c by ` -1-

advertisement

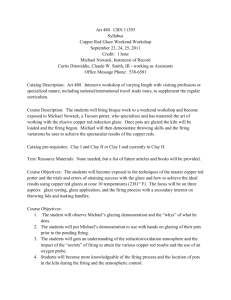

PAS~T. c 13 THES T S INVESTIGATION OF RED COPPER GLAZES by JL Hamilton Minnick Course IX-B r"SATU 1:7 E7 '"rl C T ITUT -1- E'- -- TE f ` F7n L T R1 A9 2 In accordance with t h e requirements for the degree of Bachelor o f Science, I herewith submit f o r your, e n t i , t f ed: "xnvestigstion Red Copper Glazes Q . __ I ACLKNOWLEEETI 7 T 'IT * INIT7OTTCT:0G * OEJECC _U . . . 9 4 OP TILL INVETILATION RI APPARATUS HETHOD OF OCEE4UFJ DBATk 4a . 9 ROEC&R"S \L . . . . .. . 4 4 LIEIQAItJE APSTRAOTO . I * * * . . V 't 4 4 7p 7 4 .4 Li .. PRE]COMM•yENL ATI........... L'1tkUJ1PJ * i V . . 4 a .4 4 4 4 4 4 . . 2 C 50 i; Ia ACKNOW.LEDGEMENT The author wishes to acknow-ledge his indebtedness- to Profressor -. 71. Norton 'under whose supervision this investigation was made. The kiln used was his deaign, a.nd his advice and suggestions tere invailuable. I :.:•:-.: ,, k 1. INTRODUCTION To we people of modern times, the many masterpieces of the ceramic art which have been preserved through the ages, never fail to gain admiration for the work of these ancient master craftsmen. It is difficult, oftentimes to un- derstand how they were able to produce such beautiful china, porcelain, and glazes with the very crude tools and facilities available to them in those forgotten times. We cannot doubt that the technique and methods used by them were flawless, for these examples of their art which we know and admire are perfect specimens of design and execution. To a student of artistic beauty, the mere handling and visual inspection of a beautiful glaze or a rare porcelain carries with it a certain satisfaction, but to anyone interested in reproduction of such ware, the charm of the piece lies in being able to understand the background of research and methods of Technology employed. 2. It is safe to say that the Chinese and Japanese were the first master potters and it is from them that the rest of the world has learned much of this art. Their porcelains and glazes are treasured even today for their exquisite beauty and texture. Among these glazes is one known variously as "rouge flambe", Chinese-red, sang de boeuf oY1 ox blood. It is the peculiar red glaze which is found on old Chinese porcelain and because of its unique color and difficulty of production has always been a source of particular interest to potters of many ages. Many have produced it with vary- ing degrees of success, but each one has offered conflicting reports of the methods used. It is still worthy of much added research and has been made the subject for investigation in this thesis. 3, OBJECT OF THE INVESTIGATION The object of this thesis was to investigate the Chinese red, or red copper glazes. In making such an investigation it is the conditions under which the glaze is fired which are of primary importance, as it is these firing conditions on which investigators disagree. With this in mind it was made the object of the thesis to investigate these conditions and study the changes wrought in the glaze by variation in their character. DESCRIPTION OF APPARATUS The investigator was very fortunate in having at his disposal a design and materials for building an electric furnace to be used as a kiln in the investigation. This furnace was the design of Professor F. H. Norton and was already in process of fabrication. It consisted of a round asbestos board base on which two pieces of pipe were attached in a vertical position as a frame. iiThe kiln itself was a cylindrical galvanized iron shell into which were fitted special refractory bricks of high kaolin content. These bricks are also excellent insulators and gave the kiln ideal heat retaining qualities. The open spaces between brick and shell were filled with a powder made by crushing pieces of this same type of brick. The base and top pieces of the kiln were round pieces of asbestos board and whole brick were also placed between these and the kiln chamber to