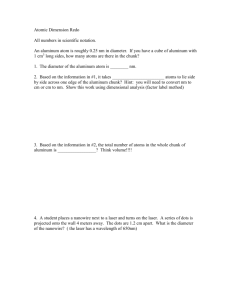

Conditions of Aluminum Industry in 2004

advertisement

1 Conditions of Aluminum Industry in 2004 Aluminum is an important metal because of many outstanding qualities including high strength per weight unit, good conduction, lightness, stainlessness, ability to be easily formed with many methods and recycled without quality changed. Therefore, it has been used as raw material for important related industries such as construction industry, packaging industry and electrical industry. It has good trend in the motor vehicle industry because of its good feature. It is light with the proportion of 1/3 of iron weight, helping to save the energy and potential pollution. It is also highly safe due to good absorb kinetic energy in case of car accidents that the body made of aluminum would absorb the kinetic energy from the structure first, reducing the damage in the passenger room. In addition, in other countries, inside the trailer truck, they use aluminum as the body by 90% of the total body weight, reducing the weight by 1800 kilogram from the use of iron as truck body structure. This enables the truck to load more weight without over road weight limit. However, aluminum is used only in expensive passenger car. Several overseas companies are accelerating the development to use more aluminum in motor car. In 2005, Hindalco Industries is cooperating with TATA Motors to develop the aluminum structure for commercial cars especially aluminum structure for truck, which is expected to be produced within year 2005. Aluminum industry can be classified into 3 production types. - - Primary production starts from bauxite extraction, which produces alumina refining to be processed into the electrolysis or called primary smelting to produce the primary aluminum. Four tons of bauxite can produce 2 tons of alumina, which will change to 1 ton of primary aluminum. Recycling the metal scrap to be re-melted can also produce aluminum, which can be reproduced to be the original products (Same Application) without down grade. Intermediate production is metal rolling to be foil, extrusion, wire deep drawing, and casting. Final production is bringing the aluminum from the intermediate production to produce the finished products for consumers. Production cycle of aluminum is shown below. 1. Aluminum conditions in global market 1.1. Production At present, the total primary aluminum production in global market is about 28 million tons per year, coming from 120 aluminum smelteries worldwide. 7 million tons are from recycle. Production volume and capacity can be shown in the table below. 2 Country Production Production Capacity 2003 2004 China 5.45 6.5 5.7 6.8 Russia 3.48 3.6 3.5 3.6 Canada 2.79 2.64 2.8 2.85 U.S. 2.7 2.5 4.14 4 Australia 1.86 1.88 1.85 1.88 Brazil 1.38 1.45 1.42 1.45 Norway 1.15 1.25 1.2 1.3 South Africa 0.7 0.82 0.7 0.85 Venezuela 0.6 0.6 0.64 0.64 Mozambique 0.43 0.51 0.44 0.54 Others 7.16 7.5 8.11 8.4 Total 27.7 29.25 30.5 32.3 Source: U.S. Geological Survey, Mineral Commodity Summaries, January 2005 2003 1.1.1 2004 Aluminum production growth in global market classified by regions Graph: Production growth classified by regions Source : Macquarie Research, October 2004 Although there is an expectation for the declining growth of manufacturing sector as a result of global economic slowdown, China remains the country having the highest growth in aluminum production in global market. In North America, the production has declined due to workers’ strike, which is expected to resume the production in quarter 1-2 of year 2005. 1.2 Demand for aluminum consumption in global market Country/Demand 2004 China 6 European countries 6.4 U.S. 6.4 Asia 4.3 CIS countries 1 Others 3.3 Total 29.9 Source: Macquarie Research, October 2004 Remark: E = Estimate 2005 E 6.7 6.6 6.4 4.5 1 3.6 31.4 2006E 7.6 6.8 6.5 4.7 1.2 3.8 33.1 Graph: Demand for aluminum consumption classified by regions Source: Macquarie Research, October 2004 In 2004, the demand for aluminum consumption is higher due to demands of China and U.S. Demand for global aluminum consumption in 2005 is expected to increase by 5% while the production sector grows by 4%. Therefore, at the end of 2005, inventories would greatly decline probably resulting in higher price of aluminum in London Metal Exchange market. 3 1.3 Aluminum and its application 1. 2. 3. 4. 