Potassium Hydride

advertisement

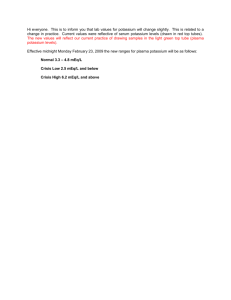

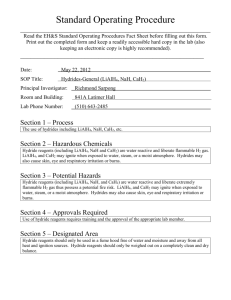

Standard Operating Procedure ________________________________________________________ Read the EH&S Standard Operating Procedures Fact Sheet before filling out this form. Print out the completed form and keep a readily accessible hard copy in the lab (also keeping an electronic copy is highly recommended). ______________________________________________________ Date: May 22, 2012 SOP Title: Potassium Hydride Principal Investigator: Richmond Sarpong Room and Building: 841A Latimer Hall Lab Phone Number: (510) 643-2485 Section 1 – Process Section 2 – Hazardous Chemicals Potassium hydride is a highly moisture sensitive reagent that reacts violently with air and/or water. Upon reaction with water, it can ignite. Section 3 – Potential Hazards Potassium hydride is extremely flammable upon exposure to water, and as such is generally sold as a dispersion in mineral oil. It must be handled under an inert atmosphere to minimize exposure to both air and moisture. It can cause severe burns and is highly corrosive. In addition to the high flammability, potassium hydride is extremely destructive to the tissue of mucous membranes. Section 4 – Approvals Required Use of potassium hydride requires training and the approval of the appropriate lab member. Section 5 – Designated Area Potassium hydride should only be used in the fume hood. Section 6 – Special Handling Procedures and Storage Requirements Clear all areas where the reagent will be opened prior to use. Do not use any potassium hydride while working alone. Weigh the desired amount of the potassium hydride/mineral oil suspension in a beaker. Wash the potassium hydride three times with dry hexanes (20 mL/g KH) and suspend the washed potassium hydride in the dry, ethereal solvent (THF, Et2O) of choice. Transfer the suspension to a flame-dried flask equipped with a stir bar. Next, fit the flask with a septum, pierce the septum with a clean, dry needle attached to a Schlenk line, and purge the flask with nitrogen. A typical purge procedure is as follows. First, evacuate the reaction vessel using a vacuum pump attached to the Schlenk line until the solvent begins to boil (indicated by bubbling). Then, replace the atmosphere above the solvent with nitrogen gas delivered via the Schlenk line. Finally, repeat this procedure twice more to ensure that all of the air has been removed from the flask. After successfully weighing out the potassium hydride, the substrate and any addition reagents can be added to the flask. After the reaction vessel has been cooled to the desired temperature, slowly add a solution of the substrate, prepared with the same dry, ethereal solvent as above, through the septum using a cannula (volumes > 15 mL) or syringe (preferred for smaller volumes) while continuing to supply an inert atmosphere via the Schlenk line. Upon completion of the desired reaction, excess potassium hydride can be quenched by adding excess butanol dropwise to a reaction vessel cooled to 0 ° C followed by the dropwise addition of excess cold water. Section 7 – Personal Protective Equipment Wear a laboratory coat made of flame-retardant material or cotton. Wear flame-resistant gloves over the top of chemically resistant gloves, and safety glasses. Section 8 – Engineering/Ventilation Controls Work inside the hood. Keep the hood sash as low as possible to prevent spills/splashes outside the hood. Section 9 – Spill and Accident Procedures In case of a fire, use Metal-X, soda ash, or sand for small fires. For large fires, use an ABC fire extinguisher. Do not use water on the fire. In case of contact with your person, get to the nearest safety shower immediately. Remove all contaminated clothing and get underneath the running water quickly. The large amount of water should put out the fire. Section 10 – Waste Disposal Fully quench the reagent before disposal. To quench potassium hydride, dilute the concentration of potassium hydride below 5 % w/v with dry hexane. Cool the resulting solution to 0 ° C and add excess t-butyl alcohol dropwise under nitrogen with stirring. Then, add excess cold water dropwise. Separate the resulting aqueous and organic layers. The aqueous layer can be neutralized and disposed in the sink. The organic layer can be disposed as normal solvent waste. Section 11 - Decontamination Remove all contaminated clothing, wash all contaminated skin with copious amounts of water. Section 12 – Process Steps Process Steps Safety Measures Training Documentation Name (Printed) Signature Date