2 Fiber optic sensors for temperature measurement

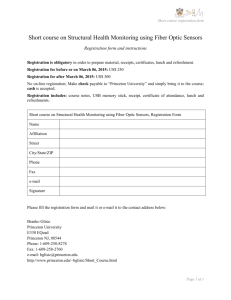

advertisement

Fiber optic sensors Report in TFFY22 Optoelectronics Per Eklund Staffan Rydblom perek079@student.liu.se 771119-8213 stary952@student.liu.se 750728-2437 Abstract In this report, several different fiber optic sensors are examined. The intent of the authors is not to give an exhaustive overview of everything in the field of fiber optic sensors, but merely a few examples illustrating their usefulness for completely different purposes. We discuss ways of measuring temperature, both in a simple way and using a dual Fabry-Perot interferometer, the later giving extremely high sensitivity. Bragg gratings are also described briefly, and we give a thorough description of a strain sensor for use on an aircraft wing. This strain sensor is also based on a Fabry-Perot interferometer, but it is coupled to a neural network. Table of contents 1 INTRODUCTION .............................................................................................................................................. 3 1.1 BASICS ........................................................................................................................................................... 3 1.2 INTENSITY MODULATED SENSORS .................................................................................................................. 3 1.3 PHASE MODULATED SENSORS......................................................................................................................... 3 2 FIBER OPTIC SENSORS FOR TEMPERATURE MEASUREMENT ....................................................... 4 2.1 INTRODUCTION .............................................................................................................................................. 4 2.2 A SIMPLE EXAMPLE ........................................................................................................................................ 4 2.3 INTERFEROMETRIC TEMPERATURE SENSORS .................................................................................................. 4 2.4 A FIBER OPTIC FABRY-PEROT TEMPERATURE SENSOR.................................................................................... 5 3 BRAGG GRATING OPTICAL SENSORS ..................................................................................................... 6 4 AERODYNAMIC TESTING OF A SMART COMPOSITE WING USING FIBER-OPTIC STRAIN SENSING AND NEURAL NETWORKS ........................................................................................................... 6 5 CONCLUSIONS ................................................................................................................................................ 7 REFERENCES ...................................................................................................................................................... 7 1 Introduction 1.1 Basics Basically, there are two main types of fiber optic sensors used today. They are the phase modulated and the intensity modulated sensors. Intensity modulated sensors works by letting a physical disturbance cause a change in the received light through an optical fiber. Phase modulated sensors work by comparing the phase of light in the sensing fiber with a reference fiber in an interferometer. Phase modulated sensors are in general much more accurate than intensity modulated, but are also much more expensive due to the advanced electronics needed to process the interferometer information. Fiber optic sensor are also classified as extrinsic or intrinsic. In an intrinsic sensor, the fiber itself is the sensing element(the fiber is directly affected by the measurand). In an extrinsic sensor, the fiber simply transports light to or from the sensing element. Compared with other types of sensors, some of their main advantages are their high sensitivity and the possibility to measure in hostile environments (heat, dangerous chemicals, ....). In this report, we study several examples of fiber optic sensors, both basic examples and sensors from recent scientific publications. Our examples are taken from different areas: they are used to measure different quantities and are based on different physical principles. But we also have examples where the same physical principle(we have chosen the Fabry-Perot interferometer) is used in completely different areas: in chapter 2 as a temperature sensor, and in chapter 4 together with a neural network to measure the strain on a aircraft wing. 1.2 Intensity modulated sensors An intensity-modulated sensor must change the intensity of the measured light in a way that can be predicted. There are several ways of achieving this. The simplest one is the transmission or reflection concept. Other concepts are those of micro bending intrinsic sensors. The transmission/reflection concept is normally used as a digital switch but can also be used as an analogue detector. It works by simply move the detector or a mirror a distance R away from the fiber center. When an optical fiber is bent, small amounts of light will be lost as the angle of incidence between the transmitted light and the fiber’s walls change due to loss of