11th PLAN (2007-2012) - Central Wool Development Board

advertisement

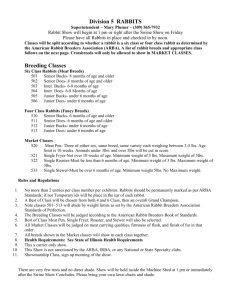

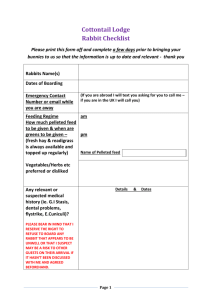

A. Angora Wool Development Scheme In India, Angora Rabbit Wool is produced in hilly areas of Uttaranchal, Himachal Pradesh and other hilly areas where climatic conditions were found suitable. The total Angora population in the country is around 50,000 and approximately 30,000 Kg. wool is produced annually. The Angora Rabbit Wool can be used by mixing with other fibres in knitwears, shawls and worsted suiting. At present very few mills in Ludhiana region are processing this fibre on woollen system to produce knitting yarn. The Angora Wool produced in the country is not of uniform quality making it difficult to develop a suitable processing system. Consequently, we are importing yarn of Angora Wool for knitwear sector. Apart from it, we are also importing wool slivers of this fibre, which is blended with wool & silk in the country. Keeping in view the importance of the fibre and the potential for employment generation, there is need to increase production and productivity of the Angora Wool by making Rabbit rearing a popular occupation. High profitability, vast potential of employment generation, huge potential for earning foreign exchange and role of Angora rabbits husbandry in ecological rehabilitation are few of the many positive factors, which call for coordinated efforts, so that the farmers take up angora rearing in a big way, particularly the educated unemployed youth. The people in the village have understood the favorable economics and livelihood potential of angora farming. The educated unemployed youth can take up this profession and traditional farmers can also supplement their income through this profession. With this in view, the Central Wool Development Board engaged with an integrated approach for the development of Angora rabbit farming in the country. In the 10th Plan, the CWDB implemented Angora development programme to support angora-rearing activity among farmers, strengthening of GPC, distribution of rabbits among farmers as foundation stock along with necessary training and feed and nutritional support. It also provided inputs for Common Facility Centres, designs, skill up-gradation and improved marketing opportunities to the farmers to encourage the processing of wool by the grower so that the economic benefit and other inputs and value addition to him could be maximized. Looking the economic returns from processed Angora Fibre, the potential for employment generation in hilly remote areas, the dearth of sustainable livelihood alternatives; it is proposed to continue efforts at angora development project on large scale for production and marketing of angora wool, yarn and hand made angora woollen garments to generate employment and raise family income, keeping young men and women in their native villages, by adopting integrated approach. D:\116106756.doc 1 Project objectives i) ii) iii) iv) v) vi) vii) The main objectives of the projects are defined as belowTo introduce the concept of scientific and planned rearing in the field of Angora rabbit wool production. To provide quality concentrate feed and ensuring its regular supply at denoted standards. To provide basic training in Angora rabbit rearing so that women and educated unemployed youth can take up this profession and traditional farmers can supplement their income. To create opportunities for employment and income generation in rural areas by developing wool based village and cottage industries. To follow integrated approach for development of integrated angora rabbit wool development programme to increase production and productivity of Angora wool and Angora woollen products. To involve various Govt. & Non Govt. Development agencies in the fied of Angora rabbit production, wool Processing and marketing under existing small scale, cottage & handloom set up. Implementing Agency: The Project will be implemented by the State Government Organization, Co-operative Societies/ Non-governmental Organization engaged in Angora Rabbit Development Programme in the concerned State. All the beneficiaries of the Project are to be encouraged to form one or more cooperative societies or are to be taken as member in existing co-operatives. The implementing Agency will implement the Project through the concerned Society. Components of the Project The project implementation will have the following components-: i) ii) iii) iv) Establishment of Mini Angora Rabbit Farms Common Facility for Angora Wool Processing & Training Research & Development Strengthening of Angora Rabbit Germplasm Centre 1. Establishment of Mini Angora Farmsi) Const. of Shed Since angora is a costly fibre, each rabbit has to be housed in rust proof cages preferably under shed system to avoid any loss due to improper management. This requires higher investment on quality germplasm, cages, housing system & other daily routine management practices to establish and run a farm and to get good returns. The high cost of inputs also discourages the reares to provide the required inputs leading to slow D:\116106756.doc 2 progress, poor reproductive efficiency in the flock, high mortality rate, low wool production and uncertain/poor returns. Assistance for const. of shed for 50 animals to the beneficiaries attaining the target of 50 angora rabbits after completion of one yr. Period will be provided @ Rs.10, 000/- i.e. 50% of the shed cost. Total cost for the cons. of shed will