1 - American Foundry Society

advertisement

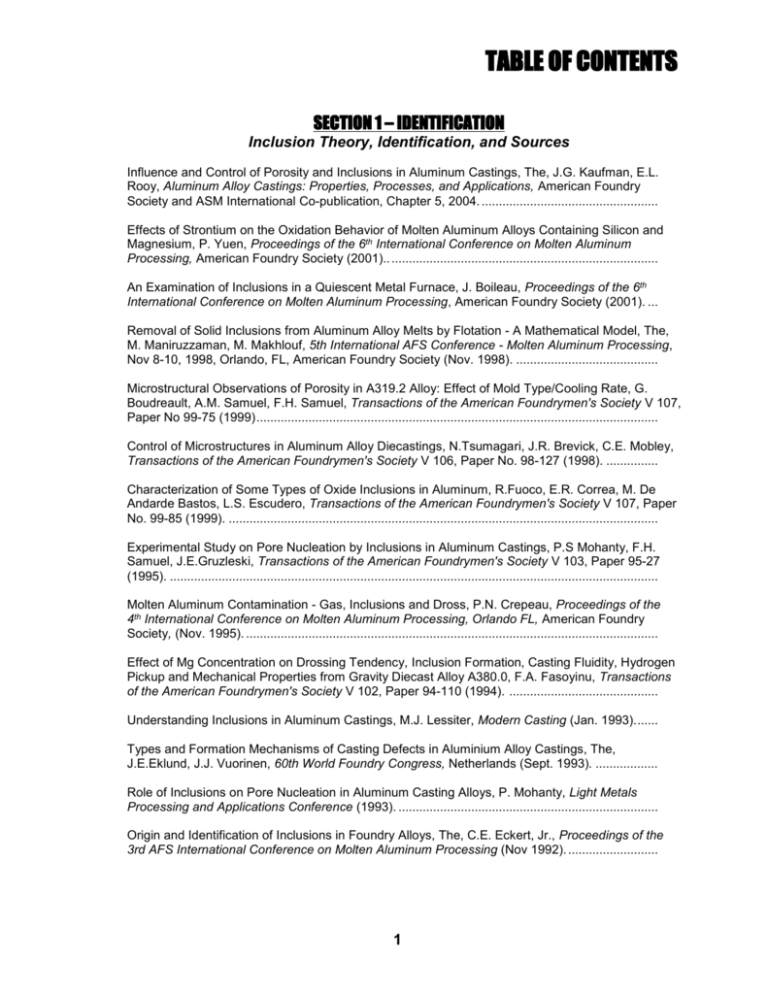

TABLE OF CONTENTS SECTION 1 – IDENTIFICATION Inclusion Theory, Identification, and Sources Influence and Control of Porosity and Inclusions in Aluminum Castings, The, J.G. Kaufman, E.L. Rooy, Aluminum Alloy Castings: Properties, Processes, and Applications, American Foundry Society and ASM International Co-publication, Chapter 5, 2004. ................................................... Effects of Strontium on the Oxidation Behavior of Molten Aluminum Alloys Containing Silicon and Magnesium, P. Yuen, Proceedings of the 6th International Conference on Molten Aluminum Processing, American Foundry Society (2001).. ............................................................................. An Examination of Inclusions in a Quiescent Metal Furnace, J. Boileau, Proceedings of the 6th International Conference on Molten Aluminum Processing, American Foundry Society (2001). ... Removal of Solid Inclusions from Aluminum Alloy Melts by Flotation - A Mathematical Model, The, M. Maniruzzaman, M. Makhlouf, 5th International AFS Conference - Molten Aluminum Processing, Nov 8-10, 1998, Orlando, FL, American Foundry Society (Nov. 1998). ......................................... Microstructural Observations of Porosity in A319.2 Alloy: Effect of Mold Type/Cooling Rate, G. Boudreault, A.M. Samuel, F.H. Samuel, Transactions of the American Foundrymen's Society V 107, Paper No 99-75 (1999) .................................................................................................................... Control of Microstructures in Aluminum Alloy Diecastings, N.Tsumagari, J.R. Brevick, C.E. Mobley, Transactions of the American Foundrymen's Society V 106, Paper No. 98-127 (1998). ............... Characterization of Some Types of Oxide Inclusions in Aluminum, R.Fuoco, E.R. Correa, M. De Andarde Bastos, L.S. Escudero, Transactions of the American Foundrymen's Society V 107, Paper No. 99-85 (1999). ............................................................................................................................ Experimental Study on Pore Nucleation by Inclusions in Aluminum Castings, P.S Mohanty, F.H. Samuel, J.E.Gruzleski, Transactions of the American Foundrymen's Society V 103, Paper 95-27 (1995). ............................................................................................................................................. Molten Aluminum Contamination - Gas, Inclusions and Dross, P.N. Crepeau, Proceedings of the 4th International Conference on Molten Aluminum Processing, Orlando FL, American Foundry Society, (Nov. 1995). ....................................................................................................................... Effect of Mg Concentration on Drossing Tendency, Inclusion Formation, Casting Fluidity, Hydrogen Pickup and Mechanical Properties from Gravity Diecast Alloy A380.0, F.A. Fasoyinu, Transactions of the American Foundrymen's Society V 102, Paper 94-110 (1994). ........................................... Understanding Inclusions in Aluminum Castings, M.J. Lessiter, Modern Casting (Jan. 1993). ...... Types and Formation Mechanisms of Casting Defects in Aluminium Alloy Castings, The, J.E.Eklund, J.J. Vuorinen, 60th World Foundry Congress, Netherlands (Sept. 1993). .................. Role of Inclusions on Pore Nucleation in Aluminum Casting Alloys, P. Mohanty, Light Metals Processing and Applications Conference (1993). ........................................................................... Origin and Identification of Inclusions in Foundry Alloys, The, C.E. Eckert, Jr., Proceedings of the 3rd AFS International Conference on Molten Aluminum Processing (Nov 1992). .......................... 1 TABLE OF CONTENTS Modifier-Antimony Interactions- The Problem, Mechanism and Solution, W. Wang, J.E. Gruzleski, Proceedings of the 3rd AFS International Conference on Molten Aluminum Processing (Nov 1992). ......................................................................................................................................................... Chemical Factors Affecting the Separation of Inclusions from Molten Aluminum, L.C.B. Martins, C.T. Keller, S. Shivkumar, Proceedings of the 3rd AFS International Conference on Molten Aluminum Processing (Nov 1992). .................................................................................................. Characterization of Oxide Sludge, Dross and Inclusions in Aluminum Melting and Holding Furnaces, P.N. Crepeau, B.L. Tiwari, K.M. Rahmoeller, Proceedings of the 3rd AFS International Conference on Molten Aluminum Processing (Nov 1992). ................................................................................. Molten Metal Filtration - Past, Present and Future Trends, D. Apelian, S. Shivkumar, Proceedings of the 2nd AFS International Conference on Molten Aluminum Processing, Orlando, FL (Nov 1989). ......................................................................................................................................................... Gas Porosity and Metal Cleanliness in Aluminum Casting Alloys, G. Laslaz, P. Laty, Transactions of the American Foundrymen’s Society V 99, Paper 91-40 (1991). ................................................ Mechanism of Corundum Formation and Prevention Techniques, D.V. Neff, R.G. Teller, Proceedings of the 2nd AFS International Conference on Molten Aluminum Processing, Orlando FL (Nov 1989). ...................................................................................................................................... Fractures – Positive Identification of Internal Defects in Aluminum Castings, R.H. Bruner, Transactions of the American Foundrymen's Society V 89, Paper 81-109 (1981). ........................ SECTION 2 – EFFECTS Effects and Consequences of Inclusions & Casting Process Interactions Direct Filtration of A356 Aluminum Alloy, T.Din, Transactions of the American Foundry Society, Vol. 111(2003). ............................................................................................................................... Effect of Gating System Design on the Quality of Aluminum Gravity Castings, E. Correa, R. Fuoco, Proceedings of the AFS Conference on Structural Aluminum Castings (2003). ........................... A Quality Low Pressure Aluminum Wheel, S.A. Levy, E.C. Burhop, 6th International AFS Conference on Molten Aluminum Processing, Orlando, FL, Nov. 11-13, 2001 (2001). ................ Microstructural Effects on High-Cycle Fatigue-Crack Initiation in A356.2 Casting Alloy, B. Zhang, Metallurgical and Materials Transactions (Oct. 1999).................................................................... Effects of Inclusions on the Tensile Properties of Al-7% Si-0.35% Mg (A356.2) Aluminum Casting Alloy, L. Liu, F.H. Samuel, Journal of Materials Science (May 1998). ........................................... Water Analog Study of Effects of Gating Designs on Inclusion Separation and Mold Filling Control, Transactions of the American Foundrymen’s Society, Vol.102, Paper 93-69 (1994).. .................. Important Minor Additions Affecting A356 Metal Quality, S. Levy, Proceedings of the 3rd International Conference on Molten Aluminum Processing (1992). .............................................. 2 TABLE OF CONTENTS Effect of Nonmetallic Inclusions and Test Temperature on the Fatigue Life of Cast C355, 354, and A206 Aluminum, The, C. Baker, ISTFA 1986: International Symposium for Testing and Failure Analysis (1986). ............................................................................................................................. Identifying Some Common Problems with Aluminum Castings, Transactions of the American Foundrymen’s Society, Vol. 81, Paper 73-34 (1973). .................................................................... Foundry Solidification Conditions and the Mechanical Properties of Cast Aluminum Alloys, J.T. Berry and M.S. Hundal, Unpublished AFS Research Report (1971) ............................................. SECTION 3 – EVALUATION Techniques to Evaluate Inclusions & Inclusion Effects Correlating Inclusion Sizes with Aluminum Casting, R. Gallo, Modern Casting (June 2004). ........ Ultrasound for On Line Inclusion Detection in Molten Aluminum, R. Gallo, H. Mountford, I. Sommerville, Proceedings from the AFS International Conference on Structural Aluminum Casting, Orlando, FL, November 2-4, 2003. .................................................................................................. Capability Study of the Improved PREFIL-Footprinter to Measure Liquid Aluminum Cleanliness and Comparison with Different Techniques, S. Simard, 6th International Conference on Molten Aluminum Processing (2001). ......................................................................................................... Evaluation of the Melt Cleanliness by K-mold, S. Kitaoka, Light Metals 2001: International Symposium on Light Metals (2001). ................................................................................................ SEM – Invaluable and Practical Tool for Casting Defect Analysis before a DoE, R. Gallo, Transactions of the American Foundry Society, V 109, Paper No 01-131 (2001). ......................... Inclusion Removal and Detection in Molten Aluminum, S. Makarov, D. Apelian, R. Ludwig, Transactions of the American Foundrymen's Society, Vol. 107, Paper No 99-150 (1999)............. Interaction of Initial Melt Cleanliness, Casting Process and Product Quality: Cleanliness Requirements Fit for a Specific Use, S. Dasgupta, 5th International Conference on Molten Aluminum Processing (1998). ......................................................................................................... Qualiflash as it Relates to Filtration and Degassing for Foundry and Extrusion Alloys, C. Evans, 5th International Conference on Molten Aluminum Processing (1998). ................................................ Assessment of Melt Cleanliness in A356.2 Aluminum Casting Alloy Using the Porous Disc Filtration Apparatus Technique Part I: Inclusion Measurements, L. Liu, F.H. Samuel, Journal of Materials Science (1997) ................................................................................................................................ Assessment of Melt Cleanliness in A356.2 Aluminum Casting Alloy Using the Porous Disc Filtration Apparatus Technique Part II: Inclusion Analysis, L. Liu, F.H. Samuel, Journal of Materials Science (1997). ............................................................................................................................................. PoDFA Measurements of Inclusions in 319.1 Alloy, H. de la Sablonniere, F. H. Samuel, Transactions of the American Foundrymen's Society, Vol. 104, Paper 96-21, (1996). .................. Quantified Reduced Pressure Test, W. LaOrchan, M. H. Mulazimoglu, X-G. Chen, J. E. Gruzleski, Transactions of the American Foundrymen's Society, V 103, Paper 95-28 (1995). ....................... 3 TABLE OF CONTENTS To Pour or Not to Pour - The Dilemma of Assessing Your Aluminum Melt's Cleanliness, M. J. Lessiter, W. M. Rasmussen, Modern Casting (1996). .................................................................... A Quantitative Assessment of the Cleaning Effect of Aluminum, etc. D. T. Hampton, Proceedings of the AFS 4th International Conference on Molten Aluminum Processing, Orlando, FL (Nov 12-14, 1995)................................................................................................................................................ A Shop Floor Technique for Quantitative Measurement of Molten Metal Cleanliness of Aluminium Alloys, P. G. Enright, I. R. Hughes, Proceedings of the AFS 4th International Conference on Molten Aluminum Processing, Orlando, FL (Nov 1995). ............................................................................. Foundry Methods for Assessing Melt Cleanliness, D. Groteke, 4th International Conference on Molten Aluminum Processing (1995). ............................................................................................. Qualiflash Apparatus for Testing the Inclusion Quality of Aluminum Alloy Baths, J. Roberge, 4th International Conference on Molten Aluminum Processing (1995). ................................................ Quantitative Measurement of Melt Cleanliness in Al-Si Casting Alloys, C. Chen, 4th International Conference on Molten Aluminum Processing (1995). ..................................................................... How Clean is the Metal You Cast? D. Apelian, Proceedings of the 3rd AFS International Conference on Molten Aluminum Processing (Nov 1992). ............................................................. Aluminum Cleanliness Monitoring, D. Doutre, B. Gariepy, J. P. Martin, G. Dube, Proceedings of 114th Annual Meeting, sponsored by TMS Light Metals Committee, New York, NY (Feb 24-28, 1985)................................................................................................................................................ Evaluation of Molten Metal Quality for Aluminum Alloys, S. A. Levy, Transactions of the American Foundrymen's Society, Vol. 93, Paper 85-151 (1985). ................................................................... Determining Abrasive Inclusions in Aluminum Alloys Castings, D. L. LaVelle Foundry (Oct 1969). ........................................................................................................................ SECTION 4 – REMOVAL Molten Metal Treatment: The Removal of Inclusions by Fluxing, Filtration & Flotation Improving the Reliability and Consistency of a Critical Casting Using Foam Filtration to Control the Mold Filling Process, B. Braun, Proceedings of the AFS Conference on Structural Aluminum Castings, Orlando, FL (Nov. 2-4, 2003). ......................................................................................... A Filter