overcame the shortcomings caused by traditional cabling. In addition, in the power generation and transmission part of the vehicle, environmental power generation technologies, including hybrid power generation, electrical power generation, hydrogen energy, and bio-material 5 generation have become the developmental norm and electronic technology has gradually shifted from its supporting role of the past to become the core technology of automotive development. Chart 2. Developmental Timeline of Global Auto Electronics Clean, efficient power source technology (hydrogen, hybrid, electrical) Digital Network Control Technology (CAN, LIN, MOST, X by Wire) Electronic control technology (power train control, climate control, chassis suspension control) Technical development of electrical control components (transistors, diodes and embedded processors) Electromechanical power technology (generators, starter motors, power cooling system and automotive lighting Technological Development Basic automotive technology (power train, chassis, car frame) ~1970 High-efficiency engines Power Train Chassis 1980 Engine management systems Manual speed shifter systems Chassis mechanical frame 1990 2000~ Electronic fuel-injected engines Electronic fuel-injected engines Hydraulic assisted brake system Electronic manual transmissions Hydrogen propulsion Automatic transmission systems Hydraulic assisted steering systems Traction control systems X-by-wire Hydraulic independent suspension systems Anti-lockup breaking systems (ABS) Dynamic stabilization systems Car Body Vehicle driving illumination system Security Safety Electric window controls Climate control systems Car door centralized control system Car alert systems Supplemental safety airbags Driver Information Mechanical display Product Development LED lighting FM radio HID headlights Keyless entry systems Tire pressure monitoring system Electrical display Hybrid propulsion Adaptive front lighting systems Passive sensor entry system Engine lock chip Navigation systems Car Infotainment systems Car Stereo LED headlights Anti-collision warning system Digital display Car equipped IT systems Head-up display Digital broadcasting 6 Major automobile manufacturers the world over display their concept cars of the future at major automotive exhibitions every year, and the ideas they roll out always exceed what is imagined. An opinion survey of industry, government, and academic specialists reveals a high degree of automotive society development in the 21st century. The survey indicates that the future development of the automobile will center on environment, energy, social system, and safety, and all of these areas require a combination of electronic control technology, new materials, and biotechnology. Chart 3. Future Trends for Intelligent Vehicles Source: “21st Century High Degree Automotive Society” Cross-industry Data Survey Association, Japan 3. Status of the Global Auto Electronics Market As the ratio of auto electronics devices in each automobile increases each year, so does market demand for auto electronics. According to statistics, the global market size for electronic systems in automobiles (systems with electronic components, including some mechanical parts) reached US$158.2 billion in 2008, for a gain of 6.3% over 2007. With the impact of the global financial crisis, the worldwide auto electronics market is expected to contract 14.8% in 2009 but return to a scale of 7 US$176 billion by 2012, with a compound average annual growth of 2.7% between 2008 and 2012. Table 1. Market Size of Global Auto Electronics Systems Applications by Sector Unit: US$1 million CAGR 2008 2009(e) 2010(f) 2011(f) 2012(f) 2008–2012 Power Train Chassis 53,175 45,199 47,459 51,255 60,481 3.3% 18,419 14,735 15,030 16,984 18,682 0.4% Safety 24,540 22,086 22,528 24,330 26,763 2.2% Security 3,426 2,741 3,152 3,467 4,161 5.0% Car Body Driver Information 37,499 32,999 33,329 36,995 40,695 2.1% 21,165 20,107 20,509 22,560 25,267 4.5% Total Growth Rate 158,224 137,867 142,006 155,591 176,049 2.7% 6.3% -14.8% 2.9% 8.7% 11.6% - Source: Compiled for this report. Categorized by the area in which auto electronics are installed, in 2008 the power train market segment was the largest of the six areas, accounting for 33%, followed by car body at 24% and safety at 16% (as indicated in Chart 3). The primary reason for the power train area having the largest market segment is a response to vehicle emissions standards and continuing rise in oil prices, which have stimulated R&D into energy-conserving engines. Also, as auto manufacturers around the world continue to devote more of their production lines to hybrid or diesel automobiles, the power train’s 33% market share of total auto electronics in 2008 will continue climbing and reach 35% by 2012. 