50 HP York Shipley Boiler Specs | Model YSG 542-SPH-50-S150

advertisement

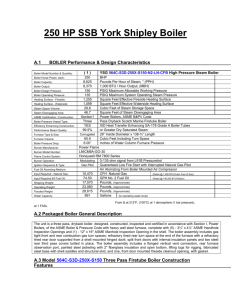

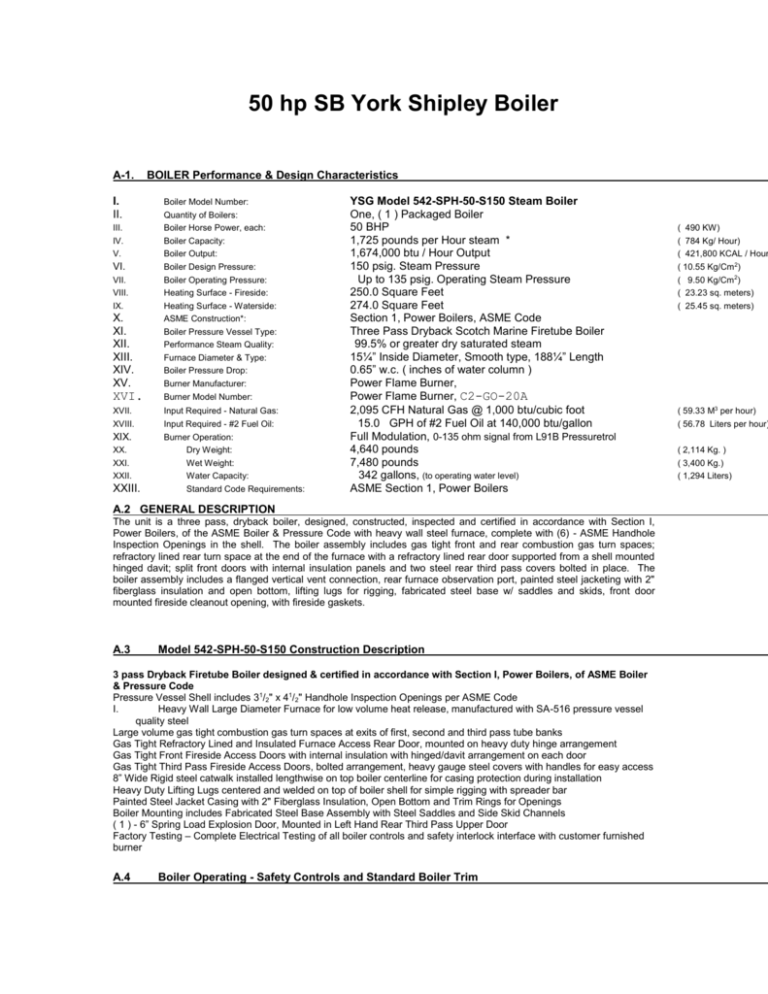

50 hp SB York Shipley Boiler A-1. I. II. III. IV. V. VI. VII. VIII. IX. X. XI. XII. XIII. XIV. XV. BOILER Performance & Design Characteristics Boiler Model Number: Quantity of Boilers: Boiler Horse Power, each: Boiler Capacity: Boiler Output: Boiler Design Pressure: Boiler Operating Pressure: Heating Surface - Fireside: Heating Surface - Waterside: ASME Construction*: Boiler Pressure Vessel Type: Performance Steam Quality: Furnace Diameter & Type: Boiler Pressure Drop: Burner Manufacturer: XVI. Burner Model Number: XVII. XVIII. Input Required - Natural Gas: Input Required - #2 Fuel Oil: Burner Operation: Dry Weight: Wet Weight: Water Capacity: Standard Code Requirements: XIX. XX. XXI. XXII. XXIII. YSG Model 542-SPH-50-S150 Steam Boiler One, ( 1 ) Packaged Boiler 50 BHP 1,725 pounds per Hour steam * 1,674,000 btu / Hour Output 150 psig. Steam Pressure Up to 135 psig. Operating Steam Pressure 250.0 Square Feet 274.0 Square Feet Section 1, Power Boilers, ASME Code Three Pass Dryback Scotch Marine Firetube Boiler 99.5% or greater dry saturated steam 15¼” Inside Diameter, Smooth type, 188¼” Length 0.65” w.c. ( inches of water column ) Power Flame Burner, Power Flame Burner, C2-GO-20A 2,095 CFH Natural Gas @ 1,000 btu/cubic foot 15.0 GPH of #2 Fuel Oil at 140,000 btu/gallon Full Modulation, 0-135 ohm signal from L91B Pressuretrol 4,640 pounds 7,480 pounds 342 gallons, (to operating water level) ASME Section 1, Power Boilers A.2 GENERAL DESCRIPTION The unit is a three pass, dryback boiler, designed, constructed, inspected and certified in accordance with Section I, Power Boilers, of the ASME Boiler & Pressure Code with heavy wall steel furnace, complete with (6) - ASME Handhole Inspection Openings in the shell. The boiler assembly includes gas tight front and rear combustion gas turn spaces; refractory lined rear turn space at the end of the furnace with a refractory lined rear door supported from a shell mounted hinged davit; split front doors with internal insulation panels and two steel rear third pass covers bolted in place. The boiler assembly includes a flanged vertical vent connection, rear furnace observation port, painted steel jacketing with 2" fiberglass insulation and open bottom, lifting lugs for rigging, fabricated steel base w/ saddles and skids, front door mounted fireside cleanout opening, with