PERSONAL PROTECTIVE EQUIPMENT (Part `A` & `B`)

advertisement

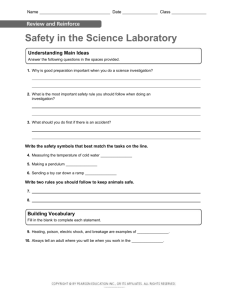

PERSONAL PROTECTIVE EQUIPMENT (Part ‘A’ & ‘B’) California Occupational Safety and Health Administration (Cal/OSHA) requires all employees to wear the right personal protective equipment (PPE) whenever you work in a potentially hazardous situation. The employer is required to purchase and provide the right PPE for your job (at no cost to you) and trains you in the use of that equipment. PART “A” HEAD PROTECTION: Your head is exposed to injury every day on the job. You can avoid most head injuries if you wear the right headgear. Injury Impact to head Electric shock Splashes and spills Cause of injury Falling or flying objects Electric current Liquids, caustics, metals Result of injury Neck sprain, concussion, fracture Shock and burns Skin or eye irritation, burns How Hard Hats Work Safety headgear softens any blow to the head. The hard shell resists and deflects the blow. It distributes the impact over a large area. The hat suspension acts as a shock absorber. Even is the hat dents or shatters, it still takes some force out of the blow. All hard hats must meet the test required of ANSI standard Z89.1. This may include protection against electric shock when working near electrical lines, equipment and facilities. The hat shields your scalp, face, neck and shoulders against splashes or spills. Some hard hats are made so you can ass other protection, such as goggles, hearing protection, face shields and hoods. Your Checklist: Make sure your hat fits right. There should be approximately 1” between the harness and the shell so air can circulate and keep your scalp cool. If your hat is too loose, it will fall off when you bend over. Too tight and it may cause headaches. Wear a color-coded hat if you need identification. Don’t paint or scratch your hard hat to identify it. Add light-attracting tape to your hat if you work at night or in the darkness. Inspect your hard hat every day. Look for gouges and cracks. Check for frayed or broken sweatbands and straps. The style of headgear you select should be adequate for the work you do. See your EH&S department for assistance. EYE PROTECTION:If employees are exposed to potentially dangerous chemicals or flying particles, they need eye protection. Eye protection is available as safety glasses, goggles and additional protection of face shield. Safety glasses or goggles cover the front and sides of the eyes and protect against flying objects such as particles and dust. They can be tinted, anti-fog or have prescription lenses. When wearing goggles, check that they fit your face snugly, sealing the entire eye area. Make sure that you are wearing the correct goggles for the job. Some goggles are designed for particles and dust the other type is designed for chemicals. Never use goggles designed for particles and dust when working with chemicals. Face shields can be worn with safety glasses or goggles they protect against splashes to the face. If you are exposed to injurious light rays or other radiant energy, you will need goggles, helmets or face shields equipped with special filters. Proscription glasses and contact lenses will not protect your eyes. In fact, wearing contact lenses alone can even be more hazardous because dust or material may lodge under lenses, causing eye injury. HEARING PROTECTION: If noise levels are high (85dB or above) in your workplace, you should wear hearing protection. Excessive noise not only slowly and permanently damages your hearing, but it also adds to your fatigue and stress. These effects lead to accidents and hazardous mistakes. The goal of hearing protection is to reduce your exposure to harmful noise while at the same time allowing you to hear machine warnings and voices. Hearing protection falls into two broad categories earplugs and earmuffs. Earplugs: Earplugs are made of light and comfortable material and fit in the ear itself. They range from foam disposable cylinders to customized molded plugs. To insert foam earplugs, roll the plug between your thumb and forefinger until it is completely compressed. With the opposite hand, pull the outer ear out and up, and then insert the plug as far into your ear as possible, but not too far. A comfortable fit is all you need. Earmuffs: Earmuffs are cushioned and cupped ear coverings attached to a headband or your hard hat. Earmuffs come in a wide variety of sizes and models. They are made specifically for certain noise levels and work environments. When using earmuffs, be sure you have a perfect seal between the muff and the skin around your ears. Hair, jewelry and glasses can interfere with