is More than Just a Filter, R. P. Pischel, Foundry M & T, Vol. 131, No. 4 (Apr. 2003). ..... Advantages of Corrugated Fibre Filters, No author given, Foundry Trade Journal. Vol. 177, No. 3602 (Apr. 2003). ............................................................................................................................. Filtering Basics - Who, What, Where, Why and How, K. Adams, E. J. Williams, S. Kannan, Modern Casting, V 92 N 3 (Mar 2002). ......................................................................................................... A Review of Melt Treatments in the Foundry, P. Fisher, P. Cooper, D. Boot, Proceedings of the 6th International Conference on Molten Aluminum Processing, Orlando, FL (Nov. 11-13, 2001). ....... 4 TABLE OF CONTENTS Advances in Filtration Technology for Permanent Mold Aluminum Castings, M. Stapleton, Proceedings of the 6th International Conference on Molten Aluminum Processing, Orlando, FL (Nov. 11-13, 2001). ................................................................................................................................... Development, Evaluation and Application of Granular and Powder Fluxes in Transfer Ladles, Crucible and Reverberatory Furnaces, R. Gallo, Proceedings of the 6th International Conference on Molten Aluminum Processing, Orlando, FL (Nov. 11-13, 2001)...................................................... Methodologies for Evaluating Filtering Efficiency in Aluminum Casting Processes, D. Neff, Proceedings of the 6th International Conference on Molten Aluminum Processing, Orlando, FL (Nov. 11-13, 2001). ................................................................................................................................... Properties of Fluxes Used in Molten Aluminum Processing, T. Utigard, Proceedings of the 6th International Conference on Molten Aluminum Processing, Orlando, FL (Nov. 11-13, 2001). ....... Mechanism of Filtration in Reduction of Casting Defects Due to Surface Turbulence During Mold Filling, Transactions of the American Foundrymen’s Society, Paper No. 97011 (1997). .............. “Principles of Non-Ferrous Metallurgy - Flux Treatment to Remove Oxide Contamination from Molten Aluminium Alloys,” J. Pulbrook, Die Casting Bulletin, N 76 (1997) ..................................... Optimization of Al Casting Productivity Using Foam Filter, P. Sandford, S.R. Sibley, Transactions of the American Foundrymen's Society, V 103, Paper 96-157 (1996). ............................................... A Comparison of Various Foundry Filters’ Effectiveness in Gravity Permanent Mold Castings of Aluminum, A. L. Matthews, F. A. Fasoyinu, J. L. Dion, M. Popescu, M. Sahoo, Proceedings of the AFS 4th International Conference on Molten Aluminum Processing, Orlando, FL (Nov 12-14, 1995). ......................................................................................................................................................... Continuous, “Re-Usable” Filtration Systems for Aluminum Foundries, D. Neff, Proceedings of the AFS 4th International Conference on Molten Aluminum Processing, Orlando, FL (Nov 12-14, 1995). ......................................................................................................................................................... Electromagnetic Filtration of Molten Aluminum Using an Induced-Current Separator, The, N. ElKaddah, A.D. Patel, T. T. Natarajan, JOM-Journal of the Minerals, Metals & Materials Society Vol. 47, No. 5, P 46-49 May 1995. ......................................................................................................... Recent Advances in Molten Aluminum Filtration Technology, J.R. Schmahl, L.S. Aubrey, L.C.B. Martins, Proceedings of the AFS 4th International Conference on Molten Aluminum Processing, Orlando, FL (Nov 12-14, 1995). ...................................................................................................... Direct Pouring of Aluminum Improves Yields and Quality, R. P. Pischel, Foundry M & T (June 1993)................................................................................................................................................ Benefits of Flux Injection Combined with Rotor Dispersion for Producing Clean Aluminum Casting Alloys, D. Neff, Proceedings of the 3rd AFS International Conference on Molten Aluminum Processing (Nov 1992). ................................................................................................................... Practical Sand Foundry Experience Using In-Mold Filters for the Production of Aluminum Flat Castings, F. Chiesa, Proceedings of the 3rd AFS International Conference on Molten Aluminum Processing (Nov 1992). ................................................................................................................... Flux Practice in Aluminum Melting, B.P. Cochran, M.L. Fenyes, J. L. Jeanneret, R.P. Mulac, P. N. Crepeau, Transactions of the American Foundrymen's Society, V 100, Paper 92-88 (1992). ...... 