Technology Upgradation of SMEs in India Garment Sector

advertisement

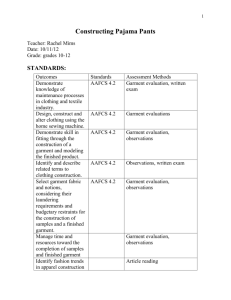

TECHNOLOGY UPGRADATION OF SMEs IN INDIAN GARMENT SECTOR P.B. JHALA Senior Deputy Director Ahmedabad Textile Industry's Research Association Ahmedabad-380 015, India. 1.0 INTRODUCTION: The Indian garment industry plays a key role in the country's economy. It provides employment to more than 3 million people and constitutes 13% of the foreign exchange earnings of the country. Ranking within the top ten world clothing exporters as shown in Fig.1, the export of ready-made garments from India amounted to 1504 million pieces valued at US $ 5765 million during the year 2000. The exports trend in the last decade is shown in Table 1. India has set an export target of US $ 25 bn for clothing by 2010. Out of the total exports in value terms, 35.8% go to the USA, 33.1% to Europe particularly France, Germany, 4.5% to Canada and the rest 26.6% to non-quota countries, around the world particularly to United Arab Emirates, CIS and Japan. The industry has been catering only to lower end of mainly cotton global market with unit realisation far below the levels of its competitors abroad. The industry is primarily consisting of SMEs with traditional technology and inadequate quality systems. It requires cost-effective technology upgradation in presewing, sewing and post-sewing processes to increase productivity, reduce costs, adapt quickly to the demand cycle and improve quality. The industry is in the process of modernisation to face the global challenges in the export-front and stiff competition in the local market due to liberalised imports. The government is also providing support to the industry in various forms in the above pursuit. (1) 2.0 INDUSTRY PROFILE: The Indian garment industry is a labour intensive industry with about 58,000 units spread over the entire sub-continent (Table 2). The industry has two major sectors, the knitted sector around 10,000 units, the woven sector around 48,000 units. The average size of unit is small and not exceeding 15 to 20 machines. The pattern of production of garment industry is weighted in favour of ladies garments. This is only to be expected since these garments land themselves to all kinds of fashion and embelishments adding value to the garment. As far as western style garments are concerned, the pattern of production is estimated as men's wear 25%, ladies wear 60% and children wear 15%. In the case of ethnic wear the pattern is weighted heavily towards ladies' wear 80% (which includes girls wear) and 20% for mens' wear (which includes boys wear). The strengths of Indian garment industry are in flexibility in manufacturing, low labour cost, strong fabric base and ethnic value addition. The weaknesses lie in low productivity, inconsistent quality, limited efforts of value addition, high degree of fragmentation, low level of textile/apparel linkage and inadequate support of human resource. 3.0 TECHNOLOGY STATUS: The Indian apparel industry exhibits varying levels of technology ranging from traditional to most modern and this has impacted the overall growth and productivity of the sector. The recent national study on technological upgradation needs of Ready-made Garment (RMG) Industry conducted by Garment Manufacturing Technology (GMT) Department of National Institute of Fashion Technology (NIFT) has brought out the technology status of the industry. This has been given in Fig.2. In export sector only 21% manufacturers use modern technology even by Indian Standards and 70% (2) between modern technology by Indian Standards and primitive technology No company has overall rating of world class technology. However, 17% owners perceive of world class plant. In apparel manufacturing for domestic sector, the situation is not different. The manufacturers tend to over estimate the technology level of their plant. Only 9% factories are modern by Indian Standards but 33% manufacturers feel that they have modern plant by Indian Standards. Sixteen percent owners feel that they have a world class plant but actually none of them have reached that stage. This shows that Indian garment industry lags behind in modernisation. 