form a completed closed and insulated srace. The kiln 5. chamber was made accessible from the bottom by a hole cut through the asbestos base and base bricks, and a frame sliding on the frame pipes carried a round piece of asbestos and brick which completely sealed the hole when in the closed position. At each corner of the hexagonal shaped kiln chamber a hole was drilled through from top and bottom each top hole thus coming in a vertical line with the one below. These were for the aus- tenitic stainless steel electrodes which made contact with the GlobaY heating elements within the furnace. After drilling these holes the interior of the kiln was coated with a semi liquid mixture of refractory cement which made a uniform surface and protected the refractory. This cement was made up of 50% burned clay grog and 50% Bennington kaolin, with sufficient water to give it a very soft consistency, Any expansion in the iron shell was relieved by springs which executed their force on the top cover bearing on the shell. Both top and bottom asbestos boards were grooved to accommodate the shell and form a good joint. As a matter of fact it was found necessary 6. to cement this joint in order to give an airtight seal. Constant pressure was executed on top and bottom of each electrode by a spring in the These form of a flat piece of phosphor bronze. also formed the electrical contacts to each electrode. These contacts were all connected at top and bottom by an insulated wire and from each of these a lead was taken to the source of power. This constituted parallel operation of the Globar elements which were designed to run on 115 volts, and draw 4.5 amperes at this voltage. Heating control was furnished by a variable resistance of the coil type which regulated the current flowing to the Globars. A Platinum - Platinum 10% Rhod m thermo- couple was used in conjunction with a Leeds and Northrop indicating potentiometer for measuring the temperatures in the kiln. The thermo-couple was inserted in the kiln through a hole bored through from the top. 79 Power was taken from the Institute system through an auto transformer delivering voltage to a switchboard in 15 volt steps. It was thus possible to choose any particular primary heating potential. Although not absolutely essential to the experiment in a quantitative way an ammeter was used.in series with the load. It furnished an excellent indicator of the effectiveness of the electrical contacts within the kiln and under severe reducing conditions showed whether an excess of carbon was being deposited on the walls of the kiln. 8. METHOD OF PROCEDURE In conducting this investigation it was necessary to have a kiln in which to fire the glazes under observation and to this end work was started on the kiln already described and illustrated. In the meantime, and while working on the kiln, research work in the literature available on this subject was resorted to in an effort to discover glazes and methods which had produced the desired result. When the kiln was completed two glazes had been selected and frits were made of these. The sample tiles on which glaze was applied were then fired to determine the maturing point of the glaze. of the When this was ascertained the remainder runs were made under varying conditions of atmosphere and heating rate with the object of finding those conditions under which the best glaze was produced. In doing this, runs were made with slow heating, fast heating, oxidizing from start, reducing from start, and combinations of all, both under steady conditions of atmosphere and alternating between reducing and oxidizing. It is on these firing conditions which most investigators disagree but that reducing conditions are essential at some time during the burn is conceded by all. Before firing any glazes in the kiln a heat run was made to determine the heating characteristic of the kiln, and following this the furnace was allowed to cool naturally while closed to determine