5 TABLE OF CONTENTS Melt Quality Upfront, L.M. Fenyes, C. Nelson, G. Reinemann, Proceedings of the 3rd AFS International Conference on Molten Aluminum Processing (Nov 1992). ........................................ Solid Aluminum Fluxing Issues, P.N. Crepeau, B.P. Cochran, R.P. Mulac, Modern Casting V 82 N 8 (Aug 1992). ................................................................................................................................... Control of Inclusions in Sand Casting, The, P.D. Webster, Foundry Trade Journal, V 165, N 3438, (Aug 9, 1991). .................................................................................................................................. Filtration of Liquid Metals, H. Clark, Foundryman, V 84, N 9 (Oct 1991). ....................................... Road to Cleaner Aluminum Melts, The, J. Cleave, Foundry Trade Journal, V 165, N 3438 (Aug 9, 1991)................................................................................................................................................ Filtration Techniques for Aluminum Castings, H. Devaux, D. Hiebel, S. Jocob, M. Richard, Proceedings of the 2nd AFS International Conference on Molten Aluminum Processing, Orlando, FL (Nov 1989). ................................................................................................................................ Current Status of In-Furnace Filtration Systems, D. Groteke, Proceedings of the 2nd AFS International Conference on Molten Aluminum Processing, Orlando, FL (Nov 1989). ................... Design and Development of Fluxing Agents for Aluminum Foundry Alloys, M. H. Hogan, Proceedings of the 2nd AFS International Conference on Molten Aluminum Processing, Orlando, FL, (Nov 1989). ...................................................................................................................................... Inclusion Removal by Flotation and Stirring, L.C.B. Martins, G.K. Sigworth, Proceedings of the 2nd International Conference on Molten Aluminum Processing, Orlando, FL (Nov 1989). ................... Metal Filtration: A Critical Review and Update, D. Apelian, Electric Furnace Proceedings, Iron and Steel Society of AIME, V 46 (Dec 6-9, 1988). ................................................................................. Molten Metal Filtration Improves Casting Quality and Machinability, No Author Listed, Foundry Management & Technology, V 116, N 10 (Oct 1988). .................................................................... An Overview of the Need for Melt Cleanliness, J. Jorstad, Proceedings of the 1st International AFS/CMI Conference on Molten Aluminum Processing, City of Industry, CA (Feb.17-18, 1986). . Point of Pour Filtration Systems for Aluminum Alloys, D. Groteke, Proceedings of the 1st International AFS/CMI Conference on Molten Aluminum Processing, City of Industry, CA (Feb. 1718, 1986).......................................................................................................................................... Controlling Aluminum-Alloy Melts for DieCasting, A. Kaye, Foundry Trade Journal, V 154, N 3263 (May 1983). ..................................................................................................................................... Reduction of Inclusions in Aluminum by Filtration, The, D. E. Groteke, Modern Casting (April 1983) ......................................................................................................................................................... Experience with Ceramic Foam Filtration of Aluminum Castings, R. Mollard and N. Davidson, Transactions of the American Foundrymen’s Society, Vol. 80, Paper No. 139, pp. 595-600 (1980). ......................................................................................................................................................... Influence of Gas Injection on Metal Quality in an Aluminum Channel Induction Furnace, L. Smith, British Foundryman (Oct 1976). ...................................................................................................... Removal of Non-Metallic Inclusions and their Assessment of A1-alloy Melts, D. Hedjazi, G. Bennett, V. Kondic, British Foundrymen (Dec. 1975). ................................................................................... 6