8 Chart 4. Auto Electronics Market Share by Application Area 2008 Auto Electronics Market Share by Application Area 2008年各汽車電子應用領域比重 2012 Auto Electronics Market Share by Application Area 2012年各汽車電子應用領域比重 Driver駕駛資訊 Information 13% 13% Driver Information 駕駛資訊 14% 14% Power Train 動力傳動 33% 33% Power Train 動力傳動 35% 35% Car Body車身 24% 24% Security保全 2% 2% Car車身 Body 23% 23% 安全 Safety 16% 10% 底盤 Chassis 12% 12% 保全 Security 2% 2% 安全 Safety 15%15% 底盤 Chassis 11%11% Source: Compiled for this report. Among these six application areas, another market into which manufacturers are pouring R&D effort is safety. In addition to the safety needs of human beings, the principal reason for this effort lies in the R&D advances made by automobile system manufacturers in active auto safety technologies such as advanced supplemental safety airbags, pedestrian protection systems, blind-spot warning systems, car lane departure warning, and night vision systems. However, advanced safety equipment is often first adopted in high-end vehicle models; it is optional in mid-range models, and awaits utilization in high-end models and a fall in costs before it evolves into a standard feature. Taiwan currently has many IT/telecomm electronic manufacturers working to position themselves in the driver information system market, which is projected to grow from US$21.17 billion in 2008 to US$25.27 billion in 2012 for a compound average annual growth rate of 4.5%. II. Status of Taiwan’s Auto Electronics Industry 9 Although the domestic demand market for automobiles in Taiwan is small and its electronics industry lacks global Tier 1 manufacturers, the R&D capacity amassed by it’s the island’s electronics industries, its complete industry chain, and the flexibility and capacity demonstrated by its Tier 2 or component manufacturers make those industries ideal suppliers and collaborative partners for global Tier 1 manufacturers. And as the automobile market on the Chinese mainland comes into its own, Taiwan manufacturers can exploit the advantages of geographic proximity and cultural and ethnic affinity to actively position themselves in the Chinese electronics market with great effectiveness, providing an important niche for Taiwan’s auto electronics industry. 2.1 Supply and Demand in the Auto Electronics Industry Auto electronics appear in a wide range of automotive applications, with nearly 100 categories of system products from power train, chassis, and car body to driver information and multimedia entertainment. With the capabilities amassed by Taiwan’s IT/telecom industry, together with the R&D conducted by Taiwan’s automotive industry on its own initiative and it industrial system, an important industrial development strategy is to screen the core competitiveness and R&D capabilities of domestic manufacturers and select products that have development potential and are suitable for Taiwan. Since Taiwan’s whole-car technology is closely tied in with the foreign technology of the parent manufacturers, and the development of Taiwan’s auto parts industry is primarily based on that are not directly related to safety, products most areas in which Taiwan auto electronics firms are pouring their resources begin with car body electronics, driver information, and security products, then gradually extend to electronic products pertaining to core automotive engine/power train and suspension/chassis control systems. Taiwan’s auto electronics products that currently have development potential include supplemental air bags and tire pressure sensors in the safety area; car alert systems, 10 keyless entry systems, passive sensor entry systems, and engine lock chips in the security area; car illumination systems (including HID headlights, adaptive front lighting, and LED lighting) in the car body area; and navigation systems and car infotainment systems in the driver information area. A depiction of product distribution throughout the vehicle is provided in Chart 5. Chart 5. Taiwan’s Auto Electronics Products with Development Potential Source: Compiled for this report. 