5. Transportation industry such as motor cars, trucks, ships, trains, airplanes, constituting 26% of total aluminum consumption. Packaging industry such as beverage can, aluminum foil used in medicine and food industries, constituting 20% of total aluminum consumption. Construction industry such as window and door frames, bridge and basic structures, heater equipment, constituting 20% of all aluminum consumption. Electrical industry such as transmission line, transmission tower, constituting 9% of all aluminum consumption. Others such as machinery, sport equipment, decorative furniture, consumer goods such as refrigerator, television, washing machine, constituting 25% of all aluminum consumption. Aluminum Consumption 1.4 Main primary aluminum manufacturing countries 1.4.1 China - Production: Primary aluminum has been produced most in the world (6 million tons) with the most demand in the world (about 6 million tons) as well. It is also expected that aluminum production would exceed domestic demand in the next 12 years. As a result, China begins to export aluminum to the world market during such period. However, after the year 2007, it is expected that consumption would exceed production volume again and China would become the aluminum net importer. - Resources: Source of bauxite is about 2.3 trillion tons, which is 2% of all sources in the world. But the quality of bauxite texture is not good enough to smelt to alumina. So, China needs to import alumina mainly from Australia and India. The important primary aluminum production company is Chalco, which Chinese government holds 72% of its share. - Consumption Aluminum consumption rate increases by 14% in 1998-2001. When compared with the world in the same period (excluding China), it is 3.9% from the growth of construction and motor vehicle industries, and electrical energy production, which is highly demanded continuously. China, at present, has higher growth of basic industries (Metal Intensive), as compared with Japan in 1947 or Korea in 1957 but the size is much larger. More than 80% of aluminum consumption in China is used in the construction business. Recently, demand might be rapidly higher due to Olympic 2008 construction project. Projects under the construction are 42 race fields and 50 hotels, etc. In the developed countries, aluminum application in construction industry has 4 only 30%, whereas another 70% has been used in other industries. To achieve this, China might have to take no less than 30-40 years, at least. At present, China consumes 2-3 kilograms of aluminum per person and compared with the U.S., which consumes 35 kilograms/person. It can be seen that the trend of consumption demand for aluminum in China remains high. - Affecting Factors - There is a problem of electrical energy shortage in the west and south of the country. Such areas have the production of primary aluminum in half of all production capacity. China has expedited the problem-solving and it is expected to succeed in 2011. - According to China’s access to WTO, China tries to close the pure aluminum smelters with pollution problem. These factories have the total production capacity of 450,000 tons. The factories with the production capacity of less than 50,000 tons will be closed down because of their ineffective productions, and most of them are old factories and use technology causing more pollution. In addition, there are problems of electrical energy shortage and source of alumina raw material that need to be imported from abroad. Moreover, the Chinese government has used a measure to restrict alumina import to decelerate the rapid expansion of primary aluminum production to prevent over production capacity problem. Therefore, it seems far from possibility that China would become the exporting country of aluminum and affect the global market like Russia did in the past (in 1992). At present, China uses tax measure to restrict aluminum export at 5% and, in October 2004, Ministry of Commerce of China announced the restriction for aluminum smeltery with the production capacity of less than 100,000 kilograms/year. It prohibited the direct import of alumina raw materials, which have to import through large smeltery. This would increase the production cost of small aluminum smeltery. As a result, China’s export might not change much from last year to maintain the balance of demand for domestic aluminum consumption and alleviate the problem of electrical energy shortage in the country. 1.4.2. United States of America - Production and Import – Export can be shown in the table below. Production 2003 (1,000 tons) 2004 (1,000 tons) Primary Aluminum 2,700 2,500 Secondary Aluminum 1,070 1,200 Import 4,130 4,300 Canada (58%), Russia (18%) Export 1,540 1,700 Canada (51%), Mexico (20%), China (16%) Source : U.S. Geological Survey, Mineral Commodity Summaries, January 2005 - Domestic Consumption: total 6.5 million tons, classified as follows. 2004 (100%) Transportation 35% Packaging 24% Building 16% Consumer durables 8% Electrical 7% Others 10% 5 2. Situation of Aluminum in Thailand In Thailand, there are 3 production processes. However, in the basic production, there is only melting the aluminum from metal scrap, which is Secondary Aluminum. There is no primary aluminum production because of shortage of bauxite raw material sources and high electricity expenses in the country, which is not worth commercially investing. 