be Rs.20,000 /-. The Board will provide 50 % of total cost of shed & remaining will be contributed by beneficiaries itself. ii) Training to farmers- training will be the essential part of the project. Training to the rural farmers will be organized at GARSA, Kullu to sensitive farmers to variety of rabbit related income generating activities so that they can gain knowledge about latest information in the field of rabbit husbandry as well as information about the breed, common diseases & their control through vaccination, deworming & fodder production etc. the training will be aimed to encourage rural farmers to adopt rabbit farming as a profitable venture. After providing training to selected beneficiaries the Board will give foundation stock to them for rearing. iii) Supply of foundation stocks Since rearing of angoras is mainly hill enterprise, the topographic conditions, permits scattered and small units, which are difficult to supervise on regular basis under the present set up of ongoing programmes. This results in closing up of the units in the primary stage. The farmer is unable to get the necessary assistance in case of problems faced by him in day-to-day management. Therefore under this activity each selected families will be provided a foundation stock of 12 Angora rabbit (4 Male + 8 Female). A committee of technical officers will select the foundation stock of their choice from govt. farm/private breeders. This component has been taken with the view to improve the production of Angora rabbit hairs of specified character undertaking a continuous programme of selection of animals with desired parameters. Supply of such selected animals has to be ensured to the farmers, so that the production remains optimum. A provision of Rs.12, 000 /- is kept for one unit of 12 rabbits in the Project. It was envisaged that a unit up to 50 rabbits could be reared in a small low cost shed. It is assumed that an average family will start with 4 male + 8 female; and the unit will grow to a size of 24 by the end of the 1st year and to a size of 50 in the 2nd year and will be maintained. iv) Supply of cages The CWDB will provide two a unit of 24 cages to each family assuming that a unit of 12 rabbits will increase to 50 rabbits in two years. Under the project, a provision of Rs. 4000/- per unit is kept for supply of cages for the rabbits to the beneficiaries. v) Supply of Medical kit Rabbit is an animal, which liable to contract numerous disease. There is need to develop management practices in which possibility of diseases introduction is minimized. Accordingly a provision of Rs. 500/- per beneficiaries has been made in the Project. D:\116106756.doc 3 vi) Supply of feed The present system of rabbit rearing requires availability of most balanced feed. The Board will provide fund of Rs. 6500/- per unit for 2 year for initial parent stock of 12 rabbits & for remaining, farmer will arrange from his own resources. v) Provision of bageshwari Charkas & looms It is envisaged that several if not all rabbit rearing families would have the capability, and want to spin part of their own wool, both to meet their own requirements and to absorb the value addition into their earnings. Therefore, it would be essential to incorporate the concept of processing 25 to 30 percent of the wool produced in every household into yarn as well as finished products. The Board will provide Rs.6000/- for purchasing of one Charka & manual card to beneficiaries. 2. Common Facility cum training Centres The Board will provide financial assistance as subsidy @ 50% of the total cost of equipments/machines required by the organization, however maximum limit of subsidy amount will be Rs. 3.00 Lacs only in each case. If state Govt. Deptt. /Organization it self interested to set up CFC, then 100% financial assistance may be given for equipments /machineries. If an organization already having sufficient infrastructure to run the center, assistance will be given for training part only. a) TrainingSelected organization will provide training for a batch of 10 persons for three months in spinning, weaving & designing of wool and woolen products. Trainees will be selected from the nearby areas of the centres. The Board will provide stipend @ Rs. 60/- per day to the each trainee for three months. The Board will also provide assistance @ Rs. 5000/- per month as honorarium for keeping an instructor to train the selected persons. The raw material will be contributed by the organization that will run the CFC. Preference may be given to those organizations, which are already been engaged in processing of wool & Woolens. b) Support Services for establishing processing unitsThe Board will also provide financial assistance for distributing looms and charkas to the selected trained persons so that they can able to spin & weave wool and woolens and generate income from this profession. This facility will be created at the premises of Common Facility Centre to undertake job work by trained persons provided by the implementing agency of these items will be handed over to the beneficiaries if they desired so. c) Support services for product development, Design Development and product diversificationQuality product and its designating is essential to compete in national and international market. However the technical know-how for quality products manufacture and designing is lacking for this high priced fibre. Production of quality angora blended yarn; vegetable dyeing of yarns and product designing are the fields, which need serious intervention. D:\116106756.doc 4 The Board will support the selected organization for providing services of reputed organizations like NIFT, NID, TRA’s, CSWRI & WRA etc. to give technical know how for product development and diversification to the center & trainees. d) Marketing Support The CWDB will also provide free stalls, transport expenses to the selected organizations to exhibit and sale their products in Woollen expo organized by the Board at different places during winter season. 