its cooling characteristics. BASIC PRINCIPLE INVOLVED A glaze containing copper oxide will fire to a light blue or blueish green when fired under completely oxidizing conditions. In order to produce the red color in the glaze it is necessary to fire the glaze under conditions which will reduce the cupric oxide and leave finally divided metallic copper dispersed throughout the glaze. It is not enough, however, to simply reduce the cupric oxide but to maintain it in its reduced state and to prevent the other 10, chemical reactions between the metal thus formed and the silicates present in the mo1lten glaze. It is this consideration which requires adjustment and control of the firing conditions. 11. DATA The glazes used were the following: 1. Keramos glaze maturing at a low temperature. .5 K2 0 .5 Ca 0 2.5 Si 02 .1 Al 0 2 3 1.O B 0 3 2 Add .5% C u 0, and frit all but .1 clay Molecular weight 4W 305.2 Frit recipe: Parts Constituent Si 138 02 K2 0C0 3 69 Ca C 03 50 124 B2 03 C u 0 .005 x 1.5 305.2 Yield of frit Maturing temperature of glaze - 125 grams S17750 F 12. 2. Sprechsaal glaze .9 Na 2 0 .15 B2 0 3 0 .10 Al 2 0 3 .1 Ba Add .5% 0 u 0, and frit all but Molecular weight : 4.0 Si 02 .1 clay 332.0 Frit recipe: Parts Constituent 57.1 Borax - Na 2 B 4 07 .10H2 0 C 0 Na 3 2 63.6 19.7 Ba C 03 Si C u 0 , 228.0 0 .005 x 1.7 332 82.0 grams Yield of frit Maturing temperature of glaze - 2200 o F 13. Keramos Molecular weight .5 x 94.2 47. 1 .5 x 56.1 28. 05 2.5 x 60.1 1.0 x 101.9 .1 x 101.9 - 150. S 305. 2 Addition of C u 0 .005 x 305.2 = 153 grams. : 125 grams Molecular weight of frit Clay addition - 69. 6 10. 19 - Molecular weight Yield of frit 25 - 283 (.1 x 258.1) ( 125 ) 283 - 11.5 grams 14. Sprechsaal Molecular weight .9 x 62 .1 x 153. 4 55. 8 S15. 34 .15 x 69.6 : 10. 44 .10 x 101.9 - 4.00 x 10. 19 S240.4 60.1 Molecular weight = 332.17 Addition of C u 0 - .005 x 332.17 - Yield of frit - 1.66 grams 82 grams Molecular weight of frit - 155 (.1 x 258.1) (82) Clay addition S6.8 grams. S 2 x 155 After fritting the glaze was ball milled to pass 100 mesh screen and excess water dried off. Portions of the frit were next in water with the proper portion of the clay to be added and applied to small pieces of tile with a brush or spray. The tiles were placed on small kiln plates moulded especially for the purpose from a 50-50 mix of 80 grog and kaolin with a little dextrin added for bonding. Specimen Tiles Designation of specimens is as follows: #3 S F designates that a tile glazed with the third (#3) batch of the Sprechsaal (S) glqze mixed from the frit, the letter (F) distinguishing it from other tiles glazed with the same batch. #3 K B follows the same plan of designation for the Keramos glaze. 16. When coke was used for the reducing medium it was placed on a furnace plate and entered the kiln with the specimens. Air, gas, and hydrogen were blown into the kiln chamber through a 3/16" hole drilled through the shell about in the middle of the kiln. Slow cooling was at a rate of 7.2 my. per hour and natural cooling by cutting the power off completely. Mature glaze #1 K B Run completely oxidizing. #2 K B Glaze matured oxidizing and cooled to 1480oF. Reduced at 14800F for 20 min. Cooled oxidizing. #3 K A Oxidizing to 60000. reducing. Rest of run completely Hold at maturing temperature for 1 hr. #4 K A Alternating conditions starting at 1100 0 F to maturity. Cycle of 5 min. reducing, 15 min. oxidizing. 17. #4 K B Coke for reducing. turity. #4 K D Heat rapidly to ma- Remove from kiln. Coke for reducing. Soak at 1775OF for 25 min. #4 K E Coke and gas reducing. start. Coke in oven from Run rapidly to maturity. One cycle of 1 min. gas reducing and air for 5 min. #4 K E2 Coke reducing to maturity, gas reducing for 1-1/2 min., soak for 1/2 hr. oxidizing. #4 K F Cool naturally to 12300 F. Hydrogen reducing during complete run. Soak 1/2 hr. at maturity, cool slowly. #4 K H Mature oxidizing. Cool to 1450 F. Re- duce alternating - gas 1 min. air 2 min. for 4 cycles. #4 K M Mature and cool to 1450 0F. Reduce at 1450oF for 5 min., oxidize 1 min., reduce 10 min. #1 SB Not mature. 