2.1 Production Aluminum industry in Thailand can be classified into 3 groups based on production process. 1) Primary producers - factories purchase metal scrap and aluminum waste as raw materials for re-melting to be unwrought or wrought aluminum then casting, according to the needs of related industries. 2) Intermediate producers - can be divided into 2 groups that are extrusion factory and aluminum sheet factory, such as aluminum sheet and foil producers, cut-off string aluminum, electrical wire producers, casting and die casting factories. 3) Final producers - producers who purchase and use the aluminum sheet as raw materials to produce consumer products. The examples are beverage can and packaging producers, container producers, building decorative item, banners etc. 2.1.1 Problem of Production Problem is a lack of upstream industry that is the production of primary aluminum, so Thailand needs to rely on import of semi-finished raw materials (unwrought aluminum) and re-melting the aluminum scrap and waste (secondary aluminum). However, the quality of aluminum obtained from re-melting the aluminum scrap is not quite purified because of no electrical sorting process to make it more purified. The campaign of aluminum storage for recycle has not been successful. Primary producers, which are smelteries, are still facing the shortage of raw materials that are insufficient aluminum scrap. Therefore, import from abroad is needed even though the domestic circulation quantity is about 100,000 tons per year, which can substitute to some extent. The wrought aluminum factories, such as rolling, pressing, extrusion factories, foundry etc., will always leave metal scrap. Most of these factories do not have their own furnaces, so they will sell metal scraps by auction to metal scrap dealers or smelteries or make the contract with aluminum raw material suppliers to resell them to be re-melted. Aluminum scrap from this industrial factory has good quality (New Scrap). Due to no systematic storage of old scrap and high price of aluminum scrap in overseas, the aluminum scrap is continuously exported every year. 6 2.2 Foreign Market Import Table 1: Comparison of aluminum import quantity in 2003 and 2004 QTY: Metric Ton, VALUE: Million Baht Products 2002 QTY 2003 QTY 2004 Scrap 17,602 VALU E 890 22,364 VALU E 1,158 QTY 31,177 VALU E 1,767 Unwrought 259,323 16,343 330,317 20,128 417,669 Powders & Flakes 671 62 864 78 Bars, Rods, Profiles 2,615 359 4,278 Wire 2,741 314 Plates, Sheet, Strip Foil 61,025 % Changing rate QTY VALUE 39.4 52.5 28,091 26.4 39.5 1,021 75 18.7 -3 575 4,140 679 -3 18 2,634 311 3,258 366 23.7 17.7 6,805 70,755 7,804 80,948 9,354 14.4 19.9 21,685 3,693 26,570 4,290 33,274 5,492 25.2 28 Tubes, Pipes, Fittings Structures 2,160 743 2,391 890 3,090 1,102 29.3 23.8 NA 262 NA 231 NA 494 - 114 Container, packaging Household articles and Sanitary ware others NA 612 NA 787 NA 829 - 5.3 NA 75 NA 74 NA 128 - 73 NA 9,456 NA 11,571 NA 11,222 - -3 Total 367,822 39,614 460,173 47,897 574,577 59,599 24.8 24.4 Source: Important source of import Singapore, U.S., UK Australia, UAE, Russia Germany, Austria, China, Japan Japan, Indonesia, Bahrain, China France, Netherlands Japan, Korea, Australia Japan, Korea, Malaysia Japan, Malaysia, South Korea China, Malaysia, South Korea, Indonesia France, Italy, Denmark Taiwan, South Korea, China Japan, China, Singapore Japan, Australia, China 1. Industrial Economics Information Center, Office of Industrial Economics 2. The Customs Department From the aluminum import quantity table in 2004, compared with 2003, the overall import has increased in all categories. The most imported product is unwrought aluminum with the import value of 28,091 million baht from the total import value of 59,599 million baht or 47% of total import value. Thailand’s main aluminum import markets are Japan, Australia and China respectively, unchanged from year 2003. 7 Export Table 2: Comparison of aluminum export quantity in 2003 and 2004 QTY: Metric Ton, VALUE: Million Baht 2002 Products 2003 2004 % Changing rate QTY VALUE QTY VALUE QTY VALUE QTY VALUE Scrap 15,320 708 17,560 737 20,662 944 17.6 28 Unwrought Powders & Flakes Bars, Rods, Profiles 9,674 11 13,949 586 2 1,020 6,905 143 17,052 452 10 1,224 12,312 161 22,488 902 12 1,746 78.3 12.6 31.9 99.5 20 42.6 Wire 167 11 149 11 347 14 132.8 27.3 Plates, Sheet, Strip 3,870 372 7,612 664 9,926 1,022 30.4 54 Foil 2,320 341 2,321 346 3,526 544 52 57.2 Tubes, Pipes, Fittings 1,764 458 2,342 533 2,808 665 19.9 24.7 Structures Container, packaging NA NA 5,406 1,478 NA NA 6,873 1,439 NA NA 9,125 1,887 - 32.7 31.1 Household articles and Sanitary ware Others NA 4,284 NA 3,706 NA 4,001 - 7.9 NA 1,864 NA 1,635 NA 3,042 - 86 47,075 16,530 54,084 17,630 72,230 23,904 33.5 35.6 Total Source: Important source of export Japan, South Korea, China Indonesia U.S., Australia Hong Kong, India, Vietnam, Australia Burma, Singapore, Vietnam Japan, Malaysia Malaysia, Philippines, Indonesia Malaysia, Indonesia, UK Japan Malaysia, Japan U.S. Japan, Netherlands, Hong Kong, Philippines Japan, U.S., Malaysia 1. Industrial Economics Information Center, Office of Industrial Economics 2. The Customs Department From the aluminum export quantity table, the overall export has increased from 2003 by 35.6% with the total export value in 2004 of 23,904 million baht. Thailand’s main export markets are Japan, U.S. and Malaysia. 