3 Research and Development- Looking at the inadequate availability of raw material, low productivity of the looms, and poor skills or the weavers in weaving techniques, the scheme will encourage R&D activities on diverse connected issues, eg. Fabrication of machines, blending and processing of angora wool, dyeing and designing of Woollen products made of angora etc. For this purpose, Research Institutes Universities/TRAs, etc. will be provided assistance for R&D Projects. 4 Strengthening of Angora Rabbit Germplasm Centre- Rabbit has fast multiplication rate with a gestation period of only 30-32 days. Effective planning is required to control in breeding problem. In breeding decline the reproductive and production performance, causes poor growth rate, genetic & congenital abnormalities. Average wool production in the country varies between 600 to 700 Gms. per animal this is due to non-availability of high wool yielding germplasm of Angora rabbits for up gradation of the existing GPC. There is a need to strengthen the existing centers by providing quality germplasm either by import from different country or make available at domestic level so that parent stock can be kept there and the kid produced can be made available to the beneficiaries. The project proposes to strengthen existing GPCs and state rabbit farms to upgrade technical know how. For this purpose high yielding Angora rabbits of 8-10 sire lines will be procured from abroad as well as from domestic sources. This will be a continuous process to grow & maintain the high quality Germplasm for further distribution to farmers. Physical and Financial targets under the scheme is as followsEstimated Projection of Rabbit Population and Angora Wool Production under the Project S. Particulars No. 1. No. of Families to be benefited 2. Population of Rabbit in the ambit 3. Total Angora Wool production 0.750 Kg. per animal, per year. D:\116106756.doc 1st Year 40 2nd Year 4th Year 100 5th year Total 160 3rd Year 100 - 400 1000 6000 12500 17500 20000 20000 750 4500 9375 15000 42750 13125 5 4. Approximate market value of Angora Wool out put @ Rs. 900/- per Kg. (Rs. in Lakhs) 6.75 40.50 84.37 118.12 135.00 384.74 Component-wise Indicative Financial Implications for ‘Angora Wool Development Programme’ during the 11th Five Year Plan for Rs. 446 lakhs crores is as under: (Rs. in lakhs) S.N I Activity Unit cost (for 2 2007-08 year project) 2009-10 2008-09 2010-11 2011-12 Establishment of Angora Production Units D:\116106756.doc 6 Total No. of Families to be covered a) b) c) Assistance for construction of low cost Shed to attaining the target of 50 rabbits after completion of one year the farmers.(50% of cost of shed) Supply of foundation stock (4 male + 8 female)@ Rs. 1000/- per rabbit (1000X12) Supply of cages (24 cages for one unit)@Rs.4000/- per unit 40 160 100 100 400 0.100 4.000 16.00 10.000 10.000 - 40.000 0.120 4.80 19.20 12.000 12.000 - 48.000 0.080 1.60 8.00 10.40 8.000 4.000 32.000 d) Supply of medical kit @ Rs.500/- to each beneficiary 0.005 0.200 0.80 0.500 0.500 - 2.000 e) Supply of feed (150gm/rabbit/day) 12X0.150X365=6.57@Rs.1000 per Quintal (Rs.550 per rabbit per year 0.130 2.600 13.00 16.90 13.000 6.500 52.000 f) Provision of bageshwari Charkha & manual carding machine for spinning of Angora Wool at household level by beneficiary @Rs.6000/- 0.060 - 2.400 9.600 6.000 6.000 24.000 Total ( a to f ) 0.495 13.2 59.40 59.4 49.5 16.5 198 0.025 0.66 2.97 2.97 2.45 0.825 9.85 0.520 13.86 62.37 62.37 51.95 17.32 207.90 g) Overhead expenses @ 5% of Total Cost of the project Total (a+b+c+d+e+f+g) D:\116106756.doc 7 S.N Activity II Setting up of Common Facility – Cum – Training Centre:- 2009-10 2010-11 2011-12 Total 1 8 5 5 5 24 3 3.00 24.00 15.00 15.00 15.00 72.00 Support for establishment Processing Units (Looms & b) Charkas) 7000/- per set of loom & charka 1.4 1.40 11.20 7.00 7.00 7.00 33.60 Support for product development, c) design development & product diversification. 1 1.00 8.00 5.00 5.00 5.00 24.00 2.16 17.28 10.80 10.80 10.80 51.84 0.6 0.60 4.80 3.00 3.00 3.00 14.40 8.16 8.16 65.28 40.80 40.80 40.80 195.84 0.26 0.26 2.08 1.30 1.30 1.30 6.24 8.42 8.42 67.36 42.10 42.10 42.10 202.08 R&D activities on divers connected issues like fabrication of machines, blending and processing of angora wool and designing of Woollen products made on angora etc. - 14 5 - - 19 Strengthening of Existing Germplasm Centres (GPC) - 5.12 4 4 4 17.12 Stipend to trainees (10 persons for 3 months @ Rs. 60/- per day) 60X30X3X10=54000 Honorarium to Instructor @ Rs. e) 5000/- per month Total (a+b+c+d+e) Administrative Overhead to f) implementing agency (approx. 10% of training part only i.e. (b) to (e ). IV 2008-09 Support for setting up Processing Facility – Blending / Carding / a) Spinning /Dyeing / & Finishing (subsidy 50%, maximum Rs. 3.00 Lakhs) d) III Unit cost (for 2 2007-08 year project) Sub total II (a+b+c+d+e+f) Research& Development: - 2.16 GRAND TOTAL ( I to IV ) 22.28 148.85 D:\116106756.doc 113.47 98.05 63.40 446.05 8