0 Heat to 2000sF, cool to 1500 OF. (1). Reduce 5 min. (2). Oxidize 2 min. (3). Reduce 10 min. (4). Oxidize 1 m in. 18. #1 S C Soak 1/2 hr. at 2000 0 F, cool to 1500 0F. (1). Reduce 5 min. (2). Oxidize 1 min. (3). Reduce 10 min. (4). Oxidize I min. Cool oxidizing to 1200 F. #1 S D Soak for 1/2 hr. at 2150 0 F, cool to 1550oF (1). Reduce 20 min. (3). Reduce 15 min. Cool reducing (2). Oxidize 2 rmin. to 1215oF. Cool oxidizing to 1000F. #2 S B Straight oxidizing, no matured. 1800oF #3 S B Soak 1/2 hr. at 2000 0 F, cool slowly to 15000F #3 S C (1.) Reduce 10 min. (2). Oxidize 1 min. (3.) Reduce 10 min. (4). Oxidize 1 min. Soak 1/2 hr. at 2075 0 F, cool to 1450oF. (1). Reduce 20 min. (2). Oxidize 2 min. (3). Reduce 15 min. Cool reducing to 12250F. Cool oxidizing to 1050F. #3 S E Over burned. Soaked 20 min. at 2150 0 F, cool to 1600F. (1). Reduce 30 min. (2). (3). Reduce 15 min. Cool reducing to 12000F Cool oxidizing to 10500F. Oxidize 3 rmin. O 0 #4 S B Heat to 2150 F for 10 min., cool to 1450 F (1). Reduce 20 min. (3). (2). Oxidize 2 min. Reduce 20 min. Cool reducing to 1200oF. Cool oxidizing to 1050Fo #4 S H Heat to 22000F for 5 min., cool to 15000F. (1).Reduce 5 min. (3). Reduce 10 min. Cool reducing to 1550°F Cool oxidizing to 1350OF (2). Oxidize 1 min. These glazed specimens may be inspected at the office of Professor F. H. Norton. 20. CONCLUSIONS 1. Successful production of the red glaze depends first on complete maturity of the glaze at the lowest possible maturing temperature. This can only be done without overburning by holding the kiln temperature at a steady value for sufficient time to insure complete maturity. Factors which influence the length of time are thickness of body, thickness of glaze, and composition of glaze. If the glaze is rich in easily fusible oxides then both the temperature at which it matures and the length of soaking time at this temperature will be reduced. Without this complete maturing of the glaze it is difficult for the reducing reactions to take place in the glaze and the resulting colors are muddy and lustreless at best. From the results obtained red glazes will be produced when first fully matured and then reduced at some lower temperature. Both the maturing temperature and that for reduction are dependent on the glaze composition. 2. The manner of applying the glaze to the pile does not seem to influence the result. 3. The rapidity of heating to maturity and cooling from it likewise does not seem to influence the results. 4. The black color of some of the glazes is due to large amounts of metallic copper from excessive reduction. 5. The greenish spots dispersed in the red are caused by a cupric oxide glass which is rich in insoluble silicates of copper. These segregate out and appear as the green spots. 6. Long soaking of the glaze at the maturing temperature has not effect on the result. RE COMMENDATI ONS The results of this investigation lead the author to believe that useful information could be obtained from further study carried on in the following lines: 1. More varied reducing atmospheres at differ- ent temperature ranges. 2. Trial of other glazes with methods used by successful investigators. 3. Measurement of kiln temperatures with an optical or radiation pyrometer because it was found that at high temperatures under reducing condition the thermocouple was far from accurate. 4. Application of the glaze on different bodies. 5. Glazes with foreign oxides such as tin, uranium, iron, titanium and others. 23. BIBLIOGRAPHY "On the Change In Colored Glazes by Reducing at Low Temperatures" by Hans Eska, Sprechsaal, May 22 and May 29, 1930. "Coloring Agents in Glasses and Glazes" by Sir Herbert Jackson, Proceedings of the Royal Institution of Great Lritain, Vol 25, 1927, pp. 230-241. "Collected Writings of H. A. Seger", Vol. 2, pp. 733746. "China Red Glazes" by F. Wurts, Keramos 9 (4), 1930, pp. 121-126. "Experiments on Red Copper Glazes" by Eberhard Breitenfeldt, Keram. Rund., 37, 1929, pp. 393-394. 