3. Summary Aluminum industry in the country continues to grow continually as seen from the import quantity and value of aluminum, which tends to increase continually. It indicates that this industry grows favorably as a result of high consumption demand of related industries such as construction industry, packaging industry, electrical appliance industry that has increased production including rice cooker, television, refrigerator, washing machine. However, if considered the product export statistics of quantity and value figures, it might not be able to show that to what extent the aluminum industry has grown because aluminum has been used as raw materials to produce the finished products for related industries and will be tax-imposed by customs code based on such industries. Therefore, it can be said that the growth of aluminum industry depends on the related industries that use aluminum as raw 8 materials. When looking at the trend of consumption quantity of aluminum products in related industries, it still grows favorably in conjunction with national economy in the next 1-3 years which is expected to grow well also. Therefore, the domestic entrepreneurs have to quickly develop the product quality to add value in their products and adopt various management principles to enhance production performance and reduce the costs. The principles of Total Quality Management, Cleaner Production, and Lean Manufacturing, etc., can be applied in the factories for continual improvement of competitiveness. However, if domestic entrepreneurs do not develop product quality, the market might be shared by imported products. Therefore, domestic entrepreneurs need to accelerate the development of product quality and standard continually to maintain the existing markets and, at the same time, the new markets. As Thailand does not have domestic upstream industry, raw materials need to be continually imported from abroad to process into semi-finished or finished products for consumers. When considered basic raw material imports of aluminum, namely unwrought aluminum, it has import value at 47% of total import value or 28,091 million baht from 59,599 million baht. Therefore, searching for alliance or world class supplier/partnering to secure supply in ordering more raw materials is the main issue for domestic entrepreneurs to consider, as in the future the competition will not be in one particular region but will spread all over the world. As for the smelteries that smelt aluminum scrap or dross to be ingot aluminum (secondary aluminum), they still need to continually develop the production techniques to enhance performance and reduce environmental problems with lower cost to satisfy the potential customers’ needs for higher quality and standard. Thai entrepreneurs should quickly develop the substitution for import of aluminum sheet and foil, which can be domestically produced, but imported with higher quantity and value every year. In 2004, import value of aluminum sheet is 9,354 million baht, increasing from 2003 by 19.9% and from 2002 by 37.45%. Import value of aluminum foil in 2004 is 5,492 million baht, increasing from 2003 by 28% and from 2002 by 48.7%. Both products tended to be imported more because they are raw materials for domestic consumer goods and exported products with good growth trend in line with the national economic conditions. Such products are air-conditioner, refrigerator, container, beverage, food and medicine. However, aluminum sheet and foil products used as raw materials of such mentioned consumer goods are very competitive as seen from their import quantity and value. Thai producers of aluminum sheet and foil need to import primary raw materials from abroad and then roll or form them. This might be affected by exchange rate and fluctuating price of aluminum in global market. Therefore, aluminum sheet and foil producers should quickly develop quality and build up customer driven linkage to be accepted as one of the most appropriate alternatives for them. 4. Recommended Measures for the Government 4.1 Establishment of recycle center is to develop the effective full-cycle waste management and reduce waste quantity for the environmental benefit. This can be done by appropriate disposal, sorting the unused wastes by type, which some types of wastes can be recycled. Collect Reuse Recycle Disposal Aluminum scrap is an important raw material for aluminum production. In 2004, Thailand imported 31,177 metric tons of aluminum