eprint_4_3983_1444

advertisement

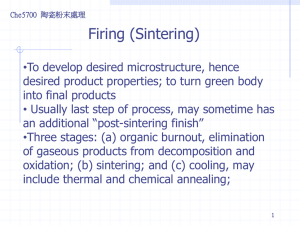

Lec. No. (23) Nanophase ceramic composites The application of ceramics has infiltrated almost all fields in the last 20 years, because of their advantages over metals due to their strong ionic or covalent bonding. But it is just this bonding nature of ceramics that directly results in their inherent brittleness and difficulty in machining. In other words, ceramics show hardly any macroscopic plasticity at room temperature or at low temperatures like metals. Hence, super plasticity at room temperature is a research objective for structural ceramics. In recent years, many researches have been carried out to investigate nanophase ceramic composites. Depending on the matrix grain size, nanophase ceramic composites can be classified in two fundamental groups. One is composed of micro meter sized matrices dispersed with a nanometer second phase, In this group, the second phase plays a crucial role that affects the microstructure and the properties. it has divided it into three types – intragranular, intergranular and intra-/intergranular – trying to relate the distribution of the second nanophase in the matrix and it arises improvements in toughness, strength at room temperature and high temperatures, creep strength and thermal shock resistance by incorporating nanocrystalline dispersion in a microcrystalline matrix. The other group of nanophase ceramic composites is nanocrystalline matrix composites, also called nanoceramics, in which the matrix grain size is below 100 nm. The nano– nano type microstructure will be formed when the second phase is also nano-scaled. Nano ceramics exhibit promising properties due to the changes in deformation mechanisms when the grain size is reduced to the order of 100 nm. The superplasticity of nanocrystalline CaF2 and nanocrystalline TiO2 at low temperatures, indicates that ceramics are learning to ‘bend’ instead of fracture. Furthermore, nanoceramics also show high toughness, in which a novel toughening mechanism called Ferroelectric Domain Switching is recognized, different from that in micro– nano type ceramic composites. Micro–nano type ceramic composites In early nanocomposites, hard and strong dispersoids, such as SiC, Si3N4, TiC, etc., were mainly incorporated into the matrix to improve the mechanical properties. But in later years, enhancement of fracture strength was also achieved by addition of even soft and weak dispersoids like metals, graphite and h-BN . The density, microstructure and mechanical properties of nano-sized particulate dispersion nanocomposites were strongly dependent on the volume fraction of particulate dispersion and sintering conditions. Hard nanoparticles usually have a higher sintering temperature than that of the matrix, so that the sintering temperature is increased with increasing hard-particulate content. In Al2O3/SiC systems, only 5 vol% SiC incorporation can evidently cumber the densification process. The nearly full densities attained by hot-pressing (HP) were achieved at 1600°C for 5 vol% SiC, at 1700°C for 11 vol% and at 1800°C for up to 33 vol% . In general, particles disperse according to their grain size and the variety of the matrix. For Al2O3/SiC, finer particles disperse within the matrix grains and larger particles at the grain boundaries. The critical grain size is typically 200 nm. For the MgO/SiC, Al2O3/Si3N4 and natural mullite/SiC composites, nanoparticles homogeneously disperse within as well as at the grain boundaries, The Al2O3/SiC, Al2O3/Si3N4 and MgO/SiC nanocomposites give a notable improvement in high-temperature strength up to and over 1000°C. In particular, the greatest improvement in high-temperature strength was observed for the MgO/SiC nanocomposites . It is well known that grain boundary sliding and/or cavitation are responsible for the high temperature strength degradation of oxide ceramics. Thus, the enhancement in strength at high temperatures is mainly due to the prohibition of the grain boundary sliding or cavitation by the dispersions within the matrix grains. Lec. No. (24) Nano–nano type ceramic composites Nanocrystalline materials form an exciting area of materials research because bulk materials with grain size less than 100 nm have properties not seen in their microcrystalline counterparts. But the brittleness of nanoceramics has limited their potential for use in structural applications, namely, research on nanoceramics shows that they are not inherently tougher than their microcrystalline counterparts. Many strategies have been proposed to improve the mechanical properties of nanoceramics by using reinforcement by a second-phase addition and hybridization to develop nanocrystalline matrix composite materials. Metal nanoparticle dispersed nanocomposites The mechanical properties of ceramics were improved by the addition of nano-sized metal particles that were dispersed in the ceramic matrix. Ceramic/ metal nanocomposites consisted of an oxide ceramic and either refractory metal such as in the Al2O3/W, Al2O3/Mo and ZrO2/Mo systems . These composites were fabricated by hot-pressing fine ceramic and metal powder mixtures or by reducing and hot-pressing the matrix and metal oxide powders . Lec. No. (25) Fabrication of nanoceramics Research on processing fully dense bulk nanoceramics and nanocomposites is attracting more and more interest. There have been some low-cost but effective processes to obtain nano-sized ceramic powder and nanocomposite powders, such as sol-gel, micro emulsion, codeposition and high-energy ball-milling (HEBM). One of the principal problems is the inability to consolidate nanopowders to high relative density without grain growth. To obtain the dense bulk nanoceramics, it is essential to decrease either sintering temperature or retaining time at the highest point, or both HP, HIP, high-pressure sintering and fast consolidation techniques such as microwave sintering and spark plasma sintering (SPS) have been employed. Among these techniques, high-pressure sintering seems to be the best way of obtaining fully dense nanoceramics at the present time. The application of high pressure over 1–8 GPa results in a decrease of the temperature ,within which fully dense compacts can be obtained without grain growth or with only very limited grain growth. For Al2O3 based nanoceramics, success in achieving such fine grain size can be mainly attributed to two factors; Firstly, lower sintering temperature no doubt leads to lower coarsening. Secondly, γ → α transformation before sintering is quite important. This transformation is known to be nucleation controlled, Also, the presence of the second phase helps to restrain the grain growth. Fast consolidation techniques, such as microwave sintering and plasma activated sintering (PAS), can enhance sintering and reduce the time available for grain growth. It allows very fast heating and cooling rates, very short holding times, and the possibility of obtaining fully dense samples at comparatively low sintering temperatures, typically a few hundred degrees lower than in normal hot pressing. Unlike the first-generation spark sintering and the second-generation PAS, SPS can result in better control of the microstructure and properties of materials in terms of sintering temperature and time. It is a pressuresintering method based on high-temperature plasma (spark plasma) momentarily generated in the gaps between powder materials by electrical discharge at the beginning of on–off DC pulsing. In this process, powders are loaded into a graphite die and are heated by passing an electric current through the assembly. These processes have now been developed beyond the production of small objects with simple shapes, as continuous production of compacts of complex geometry and of pieces with diameter larger than 150 mm has been achieved. Despite the fact that a uniaxial pressure is applied, green bodies of complex geometry can be exposed to a ‘pseudo-isostatic’ pressure when embedded in freeflowing electrically conducting particulates that act as a pressuretransmitting medium inside the die. By designing the mold, a temperature gradient along the direct current can be obtained, which is advantageous to simultaneously consolidating components with different sintering temperatures .