2.2 Gaps in Industry Supply Chain, Investment Niches, and Prospective Foreign Investors Taiwan currently has auto electronics manufacturers active in each of the six major areas of the auto electronics industry. In the safety area, the Mei-An Autoliv Co., a subsidiary of the Swedish safety air bag maker Autoliv, is developing supplemental safety air bag products. Domestic manufacturers developing tire pressure sensor systems and vehicle backup radar products are primarily selling in the after-sales market. Taiwan’s strong, CMOS and CCD lens electronic technology provides plenty of room for developing vehicle backup radar. 11 In the security area, DunYoung Co., Whetron Electronics Co., and Tung Thih Electronic Co.,., which has long engaged in technological cooperation with Japan’s Mitsui, have a solid share of the car alert system, keyless entry system, and passive sensor entry system markets and have become Tier 1 suppliers to the original parts market. In the car body area, products developed in Taiwan at present include car window controls, climate controls, x-by-wire components, and auto illumination systems. For example, Tung Thih Electronic Co. and Whetron Electronics Co. have become Tier 1 suppliers of car window controller components, and the Japanese-owned Ta Yih Industrial Co. has become a Tier 1 car illumination product supplier. Elitech Technology Co. provides the Ta Yih Industrial Co. with modular components, becoming a Tier 2 supplier. Taiwan Calsonic, Taiwan General Exporters, and Japanese subsidiaries Denso Taiwan and Matsushita Taiwan are Tier 1 manufacturers of climate control systems. Manufacturers developing x-by-wire products include the Antec Electric System Co., Rica Auto Parts Co., and Taiwan Yazaki Corp. In the driver information area, manufacturers developing car infotainment products, such as Clarion and Taiwan Matsushita, remain subsidiaries of parent Japanese companies which control their technology. However, the Universal Scientific Industrial Co., E-Lead Electronic, BenQ, and Hamg Shing Technology Corp. serve as Tier 1 suppliers of mobile information systems, while Chao Long Motor Parts Co. and Lien Cheng Co. have become Tier 1 suppliers of dashboard parts used by auto manufacturers in their products. Taiwan used to lack its own technology for core automobile systems. Few electronic control systems for the propulsion, engine, power train, suspension, and safety areas have been developed, but Taiwan has many OEM manufacturers of Tier 1 system modules and has amassed a certain technological prowess. In addition, Taiwan’s capabilityies in propulsion motor technology are quite complete. Thus, bringing in Tier 1 manufacturers with integrated core system technology such as Denso, Visteon, Delphi, and Johnson Controls, to work with Taiwan’s complete mechanical, electrical, 12 and electronic industry chain, in combination with the enormous demand for automobiles on the Chinese mainland, would create new market opportunities. The innovation, R&D, and manufacturing prowess of Taiwan’s IT/telecom industry is unparalleled. Foreign firms could use various methods to cooperate with Taiwan’s IT/telecom manufacturers in the field of car navigation and infotainment, to upgrade the value-added of such systems and create cost advantages for a win-win solution. 2.3 Major Suppliers in Taiwan Table 2. Current Status of Taiwan Auto Electronics Suppliers by Sector Auto Electronics Sector Auto Electronics Product Manufacturers Involved Engine compartment management Universal Scientific Industrial Co.; Shihlin Electric Co. Starter motor, generator Shihlin Electric Co. Cruise control DunYoung Co. Propulsion/Power Train Chassis Anti-locking brake systems Bosch Taiwan Supplemental air bag Universal Scientific Industrial Co.; Mei-An Autoliv Co. Tire pressure sensor systems Universal Scientific Industrial Co.; Mobiletron Electronics Co. Safety belts Mei-An Autoliv Co. Car backup radar Tung Thih Electronic; Safety Antec Electric System Co. Car backup system CMOS DunYoung Co. Car backup system CCD Hamg Shing Technology Corp.; E-Lead Electronic,; Whetron Electronics Co. Car anti-theft alarm Tung Thih Electronic; Whetron Electronics Co.; DunYoung Co. 13 Keyless entry systems Whetron Electronics Co. Door control Tungthih Electronic; Whetron Electronics Co. Windshield wiper control Whetron