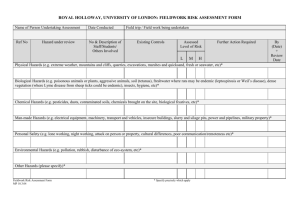

Hazard Hunt

advertisement

Miscellaneous ________________________________ Barricades & signs (yours) MSDS information Gas bottles or cylinders secured Other__________________________ ________________________________ ________________________________ Personal Protective Equipment Required Hardhat Safety glasses Hearing protection Gloves (leather, kevlar, mechanics & etc.) Face shield Goggles Sleeves (leather, kevlar, welding & etc.) Harness & lanyards Reflective vest/high visibility clothing Personal floatation device FR or Nomex clothing Flash protection Respirator LOTO lock Other__________________________ Task Completion List Y N All permits signed Y N Work area cleaned Y N All tools secured Y N Locks have been removed Y N Was anyone injured Y N Was there a Near Miss Plans to Eliminate or Control the Hazard ________________________________ ________________________________ ________________________________ ___________/__________/ 20__________ Date ____________________________________ Team Member ____________________________________ Supervisor Review ____________________________________ Task Team Member Hazard Hunt Notes & Comments ________________________________ Stop Hazards Dead ________________________________ ________________________________ ________________________________ ________________________________ ________________________________ ________________________________ ________________________________ ________________________________ ________________________________ Supervisor sign off Miscellaneous ________________________________ Barricades & signs (yours) MSDS information Gas bottles or cylinders secured Other__________________________ ________________________________ ________________________________ Check for all potential hazards that may occur during task List all identifiable hazards List all plans to eliminate hazards DISCLAIMER: This safety form is a sample document provided by the AISC Safety Committee to be used in the shop or field. It is a sample form only and is intended to be modified by a competent person to meet the specific needs of your facility and operations. AISC is not responsible for the risks involved in using this form. ___________/__________/ 20__________ Date ____________________________________ Team Member ____________________________________ Personal Protective Equipment Required Hardhat Safety glasses Hearing protection Gloves (leather, kevlar, mechanics & etc.) Face shield Goggles Sleeves (leather, kevlar, welding & etc.) Harness & lanyards Reflective vest/high visibility clothing Personal floatation device FR or Nomex clothing Flash protection Respirator LOTO lock Other__________________________ Task Completion List Y N All permits signed Y N Work area cleaned Y N All tools secured Y N Locks have been removed Y N Was anyone injured Y N Was there a Near Miss Plans to Eliminate or Control the Hazard ________________________________ ________________________________ Supervisor Review ________________________________ ____________________________________ Task Team Member Hazard Hunt Notes & Comments ________________________________ Stop Hazards Dead ________________________________ ________________________________ ________________________________ ________________________________ ________________________________ ________________________________ ________________________________ ________________________________ ________________________________ Supervisor sign off Check for all potential hazards that may occur during task List all identifiable hazards List all plans to eliminate hazards List the Steps Required to Perform the Task ________________________________ ________________________________ ________________________________ ________________________________ ________________________________ ________________________________ ________________________________ ________________________________ ________________________________ Equipment Working with hand tools Working with power tools Using equipment Using gas cylinders Other__________________________ Identify Hazards Personal Limitations No procedure for the task Not trained on tools to be used First time performing the task Distractions in the area Instructions not clear/understood Other__________________________ List the Steps Required to Perform the Task ________________________________ ________________________________ ________________________________ ________________________________ ________________________________ ________________________________ ________________________________ ________________________________ ________________________________ Equipment Working with hand tools Working with power tools Using equipment Using gas cylinders Other__________________________ Identify Hazards Personal Limitations No procedure for the task Not trained on tools to be used First time performing the task Distractions in the area Instructions not clear/understood Other__________________________ Emergency Evacuation Evacuation signal Evacuation route Evacuation location Communicating the plan General Housekeeping Barricades & signs in place (others) Hazmat & other chemicals contained & labeled Spotters required Other__________________________ Permits Required Hot work Confined space entry Ergonomics Hazards Awkward body positions Too heavy/awkward to lift (over 50 lbs.) Walking area not clean or uneven Repetitive motion Prolonged twisting or bending Body parts in line of fire Other__________________________ Work Environment Hazards Slipping or tripping hazard Limited access/egress Adequate lighting Position of hands Exposure to high/low temperatures Exposure to steam/chemicals Exposure to loud noise Exposure to dust Working over water Holes covered & indentified Emergency Evacuation Evacuation signal Evacuation route Evacuation location Communicating the plan General Housekeeping Barricades & signs in place (others) Hazmat & other chemicals contained & labeled Spotters required Other__________________________ Permits Required Hot work Confined space entry Ergonomics Hazards Awkward body positions Too heavy/awkward to lift (over 50 lbs.) Walking area not clean or uneven Repetitive motion Prolonged twisting or bending Body parts in line of fire Other__________________________ Work Environment Hazards Slipping or tripping hazard Limited access/egress Adequate lighting Position of hands Exposure to high/low temperatures Exposure to steam/chemicals Exposure to loud noise Exposure to dust Working over water Holes covered & indentified Others working below/overhead Other__________________________ What are the Potential Hazards ________________________________ ________________________________ ________________________________ ________________________________ ________________________________ ________________________________ ________________________________ Eliminate the Hazards Working at Heights Harness required Tie-off points identified Materials & tools secured Elevated work area complete (handrail, midrail, & toe boards) Planks & bed ladders tied down Scaffold tagged & inspected Ladders tied off Equipment & Tool Requirements Guards/proper attachments applied (ZES when changing) Straps to secure tool, load, pipe & etc. Daily inspection on all equipment Others working below/overhead Other__________________________ What are the Potential Hazards ________________________________ ________________________________ ________________________________ ________________________________ ________________________________ ________________________________ ________________________________ Eliminate the Hazards Working at Heights Harness required Tie-off points identified Materials & tools secured Elevated work area complete (handrail, midrail, & toe boards) Planks & bed ladders tied down Scaffold tagged & inspected Ladders tied off Equipment & Tool Requirements Guards/proper attachments applied (ZES when changing) Straps to secure tool, load, pipe & etc. Daily inspection on all equipment