Understanding the Global Apparel Manufacturing Process PPT

advertisement

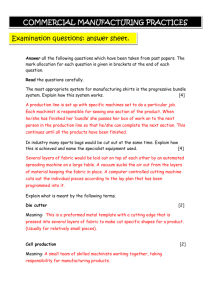

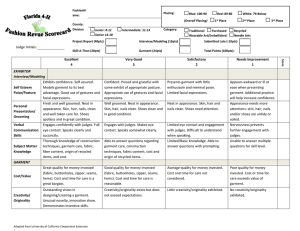

Understanding the Global Apparel Manufacturing Process 2.02 How our clothing is created… From Design to Reality… Once a prototype, or example of the product has been created, then the manufacturing process begins… Image Source: http://www.sdfltd.com/wp-content/uploads/2013/07/clothing_manufacturer.jpg Developing a Production Pattern There are four steps to the process of creating a pattern for a manufactured apparel product: 1. 2. 3. 4. Grading Marking Spreading Cutting ImageSource: http://www.artec3d.com/upload/iblock/ee2/Pattern-production.jpg Creating Different Sizes Most apparel products come in various sizes. Patterns have to be created for each size. This process is called grading. Image Source: http://www.patternsandgrading.com/sitebuilder/images/grading_only-540x355-540x351.png How is Grading Done Grading can be done by: a CAD (Computer Aided Design) software program or By hand on paper Developing a Marker Marking is the process that uses a computer or paper to create an outline of the shape of the pattern piece . The markers are then placed on the fabric in a way ensure the least amount of wasted fabric possible. Image Source: http://3.bp.blogspot.com/-LqjRC1l3VA8/Td5Mxl9GpGI/AAAAAAAAG0E/eX_rqraOjss/s1600/LADIES+NIGHT+DRESS-NIGHTYMARKER+PLANNING.bmp Spreading the Fabric Spreaders are machines used to place multiple layers of fabric so they can be cut into pieces ready for assembly. Cutting It All Out… The cutting process usually involves one of two primary types of machines: 1. Electric Cutting Knife 2. Laser Cutting Machine Electric Knife Machine Computerized Laser Cutter Assembling the Product Apparel assembly usually involves one of four basic methods: 1. 2. 3. 4. Tailoring/Whole Garment Progressive Bundle/Piecework Unit Production Modular Manufacturing Tailoring/Whole Garment One person creates the design, pattern and assembles the garment from start to finish. Image Source:http://images.clickliverpool.com/admin/article/articleimages/1263472034-tailor.jpg Progressive Bundle/Piecework Each operator does different parts of the assembly process Image Source: http://morethanshipping.com/wp-content/uploads/2011/08/BANGLADESH.bmp Unit Production This system involves transporting all of the parts of the product together in a carrier through the entire assembly process. Image Source: http://img.diytrade.com/cdimg/437786/4273562/0/11894040 64/Euratex_Unit_Production_System.jpg Modular Production Multiple operators work together as a team to create the product with each individual performing multiple steps. Standards of Quality Control When measuring the quality of a finished product, there are two different types of quality to consider • • Design Quality Manufacturing Quality Design Quality Design quality takes into consideration the features that are part of the design of a garment. Certain sewing techniques and seam finishes are used on higher quality garments that would not be seen on garments of lesser quality – ie. bound seams, top stitching etc. Manufacturing Quality Manufacturing quality considers the care with which a garment has been created. Workers in this area of inspection would look for: 1. color defects 2. construction defects 3. sizing defects