Electronics Co.; Denso Taiwan; Shihlin Electric Co. Car illumination systems Ta Yih Industrial Co.; Depo; China Fastener Co. Electric window control DunYoung Co.; Taigene Electric Machinery Co., Ltd. LED tail lights DunYoung Co.; Universal Scientific Industrial Co.; Everlight Electronic Co.; LiteOn Technology Corp. Car Body Driver Information Climate control systems Taiwan Calsonic; Taiwan General Exporters.; Taigene Electric Machinery Co.; Taiwan Denso; Taiwan Matsushita Electric seat adjusters Taigene Electric Machinery Co.; Antec Electric System Co. Automotive x-by-wire Antec Electric System Co.; TaiYue Electric Co..; Taiwan Yazaki Corp. Car infotainment systems Clarion Taiwan; Matsushita Taiwan; PROTON; E-Lead Electronic; Clientron Corp. Onboard IT system Universal Scientific Industrial Co.; E-Lead Electronic; BenQ; Hamg Shing Technology Corp.; Mobiletron Automobile picture screens Clarion Taiwan; Matsushita Taiwan; PROTON; Antec Electric System Co..; Universal Scientific 14 Industrial Co.; Hamg Shing Technology Corp. Car navigation systems Universal Scientific Industrial Co.; E-Lead Electronic; BenQ; Hamg Shing Technology Corp.; MITAC; Garmin Corp. Digital television Antec Electric System Co.; Mobiletron; E-Lead Electronic Dash board panels Chao Long Motor Parts Co.; Lien Cheng Co. Rear-view mirror picture screen Fitness Factory; Mobiletron; Tung Thih Electronic LCD panel AUO; Chimei; InnoLux; TPO Displays Corp. Source: Compiled for this report. 15 III. Investment Opportunities for Foreign Investors The automotive industry is the locomotive of a country. The scope of its related industries is closely tied to electronics, mechanics, steel, plastics, and glass. A hundred satellite plants support a car plant producing finished vehicles. An employee at a plant producing finished vehicles can create over three other job opportunities, and thus auto manufacturing becomes a key industry to be protected in each country. At the outset of Taiwan’s auto industry development,, Japanese parent plants controlled the technology. With no technology of its own as backup, and with the effects of a lack of favorable factors, development was constrained. But government support in the form of a first- and second-stage automotive industry development strategy boosted the rate of domestic production and brought automotive component development and manufacturing capabilities. Taiwan automotive component manufacturers not only possess manufacturing capability, but also are capable of creating new designs for components. Looking at the overall structure of Taiwan’s automotive component industry, there are 2,343 plants connected with the manufacture of auto parts in Taiwan and approximately 85,000 people employed in the industry. Over 90% of these parts makers are small and medium-sized enterprises (SMEs). Despite most manufacturers in the industry being SMEs, their parts have gradually gained a dominant share of the overseas sales and service market. The revenue generated by each worker in the automotive parts industry has steadily risen over the years, breaking through the NT$4.86 million mark in 2007. Viewed in terms of technological capability indicators, the amount of money spent purchasing technology gradually declined, from NT$5.51 billion in 2003 to NT$4.07 billion in 2007, while, the amount of technology sales rose from NT$340 million in 2003 to NT$580 million over the same period. This reflects a gradual rise in the in-house technological capabilities of Taiwan manufacturers. 16 Table. 3 Revenue Performance and R&D Expenditures of Taiwan’s Automotive Parts Manufacturers 2003 2005 2007 Number of Manufacturers 2,033 2,322 2,343 Employees (1000) 76 88 85 Operating Revenue (NT$ million) 4,037 5.080 4,119 Technology Purchases (NT$ million) 55.1 46.9 40.7 Technology Sales (NT$ million) 3.4 4.3 5.8 Source: Industry Statistics Survey (May 2009), Ministry of Economic Affairs In terms of size, with the exception of University Scientific Instruments Co., E-Lead Electronics, Mobiletron, Ta Yih Industrial Co., and China Fastener, which are large over-the-counter traded companies with 500 or more employees each, Taiwan’s auto electronics manufacturers are mostly SMEs. When Taiwan auto electronics manufacturers that have begun to engage in R&D on advanced automobile control and safety products are compared with major international manufacturers, they still lag behind in of