Dynamic-Mechanical Properties of Polymers

advertisement

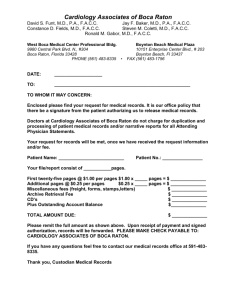

Dynamic-Mechanical Properties of Polymers Michael Hess Department of Physical Chemistry, University Duisburg-Essen, Campus Duisburg, Duisburg, Germany Department of Polymer Engineering & Science, Chosun University, KwangJu, South Korea Department of Materials Science, University of North Texas, Denton, Texas, USA 2. EXAMPLES Most of the examples by courtesy of Kevin Menard (University of North Texas, Department of Materials Science and Perkin Elmer Corp.) Tg by DMA and DSC Kevin P. Menard, Dynamic-Mechanical Analysis, CRC-Press (1999) Boca Raton Peak Tan = 140.5°C Tf Onset E’ = 133.1 °C Heat Peak E” = 136.7 °C Modulus/Pa J/g) Tan Inflection Point Onset E” = 127.3 °C Onset Onset Tan = 130.0 °C Temperature /C Temperature/C (a) (b) C Transitions are clearly seen in highly crosslinked samples # 1 epoxyresin:afriedli.1 Storage Modulus (Pa x 10 Modulus (Pa x 10 9 ) #2 9 ) 1.0 tan 4.5 0.9 4.0 0.8 3.5 0.7 3.0 0.6 2.5 0.5 2.0 0.4 1.5 0.3 1.0 0.2 0.5 0.1 0.0 0.0 50.0 100.0 heavy xlink TEMP1: 30.0 C TEMP2: 250.0 C Temperature ( TIME1: 0.0 min RATE1: 10.0 C/min 150.0 C) 200.0 tan Curve 1: DMA Temp/Time Scan in 3 Point Bending File info: afriedli.1 Thu Feb 17 12:14:11 1994 Frequency: 1.00 Hz Dynamic Stress: 800.0mN epoxyresin Static Stress: 1000.0mN 0.0 250.0 km PERKIN-ELMER 7 Series Thermal Analysis System Thu Jun 23 13:45:10 1994 This Tg is normally undetectable in the DSC!!!!!! Because the step in cp is broad and flat (hindered mobility by crosslinking) Kevin P. Menard, Dynamic-Mechanical Analysis, CRC-Press (1999) Boca Raton Blends and Copolymers Kevin P. Menard, Dynamic-Mechanical Analysis, CRC-Press (1999) Boca Raton Polymer A E’ Both Tgs Block Graft Copolymers Immiscible E’ Temperature/K Temperature/ + = Single Tg Polymer E’ E’ Exact T depends on concentration of A and B Temperature/K Temperature/K Random Copolymers & Miscible It’s not always so simple: For example, crystal-crystals slips can cause transitions Curve 1: DMA Temp/Time Scan in 3 Point Bending File info: AMPfrPP.1 Wed Oct 27 13:49:06 1993 Frequency: 1.00 Hz Dynamic Stress: 950.0mN LeBrun samples Static Stress: 1000.0mN # 1 LeBrun samples:AMPfrPP.1 Storage Modulus (Pa x 10 #2 tan (x 10 -1 9 ) ) 3.0 Tg or Alpha 1.0 1.0 T* 0.5 0.5 0.0 -150.0 -100.0 -50.0 AMP Flame Retardant Polypropylene TEMP1: -160.0 C TEMP2: 300.0 C TIME1: 0.0 min RATE1: 0.0 Temperature ( 5.0 C/min -1 (x 10 1.5 1.5 tan 9 ) Modulus (Pa x 10 2.0 2.0 ) 2.5 2.5 50.0 C) 100.0 KPM PERKIN-ELMER 7 Series Thermal Analysis System Sun Nov 26 20:58:36 1995 Kevin P. Menard, Dynamic-Mechanical Analysis, CRC-Press (1999) Boca Raton Cold