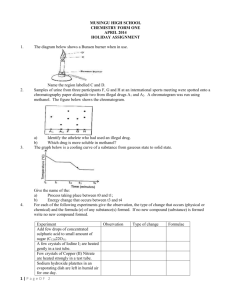

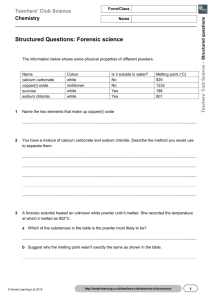

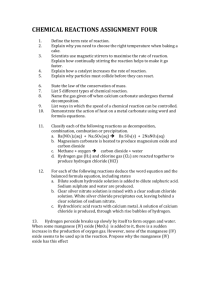

stearate prescription

advertisement