number of employees and revenue generated. Given the limited size of the domestic market, cooperation with large international manufacturers is the best strategy for Taiwan’s auto electronics manufacturers. With Taiwan’s accession to the WTO and the trend toward globalization, the development of the island’s automobile industry has entered a period of intense competition. Gaining core advantages and global competitiveness has become a major developmental strategy for manufacturers. Especially given the impact on the industry of the shift to auto electronics and intelligent vehicular systems, Taiwan’s manufacturers need to overcome an enormous gap. One after another, domestic manufacturers such as Universal Scientific Industrial Co., Mei-An Autoliv Co., DunYoung Co., Whetron Electronics Co., Mobiletron, and Tung Thih Electronic Co. are engaging in R&D on advanced auto electronics technology. In addition, in line with the R&D direction taken by Taiwan’s manufacturers domestically, domestic automotive research institutions are also actively engaged in forward-looking technological R&D or are collaborating with manufacturers to develop new products. 17 For instance, the Chung-Shan Institute of Science and Technology, in addition to cooperating with Tsuang Hine Steering Wheel Co., Ltd. to develop air bags and safety belts, is currently actively engaged in R&D pertaining to airbag ECUs, tire pressure sensors, night vision systems, anti-collision radar systems, and the like. The Industrial Technology Research Institute’s Mechanical and Systems Research Laboratories are working with the China Motor Corp. to develop a vehicle-mounted lane departure warning system. Summary The auto electronics industry has been developing over more than three decades; but with the conceptual derivations of active safety, energy conservation, and environmental friendliness, as well as advanced intelligent control, innovative technology products in many categories continue to emerge. With the exception of navigation systems, rear seat entertainment systems, tire pressure sensor systems, and advanced safety airbag and parking assistance systems, most car body electronics and driver information systems are still in the initial phase of their life cycles, with pertinent R&D and products continually being announced and introduced. The technological development of tire pressure sensors and head-up displays in Taiwan has already entered the mass-technological improvement, with some manufacturers entering the production phase, leaving a relatively small technological gap between them and large international manufacturers. In line with the driving force of demand in the international market, if the reduction on production costs can be accelerated, as global purchasing of automotive components speeds up, Taiwan will be presented with outstanding opportunities in the international market. In the areas of navigation and entertainment systems, where Taiwan has extremely strong advantages, in addition to the original equipment market it has a certain share of the after-sales market as well, with a 46% share of the European entertainment and navigation system aftermarket, amounting to nearly €1.7 billion. Taiwan currently continues to upgrade its ability to negotiate pricing with international automakers and, in case after case, is gaining a foothold in the original equipment markets of newly 18 emerging countries, with great opportunities for future market growth. In addition, domestic manufacturers possess the competitive strengths of assured product quality and flexible manufacturing. Utilizing core technology and achieving the ultimate goal of securing footholds in the markets of advanced areas such as the EU, US, and Japan will bring new benefits of increased revenues and upgraded technology. Given the R&D structure of Taiwan’s auto electronics products and developmental trends in global auto electronics, if Taiwan auto component makers can utilize their current product development capability together with new technological applications, they will have considerable competitiveness in the car body electronics and driver information sectors. However, it must be noted that large amounts of R&D funds are required to develop auto electronics products, and Taiwan’s automotive component manufacturers are mostly SMEs. With limited technological and capital resources, a major challenge in the