Crystallization in PET DMTA Tm Tg DSC Cold Crystallization Kevin P. Menard, Dynamic-Mechanical Analysis, CRC-Press (1999) Boca Raton Left: silicon rubber with a glass transition at –117°C and a melting transition at –40°C. Beyond the melting temperature this crosslinked (vulcanised) material shows rubber-elasticity with modulus that increases with the temperature. Right: also a silicone rubber that contains silicone oil as diluent, as plasticizer. The oil causes a stress-relaxation at the beginning of the melting transition around –47°C. R. Kosfeld, M. Hess, Progr. Colloid & Polymer Sci. 66 (1979) 43-50 Dissipation of mechanical energy: Higher Order Transitions affect toughness Curve 1: DMA Temp/Time Scan in 3 Point Bending File info: AMP66gp.1 Tue Oct 26 16:05:29 1993 Frequency: 1.00 Hz Dynamic Stress: 190.0mN LeBrun samples Static Stress: 200.0mN LeBrun samples 4.0 5.5 5.0 3.5 Good Impact Strength 4.5 3.0 3.0 ) -1 2.5 Transitions 2.0 Tg 2.5 Poor 2.0 1.5 1.5 1.0 1.0 0.5 0.5 0.0 0.0 -150.0 -100.0 -50.0 AMP good part 20% glass filled Nylon 6/6 TEMP1: -160.0 C TEMP2: 300.0 C TIME1: 0.0 min RATE1: 0.0 Temperature ( 5.0 C/min 50.0 C) 100.0 150.0 KPM PERKIN-ELMER 7 Series Thermal Analysis System Sat Oct 15 14:32:54 1994 Impact was good if Tg/T was 3 or less. Kevin P. Menard, Dynamic-Mechanical Analysis, CRC-Press (1999) Boca Raton (x 10 Modulus (Pa x 10 3.5 tan 9 ) 4.0 Operating Range by DMA in 3 P o in t Ben d in g Cu rv e 1 : DM A T emp /T ime S can T h u Ju n 3 0 0 2 :1 7 :2 4 1 9 8 8 g amma_ 1 F ile in fo : Dy n amic S tress: 1 . 8 6 e+ 0 6 P a F req u en cy : 7 . 0 0 Hz S tatic S tress: 1 . 8 6 e+ 0 6 P a E P OXY P C BOARD AT 7 Hz # 1 E P OXY P C BOARD AT 7 Hz:g amma_ 1 10 ) S to rag e M o d u lu s (P a x 1 0 1 .1 5 .0 4 .5 Tg 0 .8 10 ) Operating range ) 4 .0 ) (b) 0 .9 -1 (x 1 0 Beta 1 .0 3 .5 2 .5 Operating range 0 .5 0 .4 2 .0 1 .5 1 .0 0 .2 0 .5 0 .1 0 .0 0 .0 T emp eratu re ( TEM P1 : TEM P2 : in 3 P o in t Ben d in g Cu rv e 1 : DM A T emp /T ime S can AM P frP P . 1 W ed Oct 2 7 1 3 :4 9 :0 6 1 9 9 3 F ile in fo : Dy n amic S tress: 9 5 0 . 0 mN F req u en cy : 1 . 0 0 Hz S tatic S tress: 1 0 0 0 . 0 mN L eBru n samp les - 180. 0 300. 0 # 1 L eBru n samp les:AM P frP P . 1 S to rag e M o d u lu s (P a x 1 0 #2 t an (x 10 -1 0. 0 TI M E1 : C C 9 m in RATE1 : C/ m i n 3 .0 1 .0 1 .5 1 .0 0 .5 0 .5 0 .0 - 160. 0 300. 0 C C TI M E1 : 0. 0 m in RATE1 : T emp eratu re ( 5. 0 C/ m i n 5 0 .0 0 .0 -5 0 . 0 -1 0 0 . 0 -1 5 0 . 0 AM P F lame Retard an t P o ly p ro p y len e TEM P 1 : TEM P 2 : C) -1 t an Modul us (P a x 10 Operating range 1 .5 ( x 10 ) 2 .0 2 .0 ) 2 .5 2 .5 9 10. 0 ) ) 1 0 0 .0 KP M P E RKIN-E L M E R An aly sis S y stem 7 S eries T h ermal S u n No v 2 6 2 0 :5 8 :3 6 1 9 9 5 1 0 0 .0 0 .0 -1 0 0 . 