total internal reflection. This is called micro bending and is a way to detect a displacement in a closed optical path. As the path is closed, the micro bending optical sensor can be used in dirty environments. The intrinsic sensors have the advantage that the intensity can be changed without any actual movement of the fiber. Instead, they use the chemistry in the core glass by changing e.g. the refractive index, absorption through the walls or polarization to cause the change in intensity. Important applications of intrinsic sensors are temperature and pressure measurement. Another important technique that we will investigate more further in this report is that of Bragg gratings. When it comes to temperature sensing, we will describe different techniques, both extrinsic and intrinsic. 1.3 Phase modulated sensors Phase modulated sensors consist in general of a coherent laser which inject light into two single mode fibers. If the environment perturbs one or both fibers differently, a phase shift will occur that can easily be detected. Even an extremely small perturbation will be possible to detect using this technique which means that the sensors can be made very accurate. Interferometry-based sensors will be described more thoroughly when we discuss temperature sensing. 2 Fiber optic sensors for temperature measurement 2.1 Introduction There are many types, both extrinsic and intrinsic, of fiber optic sensors that are used for measuring temperature. They may be characterized in several ways. The modulation which is used to code the temperature information may be considered, or the classification could follow the nature of the sensor: interferometric sensors, resonant sensors, wavelength encoding, distributed or simple intensity-ratio-based devices. In this section we will limit ourselves to studying a few interesting examples that illustrate different sensing principles. 2.2 A simple example A simple but useful fiber optic temperature sensor is shown in figure 1. The basic type has been available since the mid-1980s[4]. The basic idea is to terminate the fiber in a capsule at a reflecting surface. On the other side of the surface, there is an air bubble. This bubble will change dimensions with temperature, thus allowing the thermosensitive cladding of the fiber to expand or contract. Consequently, the numerical aperture and the attenuation of light in the fiber will change with temperature. Even in the earliest version of the sensor, a sensitivity better than 0.1 degrees Celsius was readily obtained. This is obviously not impressive compared with the interferometric sensor described below, yet it is not bad considering how simple the device is. Its disadvantage is that the temperature sensing range is somewhat limited. However, this is not a problem in e.g. biological and medical applications, where the interesting temperature range is relatively narrow. Figure 1. A simple fiber optic temperature sensor. 2.3 Interferometric temperature sensors Fiber optic interferometric techniques are applicable for measuring almost any physical quantity. Since interferometry yields high resolution measurements of length, fiber optic tech- niques have been developed where a measurand is converted into a change of displacement. Temperature is one such measurand, and for anyone in need of high-precision temperature measurements, fiber optic interferometers is an important alternative. Fiber optic versions of all the well-known interferometers[3] are available: Michelson, FabryPerot, Sagnac and, perhaps most common, the Mach-Zender interferometer. The basic idea is simple: send light through two fibers, a reference fiber and a sensing fiber. As the physical dimensions of the sensing fiber are changed by the measurand(temperature) there will be a phase difference between the light traveling through the two fibers. The phase difference can be measured by "counting fringes", transformed into a physical dimension change which, in turn, gives information about the measurand. 2.4 A fiber optic Fabry-Perot temperature sensor As an example of a fiber optic temperature sensor, we discuss the Fabry-Perot based sensor published by Lee and Taylor[5] in the early 1990s. They have later described improvements[6,7]. The basic principle is shown in figure 2. Figure 2. Principle sketch of a dual fiber-optic Fabry-Perot sensor. They use an LED as a (low-coherence) light source. The advantages of using a low-coherence source in comparison with a semiconductor laser are, among others, that there is no need to compensate for thermally induced shifts in the emission wavelength of the laser, that we are not limited to select device for single-mode operation, and of course that LEDs are cheaper than lasers. These advantages will have to be paid for with a somewhat smaller sensitivity. The sensor uses two Fabry-Perot interferometers(FPI), one for sensing and one for reference. Similar sensors using other types of interferometers also exist[8,9]. Light from the LED is modulated by reflection, first by the sensing FPI and then by the reference FPI. After a bit of mathematics, one can show that the power output is proportional to (1 + 0.5cos p) where p is the phase shift due to the perturbation applied