future will be for them to rapidly develop competitive products through international cooperation. IV. Investment Incentives To promote the rapid development of Taiwan’s industries, the government provides many kinds of preferential measures including tax incentives, R&D subsidies, and low-interest loans to assist members of the industry and attract and encourage foreign investment in Taiwan. Table 4. Incentive Measures to Encourage Investment in Taiwan Incentive Incentive Measure Leasing Tax Incentives Incentives for Newly Emerging Strategic Industries (Choice of one of two options: shareholder investment 19 Contact Information Industrial Development Bureau, Ministry of Economic Affairs http://www.moeaidb.gov.tw E-mail: deduction or five-year income-tax holiday Manpower training expense incentive (35% of spending deducted from taxable income for the year) R&D expense incentive (35 percent of spending deducted from taxable income for the year) Accelerated equipment depreciation (two-year depreciation) Deductions for equipment purchases and technology investments Duty-free import of equipment Income tax exemption for technology transfer or technological cooperation 20 service@moeaidb.gov.tw Tel: (+886-2) 2754-1255 Incentive R&D subsidies Incentive Measure Industrial Technology Development Program (ITDP) Small Business Innovation Research Program (SBIR) Contact Information Department of Industrial Technology http://doit.moea.gov.tw Tel: (+886-2) 2321-2200 Industrial Technology Development Alliance Program (ITDAP) Strategic Service Oriented Research & Development Program (SRD) Information Technology Applications Promotion Project (ITAP) Industrial Technology Innovation Center Program (MNCD) Multinational Innovative R&D Centers in Taiwan Program (MNCF) New Leading Product Development Project Business R&D Alliance Promotion Project Business Operating Headquarters Services Contact: solution@moeasmea.gov.tw 21 Industrial Development Bureau, Ministry of Economic Affairs http://www.moeaidb.gov.tw E-mail: service@moeaidb.gov.tw Tel: (+886-2) 2754-1255 Incentive Low Interest Loans Incentive Measure Industry Research and Development Loan Program Executive Yuan Medium-term Low Interest Loans Special Project Loans to Bolster SMEs Executive Yuan National Development Fund Loan Incentives Hsinchu Science Park Low-interest Loans Manpower Training International Talent Recruitment National Defense Reserve Officer Training R&D Substitute Service to fulfill Military Service Obligation Source: Compiled for this report 22 Contact Information Industrial Development Bureau, Ministry of Economic Affairs http://www.moeaidb.gov.tw E-mail: service@moeaidb.gov.tw Tel: (+886-2) 2754-1255 Council for Economic Planning and Development http://www.cepd.gov.tw Tel: (+886-2) 2316-5300 Small and Medium Enterprise Administration, Ministry of Economic Affairs http://www.moeasmea.gov.tw E-mail: solution@moeasmea.gov.tw Tel: (+886-2) 2368-6858 National Development Fund, Executive Yuan http://www.df.gov.tw E-mail: df@df.gov.tw Tel: (+886-2) 2389-0633 Hsinchu Science Park Administration Bureau http://www.sipa.gov.tw Tel: (+886-3) 577-3311 Department of Investment Services, Ministry of Economic Affairs http://hirecruit.nat.gov.tw E-mail: hirecruit@taitra.org.tw Tel: (+886-2) 2370-9687 National Defense Reserve Training Office http://rondi.mnd.gov.tw E-mail: mndsys@iii.org.tw Tel: (+886-2) 2736-8088 Ex. 3414 R&D Substitute Service Office, Ministry of the Interior http://rdss.nca.gov.tw E-mail: rdss@mail.nca.gov.tw Tel: (+886-2) 2736-6066 Ex. 206 V. Industry-Academia Collaboration in Taiwan Table 5 Web Industrial Development Bureau, MOEA www.moeaidb.gov.tw Department of Industrial Technology, MOEA www.doit.moea.gov.tw Department of Investment Services, MOEA www.dois.moea.gov.tw Institute of Transportation, MOTC www.iot.gov.tw Taiwan External Trade Development Council www.taiwantrade.com.tw (TAITRA) Taiwan Electrical and Electronic www.teema.org.tw Manufacturers’ Associaton (TEEMA) Industrial Technology Research Institute www.itri.org.tw (ITRI) Automotive Research & Testing Center www.artc.org.tw (ARTC) Institute for Information Industry (III) www.iii.org.tw Metal Industries Research & Development www.mirdc.org.tw Centre (MIRDC) Chung-Shan Institute of Science & cs.mnd.gov.tw Technology Automobile Electronics Consortium www.teema.org.tw Taipei CarTronics Promotion Office www.tca.org.tw (TCPO) 23