Vocabulary Ch #9 & 10

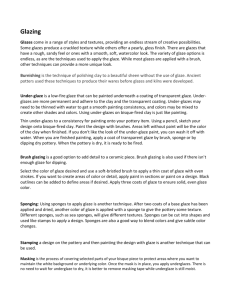

advertisement

Vocabulary Ch#10 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. Warping: this occurs during drying or firing. Fracturing: when the glaze is applied to thick and causes the ware to break. Shivering: a glaze defect: glaze which has cooled, split & peels away from the clay. Glaze: a coating used to seal & protect, glass like. Under Glaze: color (paint like) applied to clay which fires flat. Matt Glaze: a mature glaze that is smooth but without gloss. Kiln Furniture: equipment that is used in the kiln to hold ware during firing. Stacking the Kiln: loading the kiln with the maximum amount of ware. Electric Kiln: a furnace used for firing ceramic projects, this is one is the easiest to regulate the temp. Bisque ware: what clay is called after it has been fired one time. Vocabulary Ch #9 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. Blebbing: raised bumps on the surface, caused from improper kneading, Bloating: looks like blebbing but caused by insufficient oxygen in the kiln. Crazing: cracks all over the glaze fired piece, caused by contraction between the clay and glaze. Crawling: bare spots on the clay caused by contraction of the glaze, also known as beading. Peeling: glazes that are applied to heavy or projects that have not been washed before glaze is applied. Bubbles: glaze has been fired too rapidly, gasses from the clay try to escape yet get trapped in the glaze. Blistering: bubbles that pop and sharp edges are left on the surface of the glaze, known as cratering. Running: glazes put on too thick & slide down the surface of the project. Cracks: glaze defect, also known as exploding, these are caused by rapid water removal when firing. Shrinkage cracks: this happens in tall ware when the kiln is not heated evenly. Vocabulary Ch #9 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. Blebbing: raised bumps on the surface, caused from improper kneading, Bloating: looks like blebbing but caused by insufficient oxygen in the kiln. Crazing: cracks all over the glaze fired piece, caused by contraction between the clay and glaze. Crawling: bare spots on the clay caused by contraction of the glaze, also known as beading. Peeling: glazes that are applied to heavy or projects that have not been washed before glaze is applied. Bubbles: glaze has been fired too rapidly, gasses from the clay try to escape yet get trapped in the glaze. Blistering: bubbles that pop and sharp edges are left on the surface of the glaze, known as cratering. Running: glazes put on too thick & slide down the surface of the project. Cracks: glaze defect, also known as exploding, these are caused by rapid water removal when firing. Shrinkage cracks: this happens in tall ware when the kiln is not heated evenly.