fireside gaskets. A.3 Model 542-SPH-50-S150 Construction Description 3 pass Dryback Firetube Boiler designed & certified in accordance with Section I, Power Boilers, of ASME Boiler & Pressure Code Pressure Vessel Shell includes 31/2" x 41/2" Handhole Inspection Openings per ASME Code I. Heavy Wall Large Diameter Furnace for low volume heat release, manufactured with SA-516 pressure vessel quality steel Large volume gas tight combustion gas turn spaces at exits of first, second and third pass tube banks Gas Tight Refractory Lined and Insulated Furnace Access Rear Door, mounted on heavy duty hinge arrangement Gas Tight Front Fireside Access Doors with internal insulation with hinged/davit arrangement on each door Gas Tight Third Pass Fireside Access Doors, bolted arrangement, heavy gauge steel covers with handles for easy access 8” Wide Rigid steel catwalk installed lengthwise on top boiler centerline for casing protection during installation Heavy Duty Lifting Lugs centered and welded on top of boiler shell for simple rigging with spreader bar Painted Steel Jacket Casing with 2" Fiberglass Insulation, Open Bottom and Trim Rings for Openings Boiler Mounting includes Fabricated Steel Base Assembly with Steel Saddles and Side Skid Channels ( 1 ) - 6” Spring Load Explosion Door, Mounted in Left Hand Rear Third Pass Upper Door Factory Testing – Complete Electrical Testing of all boiler controls and safety interlock interface with customer furnished burner A.4 Boiler Operating - Safety Controls and Standard Boiler Trim ( 490 KW) ( 784 Kg/ Hour) ( 421,800 KCAL / Hour ( 10.55 Kg/Cm2) ( 9.50 Kg/Cm2) ( 23.23 sq. meters) ( 25.45 sq. meters) ( 59.33 M3 per hour) ( 56.78 Liters per hour) ( 2,114 Kg. ) ( 3,400 Kg.) ( 1,294 Liters) I. II. III. IV. V. VI. VII. VIII. IX. X. XI. XII. XIII. Primary Low Water Cutoff Control: ( 1 ) - MM #157S Float Type Control, Automatic Reset Secondary Low Water Cutoff Control: relay switch High Water Alarm: for pricing Feedwater Control & Operation: Primary LWCO Water Level Gauge: Piping Water Level Gauge Valves: Checks Tri-Cock Valves: Pressure Control: High Limit - Manual Reset: Range Pressure Control: Operating Limit Range Pressure Control: Low Fire Hold Range Pressure Control: Modulating Control Range Steam Pressure Gauge: snubber and shutoff valve ASME Safety / Relief Valves: (Size as Required) A.5 ( 1 ) - Not Included, available as option, see Section B ( 1 ) - On/Off Pump Operation from Control Switch in ( 1 ) - Mounted on Primary