Cultural Resource areas of Concern for Burn

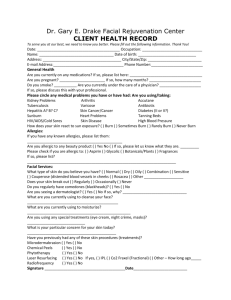

advertisement

Including a Cultural Resource advisor in the burn planning process can help to achieve these objectives. For example a cooler burn on a site may be all that is necessary to protect that site. For every burn the questions we ask will be: How can we achieve our objectives? (From a land management perspective) What kind of fire effects can we expect? (From a compliance perspective) Our involvement will vary by park area, and be plan-dependent, with differing levels of operational involvement at each stage of the burn planning and implementation. Delineating boundary lines Providing general information about the types of resources. Objectives based on know or expected resources. These objectives are general for known sites- we expect to discover previously unknown sites in the process and thus need some operational flexibility from the burn plan and the burn crews. In exchange, we are looking for a balanced, flexible approach-not 100% inventory coverage. We need to know what kind of cultural resources to expect through our background work. Objectives for all resources: Protect resources from ground disturbance Handlines Reduce direct fire impacts Heat (burning, spalling, cracking, potlidding, discoloration, smudging) C14, magnetic contamination Reduce indirect impacts Erosion Collapsing snags Objectives for archeological resources: Reduce fuels next or near sensitive resources such as pictograph panels or bedrock mortars Maintain fuel loads that will not create intense artifact-altering fires Objectives for historic structures: Reduce fuels adjacent to structures (maintain defensible space) Restore and maintain historic landscapes Assess and upgrade structural fire protection facilities and response plans at National Historic Landmarks and other National Register properties Objectives for Traditional Cultural Places: Maintain traditional landscape characteristics at ceremonial, spiritual and historic places Traditionally gathered plant Vegetation patterning Openness View-shed Where fire is a traditional management tool, incorporate traditional burning methods and use native people to conduct burns Information that Cultural Resources needs in a burn plan: Who will be conducting the burn? This includes the POC and how many crews will be involved. What will take place? What type of burn is this? What type of disturbance do we expect to see? (staging camp, hand line, etc.) What kind of intensity do we expect to see? Where will the burn take place? How definite (precise) are the area boundaries? Can we define burn area boundaries based on logical resource-based criteria? Can we reduce fuel loads on complete sites in cases where burn area boundaries bisect sites? When will the burn take place? This will have to do with your priority areas. CR may have requests for a burn to protect a particular resource. How will the burn take place? This includes the operational aspect of the plan. For example, we may want to see manual fuel reduction near sites or avoidance when using handlines. How will the fire be contained? Cultural Resources will provide you with timely information about existing sites in the area, our best estimate about how many sites we expect to find, and our best suggestions for avoiding or mitigating known sites so that you can do your job. There is not a lot of information yet available on the effects of fire on sites, features and artifacts. That information is on its way and as it becomes available, we will pass it along to you for incorporation into the burn plans. Below is a summary of what the current literature suggests. Thresholds for lithic artifacts (Excerpted from Deal, 2001) Lithics (stone tools) inform on date, economic trade, food types and cultural affiliation (p.1). Fire processes impact lithics at all stages. Thinning may displace or break artifacts. During a burn, uneven heating may crack, spall, pit, or potlid artifacts from thermal shock while application of foam or water may cause spalling or fracture by cooling rapidly (p. 2). Direct exposure to fire and smoke may discolor, or vitrify artifacts, while heat from burning may alter hydration and protein residues (p. 2). Mopup and rehabilitation may also break or displace artifacts (p. 2). After a burn, the reduction in vegetation coverage may lead to increased vandalism and theft but may also facilitate recording by archeologists (p. 2). Effects of fire on lithics are a product of the inverse relationship of temperature and time. Generally, the longer and/or hotter the fire, the greater the reported damage (p. 3). Flaked stone artifacts Cherts insulated by sand will be less vulnerable to thermal shock (p. 3). Fine grained cherts are more susceptible at lower temperatures (p. 3). Chert from different sources fractures at different temperatures although most within the range of 662°F-770°F (p. 3). Impurities in the chert can result in alterations at temperatures as low as 302°F (p. 3). Between 662°F-770°F chert can become distorted, brittle and explosive in as little as 20 minutes (p. 3). Chert was often heated during the