this protective seal. In areas with extreme noise levels, you may have to wear both earplugs and earmuffs. Check with your EH&S department to see what hearing protection is required. PART “B” HAND PROTECTION: Gloves are used to protect employee’s hands from burns, cuts, chemicals and to get a better grip on the items. Employees should wear gloves if their work exposes them to temperature extremes or harmful substances that can be absorbed through the skin. You should also wear gloves to prevent severe cuts, lacerations, abrasions, punctures, chemical burns and thermal burns. No single glove type protects you against every hand hazard. As with most PPE, supervisors and employees must chose the right protection for the job. There are four glove classifications: General purpose – made of either leather or cotton, these gloves offer minor protection from abrasions, cuts, punctures, snags and minor temperature variations. Leather a heavier material, gives more protection from cuts and heat. Cut resistant – made of wire metal mesh, these gloves contain Kevlar, Aramid or Spectra yarn to reinforce their cut resistance. Special purpose – manufactured according to the jobs for which they are needed. For example, firefighters and smelter workers use specially insulated gloves designed for use in extreme heat. Chemical resistant – prevents contact with and absorption of hazardous chemicals into your body. Because these gloves need to be non-porous, they are usually made of many different materials such as Nitrile, neoprene, butyl rubber or natural rubber. Before putting on your gloves, inspect them for rips, holes, or anything that may weaken their effectiveness. Do not try and repair damaged gloves, always dispose of them and get a new pair. Be sure gloves fit well. A glove too big or small could weaken protection. FOOT PROTECTION Footwear should meet the needs of the job. That way if an accident occurs, their feet are given extra protection. Many workplace foot injuries are caused by small objects no heavier than seven pounds and dropped from a height less then four feet. Most workers who suffer foot injury fail to wear safety shoes or boots. Protective footwear guards your feet from impact and crushing injuries. Like other safety equipment, the type of protective footwear you need depends on your job. Examples of foot protection need to avoid workplace hazards: If you work with packages, objects, part or heavy tools, wear sturdy, protective footwear with puncture resistant soles. If you work in areas with potential for sharp objects to penetrate your feet, wear shoes with puncture resistant soles. If your workplace has exposed electrical circuits or wires, wear non-conductive shoes. If you come into contact with chemicals, wear specially coated footwear that will protect you from the hazardous chemicals. Remember: If you are not sure which protective footwear is best for your workplace, ask your supervisor. RESPIRATORY PROTESTION: At least three million American workers wear respirators on the job every day. Yet workers suffer 66,500 sever exposures to airborne hazardous substances each year. These exposures can lead to: Skin irritation, Loss of vision, Permanent respiratory damage, Cancer, Heart disease or other chronic illnesses. To prevent these illnesses and injuries, Cal/ OSHA updated the general industry respiratory protection standard, which applies to all employees. Training is a critical part of respirator use. Before an employee is allowed to wear a respirator on the job, they must be fully trained and re-trained as needed. This training can protect you when you work in hazardous atmospheres. Hazardous Atmospheres: Hazardous atmospheres fall into two basic categories – Oxygen deficient and Contaminated. The atmosphere can be contaminated by: Dust, Sprays, Fumes, Vapors, Smoke and Harmful gases. When engineering controls are not feasible or are being installed, you may be required to wear a respirator. (Engineering controls are fans, exhaust hoods etc..) The respirator the employee wears must be applicable and suitable to the type of hazard that the employee faces. There are two basic types of respirators: Air-purifying – these respirators come in three basic types, Particulate removing, Vapor and gas removing or a combination of the two. Atmosphere supplying – are Self contained breathing apparatus (SCUB) and Air-line respirators. Part “A” QUIZ answers 1.True 2.Ture 3.False 4.False 5.Flase 6.True 7.True Part “B” QUIZ answers 1. 2. 3. 4. 5. 6. 7. False True True True True True False

![Lab Safety Notes [8/31/2015]](http://s3.studylib.net/store/data/006888939_1-6bb01d0df93e4bd7262a0fecabf05a75-300x300.png)