scrap, increasing by 39.4% compared with 2003. Its export is still high at 20,662 metric tons, increasing by 17.6% from 2003 in 9 spite of insufficient domestic use. Exported scraps can be divided into 2 types that are new scrap and old scrap. Scrap outputs from this production have good quality with high price and demand, which most finished aluminum producing companies will export to raw material producers according to their agreements. However, the ban control for export of aluminum might be difficult to implement. Incentive measures and cooperation establishment among producers would be more appropriate than forcing measures of the government. Therefore, systematic aluminum scrap collection might be an alternative to reduce the shortage of aluminum scrap to some extent and reduce its import quantity from abroad. Besides, campaign for knowledge and reinforcement of waste sorting should be made especially used aluminum scraps, such as beverage can, decorative equipment, electrical appliance parts, window frame, etc., because all of them can be recycled. For example, at present, some factories and schools have collected used aluminum beverage cans and the purchasers come to buy them on site each month. These factories or schools can earn income from used aluminum scraps, which rewards them as incentives and helps conserve the environment. Another example is in the golf course where there are a number of aluminum beverage cans each day, which can be additional income for golf caddy who collects and sells used beverage cans to the dealer and receives immediate cash, influencing them to collect more, etc. 4.2 Consideration on Packaging Tax Collection Aluminum scrap has high value when compared with other material scraps that have not been all recycled and it is highly demanded by industrial factories. From the survey of aluminum scrap in piles of wastes in many areas in Thailand, it is found that there is less scrap remained. This shows high demand for aluminum scrap in the country. The sorting of solid waste of aluminum might not be right but it is probably higher value product than solid wastes. Therefore, aluminum package tax collection or tax of other products should be considered with the effect on the whole Life Cycle Assessment (LCA) of aluminum products. Recycle rate of aluminum and aluminum package, and pollution to the environment caused by aluminum products are necessary issues to be considered prior to tax measure implementation. 4.3 Enhancement of Competitiveness of Aluminum Industry As mentioned above, Thailand does not have upstream industry due to shortage of raw material source and limitation on electrical energy cost. Therefore, development of products that can be produced domestically and value added acceleration to expand into overseas markets should be promoted. Also, the promotion should be made for potential products that can substitute for long-term import. This can be done by considering the use of Local Content in appropriate amount by applying incentive measures such as tax incentive or others. Entrepreneurs should quickly establish a network for the whole system of industries including producers and users. 4.4 FTA Consideration Tax consideration under the FTA should be made with the competitive productivity of domestic entrepreneurs and the main benefits of producers, users and trading partners in each product because tax reduction, in some cases, would give the opportunity to the same products from abroad to compete with domestic entrepreneurs rather than support the market expansion. Therefore, the study of impact from tax measures needs to be conducted carefully. However, the FTA consideration regarding aluminum products should be made in the following scopes. 1. 2. Production procedure and technology of the trading partners Production capacity, good quality aluminum production capacity 10 3. 4. 5. 6. 7. 8. 9. 5. Structure of production cost The whole tax structure of products Import – export quantity with trading partners Product control standards Domestic and abroad consumptions and future trend Production capacity and domestic entrepreneurs’ production plan Demand of related industries Trend As for 2005, aluminum industry is expected to continuously grow, particularly sheet and foil products, structure aluminum and parts used in construction business including unwrought aluminum products, which are raw materials for related industries such as consumer goods, packaging, beverage and food. They have good growth trend in line with the national economy that is expected to further grow well. However, price of primary aluminum tends to increase continuously as a result of huge decrease of inventories in London Metal Exchange (LME). ---------------------------------------------------------------------------------------------Mr. Danuruj Winmun Industrial Sector 2, Sectoral Industry Policy Bureau 1 Office of Industrial Economics April 2005