4.0 PRODUCTIVITY AND QUALITY: The productivity in the Indian garment industry is low when compared with its major competitors. The Kurt Salmon Associates (KSA) study on manufacturing cost comparison has also given productivity rating for apparel manufacturing countries. India is rated at 50% whereas its neighbours like Sri Lanka and Thailand are rated at 65%. Countries like USA and Germany are rated at 100%. Apparel productivity research by GMT Department NIFT, also reveals labour productivity improvement potential in sewing room upto 100% in case of the Indian apparel industry as shown in Table 3. Apart from the quality of fabric, the manufacturing processes in the apparel industry play an important role to achieve the level of quality standards. This is also evident from one of the studies conducted by the GMT Department at NIFT which is based on a comparative analysis of industry norms in the industrialized countries and Indian Apparel industry as shown in Table 4. (3) 5.0 STRATEGIES FOR TECHNOLOGY UPGRADATION: Indian apparel manufacturers have been engaged in the process of technology upgradation in a gradual manner. The technology upgradation plans for each establishment need to be drawn by individual companies as a part of overall organisational strategies. A piecemeal approach can be harmful. Steps involved in developing technology strategy include knowing the present status, understanding buyer needs, knowing technological options available, where to start, setting of standards and review of results. On the basis of current status of technology level in factories and taking in account the views expressed by representatives of international buyers, broad guidelines for the technology mix for different product specialisation and price points have been developed by GMT Department, NIFT which are given in Table 5 and Table 6. Machine mix for sewing, pre-sewing and post-sewing, including software appications have been recommended for factories aiming at low, medium and high price segments of the international market. Buyers may not have specific technology requirement in all micro areas but there might be minimum expectations which a plant of today must have to qualify to be a supplier. These equipments are termed as `order qualifier'. The equipments which shall further improve quality and technology status of the factory but are not must are termed as `desirable'. Certain machines are shown as `optional'. These will be added depending on product needs. It may be important to note before referring to the guidelines on up-gradation for various product specialisation, that highly specialised automated technological solutions are available for many functional areas. However, these equipments are not mentioned in the guidelines as these technologies can only be justified with economics of scale. Manufcturers are advised to carry out a detailed payback analysis before taking decisions on these solutions. The guidelines for upgradation does not include `washing' area. Specialised garment washes have gained popularity in international market. Depending on (4) market orientation and product specialisation washing technology will have to be selected. Need for washing machines can vary a great deal, hence washing equipment will have to be added on specific need basis. 6.0 CONCLUSION: The need for technology upgradation of the garment industry is extremely urgent on account of quality as well as productivity. Average Indian garment manufacturer has vast potential to improve quality as well as productivity. Installations of sophisticated machines and better skills would enable to gain a competitive edge in the global trade. If India has to globalise its garment trade, the industry will have to work the way the world does. 7.0 ACKNOWLEDGEMENT: The author is grateful to Dr. M.M. Gharia, Director, ATIRA, for his kind permission to present this paper at this Interntional Seminar. Thanks are also due to Prof. Rajesh Bheda and Prof. Pavan Godiawala, NIFT for useful discussions. The financial support provided by the APCTT and MOST for presentation of this paper at the above Seminar is gratefully acknowledged. 8.0 REFERENCES: 1. Technological Upgradation Needs of Ready Made Garment Industry, Research Project Report, NIFT, New Delhi, 1999. 2. National Conference on Management of Technology in Apparel Industry, NIFT and SIDBI, Chennai, July 1999. 3. Technology and Strategies of Garment Industry in Changing Scenario, Rajesh Bheda & S.K. Bhardwaj, 55th All India Textile Conference, Emerging Trends on Textile Horizen, Mumbai, December 1999. 