AB-502-Heating-Plant-Card

advertisement

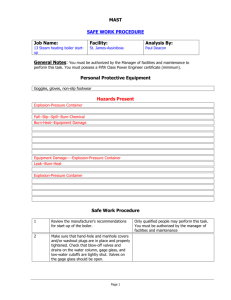

GUIDELINES FOR CARE AND OPERATION OF HOT WATER HEATING BOILERS The owner is responsible for the proper care and safe operation of a Heating Plant in accordance with Section 4 of the Power Engineers Regulation. The following instructions should be carried out by a responsible person who has the necessary skill and knowledge. 1. DAILY (a) Observe operating pressures, temperatures and general conditions. Determine the cause of any unusual noises or conditions and make necessary corrections. (b) Arrange for repairs to be made at the first indication of defects, leakage or malfunction at safety relief valves, safety devices or operating controls. (c) Keep the boiler room clean. Observe precautionary measures for fire safety. (d) Ensure that there is adequate combustion air in the boiler room. (e) Maintain a Boiler Room Log and record the various routines and tests that are performed. 2. WEEKLY (a) Observe conditions of flame and correct if flame is smoky or if burner starts with a puff. (b) Observe operation of circulating pump(s). 3. MONTHLY (a) Operate the safety relief valves manually by means of the try lever when boiler pressure is more than 75% of valve set pressure. (b) Test flame detection devices. (c) Test low-water fuel cut-off if piping arrangement permits without draining considerable water from boiler. (d) Record results. 4. ANNUALLY Arrange for a reliable servicing company to: (a) during the off-season, completely check the condition of the boiler, low-water fuel cut-off, feedwater regulator, combustion controls, safety devices, and (b) during the heating season, check that the operational controls and safety devices are functioning properly. NOTE: For more detailed information reference should be made to the ASME Boiler and Pressure Vessel Code, Section VI, "Recommended Rules for Care and Operation of Heating Boilers." AB-502 (2005-11) GUIDELINES FOR CARE AND OPERATION OF STEAM HEATING BOILERS The owner is responsible for the proper care and safe operation of a Heating Plant in accordance with Section 4 of the Power Engineers Regulation. The following instructions should be carried out by a responsible person who has the necessary skill and knowledge. 1. DAILY (a) Observe operating pressures, water level, and general conditions. Determine cause of any unusual noises or conditions and make necessary corrections. (b) Arrange for repairs to be made at the first indication of defects, leakage or malfunction at safety valves, safety devices, or operating controls. (c) Keep the boiler room clean. Observe precautionary measures for fire safety. (e) Ensure that there is adequate combustion air in the boiler room. (f) Maintain a Boiler Room Log and record the various routines and tests that are performed. 2. WEEKLY (a) Test low-water fuel cut-off. (b) Test water column or gauge glass. (c) Observe condition of flame and correct if flame is smoky or if burner starts with a puff. (d) Blowdown boiler if considerable make-up is used. 3. MONTHLY (a) Operate the safety valves manually by means of the try lever when boiler pressure is more than 75% of valve set pressure. (b) Test flame detection devices. (c) Blowdown sludge from the boiler as required. (d) Record results. 4. ANNUALLY Arrange for a reliable servicing company to: (a) during the off-season, completely check the condition of the boiler, low-water fuel cut-off, combustion controls, safety devices, and (b) during the heating season, check that the operational controls and safety devices are functioning properly. NOTE: For more detailed information reference should be made to the ASME Boiler and Pressure Vessel Code, Section VI, "Recommended Rules for Care and Operation of Heating Boilers." AB-502 (2005-11)