0 C) 2 0 0 .0 P E DM A7 R&D L AB P E RKIN-E L M E R An aly sis S y stem 7 S eries T h ermal S u n No v 2 6 2 0 :1 3 :5 3 1 9 9 5 t an M odul us (P a x 10 3 .0 0 .6 ( x 10 0 .7 0 .3 (c) -1 (a) -> # 2 t an Analysis of a Cure by DMA E’-E” Crossover ~ gelation point 10 8 10 7 Modulus 10 6 106 Pa ~ Solidity 10 5 vitrification point E” 10 4 Curing 10 3 E’ 10 2 Melting Minimum Viscosity (time, length, temperature ) 10 1 10 0 50.0 70.0 90.0 110.0 130.0 150.0 right figure after J. K. Gillham, Encyclop. Polym. Sci. Technol. (1986) 2nd ed.; J. K. Gillham, Polym. Eng. Sci. (1979) 19, 676 DMA’s advantage is viscosity information along with Ea and k 8.0 7.0 6.0 5.0 4.0 T=70 3.0 2.0 T=60 T=50 1.0 0.0 0.0 5.0 10.0 15.0 20.0 25.0 From Isothermal Data, you... log Plot log vs. time for each T to get and k. Then plotting the of log of these against 1/T gives us Ea and E log Slope = Ea time in sec. Kevin P. Menard, Dynamic-Mechanical Analysis, CRC-Press (1999) Boca Raton 1/T K Postcure studies allow process optimization: 1.0 Postcure time vs... Tg and E’ 1 hour 0 hours 2 hours 200 180 3 - 8 hours 160 140 120 tan Property 0.5 100 E'@ 50 (e9 Pa) 80 60 E' onset 40 tan d peak 20 0.0 tan d onset 0 150 175 200 Temperature 0 Kevin P. Menard, Dynamic-Mechanical Analysis, CRC-Press (1999) Boca Raton 2 4 Time in H ours 6 8 Kevin P. Menard, Dynamic-Mechanical Analysis, CRC-Press (1999) Boca Raton Multiplexing… Instead of just the Tg Sheet Film Fiber multiple frequencies in one run Kevin P. Menard, Dynamic-Mechanical Analysis, CRC-Press (1999) Boca Raton Or you can use the Synthetic Oscillation Mode Take five frequencies Sum together And apply the complex wave form to the sample Temperature in C Kevin P. Menard, Dynamic-Mechanical Analysis, CRC-Press (1999) Boca Raton We can then do further analysis Activation energy Master curve ??????0.01?100Hz? Why?… Kevin P. Menard, Dynamic-Mechanical Analysis, CRC-Press (1999) Boca Raton Master Curves extend the range • We can collect data from 0.01 to 100 Hz. • If we do this at many temperatures, we can “superposition” the data. TTS • After TTS, our range is 1e-7 to 1e9 Hertz (1/sec) • Then x scale can then be inverted to get time To Review, DMA ties together... molecular structure Molecular weight MW Distribution Chain Branching Cross linking Entanglements Phases Crystallinity Free Volume Localized motion Relaxation Mechanisms product properties Material Behavior processing conditions Stress Strain Temperature Heat History Frequency Pressure Heat set Dimensional Stability Impact properties Long term behavior Environmental resistance Temperature performance Adhesion Tack Peel