4. Have Quota Restrictions Increased Indian Garment Exports, M.K. Panthakl, Clothesline, April 2001. (5) TABLE 1 : EXPORTS OF READY-MADE GARMENT FROM INDIA Year Knitted Garments Woven Garments Total Exports mn. pcs mn. $ mn. pcs mn. $ mn. pcs mn. $ 1991 249.96 542.77 414.82 1858.87 664.78 2401.64 1992 313.00 751.00 445.50 2132.10 758.50 2883.10 1993 433.20 1052.70 472.00 2413.90 905.20 3466.60 1994 426.00 1123.60 570.00 3298.30 996.00 4421.90 1995 436.70 1155.10 623.50 3318.40 1060.20 4473.50 1996 540.20 1469.70 644.50 3322.40 1184.70 4792.10 1997 632.40 1599.70 667.00 3264.00 1301.40 4863.70 1998 682.00 1627.20 655.70 3421.50 1337.70 5048.70 1999 758.40 1885.20 646.00 3488.00 1404.40 5323.20 2000 827.70 2043.10 677.10 3722.00 1504.80 5765.10 Source: Apparel Export Promotion Council (AEPC). TABLE 2 : STATUS OF INDIAN GARMENT INDUSTRY Sector Number of Units Number of Installed Machines Ancillary Machines Knitted 10,214 1,53,212 - Investment US $ Million Total Production US $ Million (Million Pieces) 214 - Woven 47,852 7,17,778 Total 1,751 - Total 58,066 8,70,990 2,87,111 11,58,101 1,965 21,172 (5,528) Source: Clothing Manufacturers Association of India (CMAI), Data : Dec. 1999. (6) TABLE 3 : PRODUCTIVITY RATES IN SHIRTS MANUFACTURING IN INDIA AND ASIA, 1996 Productivity Machine Productivity: Average Minimum Maximum Total Labour Productivity: Average Minimum Maximum Machine Productivity Technology: Average Minimum Maximum Source: Asia Including India at India Rest of Asia 13.17 5.09 25.87 9.99 5.09 22.22 17.47 5.53 25.87 9.71 4.07 16.64 7.88 4.07 15.87 12.18 4.78 16.64 10.50 4.58 11.03 8.07 4.58 17.05 13.84 4.76 21.03 Base GMT Department NIFT. TABLE 4 : COMPARATIVE ANALYSIS IndustrialisedCountry India o 2% Seconds o 10% Seconds o 5-8% repairs o 50% + repairs o 30% excellence rating of financial o product. o Source: GMT Department NIFT. (7) 5-10% excellence rating. High quality related costs (examiners, Thread trimmers, repair hands). TABLE 5 : TECHNOLOGY MIX GUIDELINES FOR SHIRT MANUFACTURING MACHINE TYPE SOFTWARE APPLICATION: Fabric Design Fashion Design Production planning & scheduling Pattern making, grading and marker making Product Data Management Labour costing Cut Plan and Lay Plans Bundling and Ticketing FABRIC INSPECTION: Fabric inspection machine SPREADING: Spreading machine CUTTING: Straight knife machine Cloth drill and Notcher Pin table and laser light End Cutter Die Clicker and Band knife Fusing Machine LOW PRICE MEDIUM PRICE HIGH PRICE * * * * * * ** * * * ** * * * * - * * * * * ** ** * * ** ** * ** ** ** * ** * ** ** * ** ** Flat Bed ** ** ** Continuous ** ** ** Continuous ** ** ** ** ** ** * * * ** ** ** ** ** ** ** ** ** ** * ** * * * ** ** ** ** ** ** ** ** ** ** ** - * - ** * SEWING: High speed 1 needle lock stitch Lock stitch button sewing & button hole SNLS Needle feed Pocket creasing machine Collar contour trimmer 4 Needle chain stitch (placket making) Feed off the arm Collar & cuff turning and blocking SNLS with edge cutter Programmable lock stitch Top Feed lock stitch Placket creasing SNLS with UTT Double Needle lock stitch with split needle bar. Profile stitch with edge cutter Sequential button hole (contd….9) (8) TABLE 5 : TECHNOLOGY MIX GUIDELINES FOR SHIRT MANUFACTURING (contd.) MACHINE TYPE LOW PRICE MEDIUM PRICE HIGH PRICE ** Gun ** ** * ** * ** Work station ** ** * * ** * ** Work station ** ** ** * ** * FINISHING: Stain removing machine Steam iron with vacuum board Shirt folding table Body press/Form finisher Thread trimming machine Thread suction machine** Dry cleaning machine (Perc) * Desirable ** Order qualifier Source: GMT Department, NIFT. (9) TABLE 6 : TECHNOLOGY MIX GUIDELINES FOR FASHION GARMENT MANUFACTURING MACHINE TYPE SOFTWARE APPLICATION: Fabric Design Fashion Design Production planning & scheduling Pattern making, grading and marker making Product Data Management Labour costing Cut Plan and Lay Plans Bundling and Ticketing FABRIC INSPECTION: Fabric inspection machine SPREADING: Spreading machine CUTTING: Straight knife machine Cloth drill and Notcher End cutter Band knife and Die clicker Fusing Machine Strip cutting machine SEWING: High speed 1 needle lock stitch Blind stitch LS with top and bottom feed Multy needle chain stitch Multi head embroidery (optional) Five thread safety stitch with top feed Three thread over lock Bar tack Lock stitch with UTT and Auto back tack Four needle waist band elastic machine Zig-Zag Lock Stitch Lock stitch with edge cutter Five thread safety stitch with top and bottom feed LOW PRICE MEDIUM PRICE HIGH PRICE * * * * ** ** * ** ** ** ** ** * * - ** ** * - ** ** ** ** * ** ** * * ** ** * * * ** Flat Bed ** ** * * ** ** Continuous ** ** * * ** ** Continuous ** ** * * ** ** * ** ** * ** ** ** ** ** ** ** ** ** * ** ** ** ** ** ** ** ** ** ** ** - ** ** ** ** ** ** (contd….11) (10) TABLE 6 : TECHNOLOGY MIX GUIDELINES FOR FASHION GARMENT MANUFACTURING (contd.) MACHINE TYPE FINISHING: Stain removing machine Steam iron with vacuum/blowing board (flat & utility) Form finisher/blowing Thread trimming machine Thread suction machine** Dry cleaning machine (Perc) * LOW PRICE MEDIUM PRICE HIGH PRICE ** Gun ** ** Work station ** ** Work station ** * * ** * * * ** ** ** * ** ** Desirable ** Order qualifier Source: GMT Department, NIFT. ….. (11) GARMENTPAPER/PBJ/29.8.2001