LWCO Water Column ( 1 ) - Set, ½” npt x 150 psig., with ASME Safety Ball ( 3 ) - ½” x 250# - Mounted on Primary LWCO ( 1 ) - Honeywell # L404C Pressuretrol, 10 to 150 psig. ( 1 ) - Honeywell # L404A Pressuretrol, 10 to 150 psig. ( 1 ) - Honeywell # L604A Pressuretrol, 10 to 150 psig. ( 1 ) - Honeywell # L91B Pressuretrol, 10 to 150 psig. ( 1 ) - 6" Diameter, 0 - 300 psig. Range, with pressure ( 1 ) - ASME Certified Safety Valve, set @ 150 psig. Boiler Principal Piping Connections and Sizes I. Main Steam Supply Outlet: coupling with Internal Steam Dry-Pan II. Surface Blowoff Connection: with internal skimmer III. LWCO Trim Control Connection/s: threaded coupling IV. Feedwater Inlet Connection: threaded coupling V. Blowdown Connection/s: threaded coupling VI. Safety Valve Connection/s: threaded couplings VII. Vertical Stack Flange Connection: flange for 2000 lb. load A.6 ( 1 ) - MM#750B Probe type Control with manual reset ( 1 ) - 2" NPT x 3000 psig. forged steel threaded ( 1 ) - 1¼” Schedule 80 - SA-106 Steel Pipe Nipple ( 1 ) - 1" NPT x 3000 psig. SA-105 forged steel ( 1 ) - 1¼” NPT x 3000 psig. SA-105 forged steel ( 1 ) - 1¼” NPT x 3000 psig. SA-105 forged steel ( 1 ) - 1¼ NPT x 3000 psig. SA-105 forged steel ( 1 ) - 8” ID, with 2” wide structural steel mounting Boiler Mounted Valves, Equipment and Optional Accessories I. Flue Gas Outlet Thermometer: Thermometer, Installed II. Water Gauge Blowdown Valve: valve on water column III. Primary LWCO Blowdown Valve: ASME Certified * IV. Bottom Blowdown Valves: Pre-Piped & ASME Certified * V. Feedwater Stop & Check Valves Pre-Piped & ASME Certified * VI. Surface Blowdown Valve: Valve, Pre-Piped & ASME Certified * VII. Modulating Feedwater Valve Assembly: Section B - OPTIONS) VIII. Main Steam Non-Return Stop-Check Valve: Section B - OPTIONS) IX. Main Steam Outside Screw & Yoke Gate Valve: Section B - OPTIONS) ( 1 ) - 3" Diameter, 200oF - 1000oF. Range ( 1 ) - ¼” x 150# built-in valve on bottom water gauge ( 1 ) - 1” x 150 psig. bronze ball valve, Pre-Piped & ( 1 ) - Set, 1¼” x 150 psig. Tandem Blowdown Valves, ( 1 ) - Set, 1” x 150 psig. Feed, Stop & Check Valves, ( 1 ) - ½” x 250 psig. Manual Surface Blowdown Not Included, Available as Optional Equipment, (See Not Included, Available as Optional Equipment, (See Not Included, Available as Optional Equipment, (See * Mounted, Piped & Certified in accordance with ASME Section1, B31.1 & CSD-1 Dimensions: Weight: Approx. 5,000 lbs Approx. 12’-4” L. x 5’-0” W. x 5’-2” H.