to the sensor interferometer. Measurements show that the phase shift is linearly dependent on temperature in a range of 26 to 108 degrees Celsius. The sensitivity obtained with this dual FPI sensor is somewhat smaller than that of a single FPI sensor using a laser source. This is due to a lower fringe visibility and a lower optical power being coupled into the fiber. Yet, excellent performance is possible: a sensitivity of the order of 0.0002 degrees is calculated at the maximum sensitivity point(compare this with 0.1 degrees for the simple sensor described earlier). The reduction in fringe visibility can, however, reduce the temperature range of the sensor. This drawback can, to some extent, be compensated for by shortening the FPI length, which varies with temperature. This variation is the reason of the lowering of fringe visibility with increasing temperature. 3 Bragg grating optical sensors Coupling resonance between modes will occur when 2 , where k1 and k 2 are the k1 k 2 modal wave-vectors given by ki kni 2ni / and is the grating pitch. In a single-mode optical fiber n1 n2 and we get the Bragg condition / n1 2 . If a grating is done inside an optical fiber, wavelengths that satisfy the Bragg condition are strongly reflected while other wavelengths are transmitted. If the fiber is exposed to strain (displacement) both the spacing between the gratings and the refractive index will change. Therefore, the strain will cause a change in the reflected beam’s wavelength as well as modulate the reflected beam proportional to the strain. The strain sensor can be made so sensitive that even small changes in temperature can also be measured. A Bragg grating is normally 1 to 2 cm long. 4 Aerodynamic testing of a smart composite wing using fiber-optic strain sensing and neural networks Often it is desirable to measure strain over a large surface like an aircraft fuselage or a building structure. In such cases it is common to arrange the sensors in a sensing network or “smart skin” embedded in a composite structure. Once installed, it is possible to monitor the structure’s strain and temperature. Below is an application of fiber-optic sensors as described by Lunia et al.[11]. The ability to predict strains under varying air loads on a wing structure is very valuable in aircraft design and operation. Unfortunately, the strains on an aircraft wing are strongly nonlinear and depend greatly on environmental conditions such as rain, icing and age of material. Therefore, there still do not exist any solution to measure and monitor this in real time. A smart wing using fiber optic sensors in combination with a neural network would have the potential to monitor strain and provide the pilot with unique information in real time. In this case, an extrinsic Fabry-Perot interferometer sensor was used and placed in the wing root. An expression of the strain at the root can be written in terms of the root bending which in turn depends on the lift and the center of pressure in distance units from the root. The air speed and angle of attack was measured to teach the neural network. This configuration was exposed to a range of wind speeds and angles of attack in a wind tunnel. After 1000 training sequences, the sum squared network error had decreased by four decades. The trials were very promising and show the potential of a fiber optic sensors using a neural network but to be able to measure and predict a non-linear phenomenon such as stall more than one sensor must be used and placed on carefully chosen locations. Our suggestion is to use a network or "smart skin" of intensity modulated Bragg grating sensors integrated in the wing structure in combination with a neural network. This would have the potential of giving the aircrew real-time information, never before available, about the condition of the aircraft. 5 Conclusions In this report we have discussed several different types of fiber optic sensors, their drawbacks and merits. However, the main conclusion can be drawn from the sheer number of applications. Fiber optic sensors can be used to measure practically any physical quantity, and there is a seemingly infinite number of ways to do it. There are very simple fiber optic sensors as well as expensive state-of-the-art equipment with extremely high sensitivity. They can be used alone or in networks. The general idea is that fiber optic sensors are, or shortly will be, found "everywhere". References [1] Wolfbeis, O.S.(ed.) Fiber optic chemical sensors and biosensors, volumes I-II, CRC Press 1991 [2] Culshaw, B. and Dakin, J. (eds.) Optical fiber sensors, volumes I-IV, Artech House 1989-1996 [3] Hecht, E. Optics, Addison-Wesley 1987 [4] Brenci, M. et. al. Proc. SPIE, 701, 216, 1986 [5] Lee, C. and Taylor, H. J. Lightwave technology Vol.9, 129, 1991 [6] Lee, C., Taylor, H., Choi, H-S. Optics letters Vol. 22, 1814, 1997 [7] Fiber Dynamics, Inc. home page: www.fiberdynamics.com [8] Brooks et. al., J. Lightwave technology Vol. 5, 1014, 1987 [9] Kersey, A.D. and Dandridge, A. J. Inst. Electronic and Radio Eng., Vol.58, S99, 1988 [10] Krohn, David. The photonics design and applications handbook 1998 p. 203-208. [11] Lunia, et. al. Smart materials and structures, 9, 2000 p. 767-773