24. LITERATURE ABSTRACTS The abstracts included here are from those works which seem to be the most straightforward in their treatment of the subject. PROCEEDINGS OF THE ROYAL INSTITUTION March 4, 1927. Coloring Agents in Glasses and Glazes. Sir Herbert Jackson. It is worth while to refer to one property of cuprous oxide. This oxide does not form salts with acids except the halogen acids. With oxygen containing acids, if it reacts with them, metallic copper is produced along with a cupric salt of the acid. This action takes place in the glaze under the influence of silica with production of metallic copper dispersed through a greenish cupric oxide glass. The brilliant 'sang de boeuf" glazes are made under conditions which tend to reduce any cupric oxide which may be formed so that the glass is not 25. rendered dingy by a green tent due to dissolve cupric oxide. Very little copper is used - in the neighbor- hood of .5%. Under the microscope some pieces are red, others purple or blue and some like neutral glass. A black glass might be a mixture of red copper glass and green cupric oxide glass through which but little light is transmitted. "Change in Colored Glazes by Reducing at Low Temperatures" by Hans Eska - Sprechsaal, May 29, 1930. Foreign oxides as well as material used for reducing, influences the production of the red color. The color is produced by the little copper crystals which lie in the surface of the glass. In the glaze the fields still free near the crystalized places are light green to dark green. Reducing substances and cooling play a role. A finer grinding of the glazing materials increases t1ne ability of dissolving and thereby the regularity of the melt. 26. The formation will proceed more evenly and the color of the glaze appears more uniform. Some materials are not wholly miscible in their liquid states, which is proven by the formation of the green segregations. "Collected Writings of H. A. Seger" - Vol. 2 pp. 733- 746. Segar does not agree with many of his contemporaries regarding the production of the red color. According to him it is not sufficient to reduce by a simple continuous reduction, but rather to alternate between reduction and oxidation. If reduction is accomplished with illuminating gas a part of its carbon is deposited due to decomposition of the gas, which surrounds the particles preventing fusion. If glazes, reduced in this manner are heated in air, the carbon is burned out, but at the same time the copper segregated out is also oxidized to cuprous oxide and the glaze is enabled to fuse. glazes are always produced. In this manner red The quantity of copper oxide which is used is also a great importance for the beauty of the color. In his experiment he used a content of corper between .5 and 1% and always obtained very good results, With a content of .5% of copper oxide to 100 parts of a porcelain glaze, the glaze is colored red and perfectly opaque. After the ware was glazed and had been set so that the smoke could reach it freely at first a fire as oxidizing as possible is maintained. As soon as a dark red heat shows in the kiln, as much smoke as possible is produced and continued up to a temperature at which the glaze begins to vitrify. This is followed by short periods of oxidation kept up at short intervals - about 1 to 2 min. for each 1/4 of an hour; between these, hoVever, a strongly reducing kiln atmosphere must prevail. This mode of firing must be continued until the glaze has become densed and somewhat glossy. There upon the burning may proceed with oxidizing or reducing kiln conditions up to the close of the burn. C-). APPEND .I X ion of Ltescip A.Galai 2zead B. A;e etoo C. - ID. Pip E StOL G, .u si -0 in hell uscw a sac .tor oe r" &2Tmin% .2<aL. bk? kiI2 &J;>iLg Gilbai: hceati½g elc.>"t N il bhme poe Furnace Diagram.