manufacture of tools and so distinguishing between deliberate cultural heating and the effects of fire can be difficult (p. 3, 4). Obsidian, a prominent tool material here in Yosemite, is also subject to fracture, cracking, crazing, potlidding, exfoliating, shattering, oxidizing, bloating, melting, pitting and become smudged, discolored, and covered with residue. Obsidian can yield location of its source through chemical analysis and the date at which it was flaked through analysis of it's hydration band. Due to foreign materials fusing to the surface of obsidian during burns, chemical analysis can be compromised (p. 5). Hydration is frequently rendered unmeasurable after wildland fires (p. 4). Hydration bands can become too diffused to accurately measure after 2 hours at 392°F and after one hour at 572°F. Hydration bands have been erased completely after 4 hours at 153°F and after one hour at 725°F (p. 4). Basalt subjected to wildfire can display angular fractures and flaking at 617°F at 30 minutes (p. 6). Quartz is highly subject to thermal expansion with a 0.36% increase (from 68°F) at 182°F, 0.78% at 392°F, 1.9% at 752°F, and 4.5% at1112°F (p. 7). Quartz undergoes changes in crystalline structure at 1064°F (p. 7). Ground stone artifacts Occasionally, ground stone was used as a heat source for cooking in stone-boiling, leading to discoloration, cracking or fracturing (p. 8). Differentiating between culturally heated ground stone and wildfire-heated ground stone can be difficult (p. 8). Thermal shock, reportedly from as little heat as that generated by sunlight, and particularly when coupled with the freezing of water in cracks and pores of rock can lead to fracturing, exfoliating and degrading of rock such as granite, basalt and limestone. Fire may be the primary agent of fracturing, spalling and weathering in boulders and rock outcrops in the western United States (p. 7). Most igneous rock (basalt, andesite, porphyry) will withstand rapid heating and cooling up to 392°F without any damage, but would begin breaking and fracturing when cooled after being heated to higher temperatures, while granites and quartzites tolerate slow temperature changes to as much as 472°F (p. 8). Magnesite decomposes at 1832°F, calcite dissociates at 1832°F. Coal, occasionally used for artifacts, is particularly vulnerable to fire as it is readily combustible. Mica, (compared to it's size at 68°F) expands 0.03% at 182°F, 0.15% at 392°F, 0.37% at 752°F, 0.66% at 1112°F and 1.3% at 1427°F. Expansion can lead to cracking and fracturing of rock and probably exfoliation of mica (p. 9). Native copper melts at 1980°F (p. 9). Corrosion and oxidation often provides a protective surface on copper at archaeological sites, unless heating cracks the corrosive film and allows it to grow inward (p. 10). There is not a lot of information yet available on the effects of fire on sites, features and artifacts. That information is on its way and as it becomes available, we will pass it along to you for incorporation into the burn plans. Below is a summary of what little we do know. Please keep in mind that the actual threshold for damage or loss of information is much lower. These are just guidelines and actual effects depend on many variables including but not limited to, surface cover, soil moisture, air temperature, air moisture, impurities in the material, rate of heating, rate of cooling. Historic artifacts tend to combine many types of materials. For example, a clock may incorporate wood, iron, brass and glass. Magnetic orientation in some ceramics and other artifacts can be an important source of information. Intense heat can alter that orientation. Protein residues, for example, blood from the animal that a artifact was used to butcher, can inform us about season of use, food types, and use patterns among other things. These residues are vulnerable to heat. Pollen is destroyed at 572°F and it is expected that other residues are affected by fire and fire retardant (p. 8). Summary of Fire Effects to Lithic Artifacts. (Deal, 2001) Material Critical Temperatures Effect Cherts > 662°F-770°F Fracture Obsidian > 392°F Hydration band diffused Obsidian > 572°F Hydration band diffused Obsidian > 153°F Hydration band erased Obsidian > 725°F Hydration band erased Basalt > 617°F Fractures Quartz 182°F 0.36% thermal expansion Quartz 392°F 0.78% Quartz 752°F 1.9% Igneous rock > 392°F Fractures Granite > 472°F Fractures? Quartzites > 472°F Fractures? Magnesite > 1832°F Decomposes Mica 182°F 0.03% expansion Mica 392°F 0.15% expansion Mica 1112°F 0.66% Mica 1427°F 1.3% Copper 1980°F Melts Calcite 1832°F Dissociates Time 20 min 2 hrs 1 hr 4 hrs 1 hr 30 min NA NA NA Rapid cooling Slow change Slow change NA NA NA NA NA NA NA Melting Points of Materials Commonly Found on Historic Sites (Haecker, 2000) Material Temperature (F) Aluminum 1220° Brass 1710° Cast iron 1920°-2550° Copper 1981° Glass 1100°-2600° Gold 1945° Iron 2810° Lead 621° Nickel 2651° Plastics 167°-509° Porcelain 2820° Pot Metal (copper-lead alloy) 562°-752° Silver 1760° Solder (tin) 275°-350° Steel (stainless) 2600° Steel (carbon) 2760° Tin 449° White Pot Metal 562°-752° Zinc 707°