GENETIC ALGORITHM FOR THE OPTIMIZATION OF SUPPLY

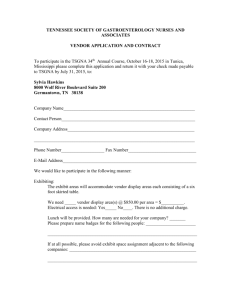

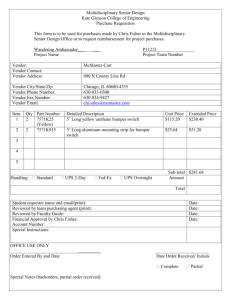

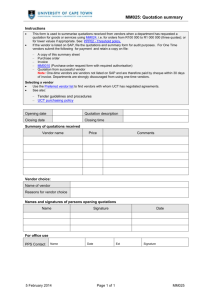

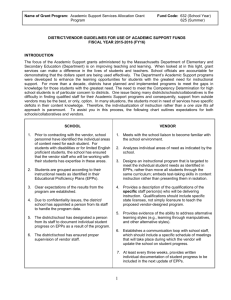

advertisement

GENETIC ALGORITHM FOR THE OPTIMIZATION OF SUPPLY CHAIN MANAGEMENT Dr. M. Senthil Mr. M. Venkatesh Prabu Dr. K.S. Chandrasekar Abstract Supply chain management (SCM) deals with the total flow of materials from vendors to the ultimate users. Traditionally SCM operated independently in the marketing, distribution, planning, manufacturing and purchasing. Now, the SCM is a strategy through which integration can be achieved .In this work, various optimization problems in SCM such as vendor selection, and transportation are identified and described. There are many modern optimization techniques are available for solving different supply chain optimization problems. Not all these techniques are robust and each technique is suitable for solving a particular type of supply chain optimization problem. Genetic Algorithm (GA) is an adaptive search and optimization that uses the principle of natural genetics and natural selection. Genetic Algorithms are very different from traditional search and optimization methods uses in different manufacturing problems in organizations. Because of its simplicity, ease of operation, minimum requirement and global perspectives, it is gaining popularity in the manufacturing arena. At this research study, uses the genetic Algorithm for optimization of the Supply Chain Management. This paper also focuses its attention on the implementation strategies which uses coding technique, reproduction, cross over, mutation and Fuzzy logic. Introduction: In today global market, managing the entire supply chain becomes a key factor for the successful business .In the early 1990’s the phrase Supply Chain Management (SCM) came into use. SCM is a process of integrating / utilizing suppliers, manufacturers, warehouses and Retailers, so that goods are produced and delivered at the right quantity and at the Right time, while minimum costs as well as satisfying customer requirements. In today’s highly competitive market manufacturers face the challenge of reducing manufacturing Cycle Time, Delivery Lead time and Inventory reduction .However ever organization has its own objectives and its own way of decision making processes. Typical supply chain contains a number of organization beginnings with suppliers who provide Raw materials to manufactured goods in the warehouses, and then they send them to whole sales/ distribution centers Supply Chain optimization is forfeited in favor of inter departmental performance objective and priorities. New collaborative model is coming together of expertise, Resources, Intelligence & Systems that will create new dimensions in SCM and Optimization. In this paper we deal with the Vendor selection and Transportation . Any improvement in the faster supply of raw materials and finished goods and reduction of production and material handling, cost would imply trade offs. This paper discuss about the procedure for how to optimize the above said parameters are optimized using GA for achieving the above said goals of SCM. Vendor Selection Management: In the fierce and severe competitive world the company lies to a greater extent to the selection of a sound vendor. It makes for smoother operation of the purchasing department. An appropriate selection of supplier can provide a manufacturing firm with a competitive advantage.Purchasing is often the initial and primary contact for the firm’s external vendors. Many different methods of selecting a vendor have been identified in the research. The following are the factors determine the vendors: 1. Right Partner: Pre requisites for the successful vendor - Characteristics of good vendors - Find the quantified vendors - To look for potential vendors - Characteristics of effective relationship. 2. The Right contract: Types of contracts based on fixed Price, Cost, Time and materials. 3. Right contract Agreement: Types of Master Agreement Specific requirement of master Agreement Timing consideration 4. Right Attitude: Performance Management Performance of the Plan Effectively Managing open communication Management Change Handling the Disputes Apart from the 4 key activities of an effective vendor selection process, Knowledge of vendor selection Management Methodology is essential in a supply chain management. Vendors have promoted successive waves of new supply chain management theories and technology solutions which have held out the promise of greater efficiency, Lower cost Less Latency, Flexibility and Less rejection. Supply Chain Management is about getting the Right Product to the Right Place at Right Time in the Right Volume and the Right Price. The problems raised in the vendor selection process is taken for this and analyzed through optimization techniques. Transportation: One central problems of SCM is the co-ordination of product & material flows between Locations .A typical problem involves bringing products located at a central facility to geographically dispersed facilities at minimum cost , methods for dealing with the important issues in transportation as mode selection, carrier routing , vehicle scheduling and shipment consolidations. Well known problems in transportation is the Vehicle scheduling and routing .An efficient solution is one that enables goods to be delivered When & Where required at least cost subject to legal & political constraints? Problem Description In this work there are two functional areas of SCM that is Vendor selection and transportation have been taken for analysis. Vendor Selection Problem (VSP) The proposed VSP is a three criteria decision making problems.They are cost of Goods , Percentage of Rejection and Late Delivery Time.Two assumtions are made inorder to optimize the above said criteria of the VSP , That is only one item is purchased from one vendor and no shortage of the item is allowed for any of the vendor The following is the input parameters consider for the optimization of this VSP. Agreegate Demand of the item (D) No. of vendors for selection (n) Price of per unit item (Ci) Percentage of Rejection (Ri) Percentage of Late Delivery(Li) Upper Limit of Quantity available for vendor i (Ui) Vendor quota (fi) Vendor Rating(ri) Budget constraint (Bi) Objective Function : The objective function of the VSP are Minimization of cost of all items,Min. the Net number of Rejected items and min. the Late delivery. The multi objective VSP have to be solved with the satisfaction of the following constraints, Demand Maxim um capacity of vendor vendor quota Budget of vendors The following is the multi objective VSP is , n Min Z 1 = Ci(xi) i =1 n Min Z 2 = Ri(xi) i =1 n Min Z 3 = Li(xi) i =1 subject to , n xi<=D i =1 n fi>=F i =1 n ri>=P i =1 Ci (xi)<=Bi where xi- order quantity for the vendor i The optimization procedure using GA for the vendor selection is discussed in thechapter of implementation procedure of GA . Transportation problem: In this transportation there are six input parameter are identified for optimization with three constraints.The input parameters are Distance , quantity of goods, delivery time , place , vehicle schedule and vehicle route. and the constraints are Number of vehicles , manpower and time.The objective function is to minimise the optimal route with min. transportation cost.The developement of mathematical model for the objective function is similar to the above VSP. Genetic Algorithm: GA is an adaptive search and optimization algorithm based on mechanics of natural selection and are versatile in their applications. History of GA: First GA was pioneered by John Holland in the 60’s .GA has been widely studied experimented and applied in many fields in engineering and Management. Many of the real world problems involved in finding optimal parameters, which might prove difficult for traditional methods but ideal for GA’s .Most users come to GA’s looking for a problem solver, because, GA s as challenging technical Puzzle GA s as basis for competent machine learning. GA s as computational models of innovation and creativity. GA s as computational model for other innovating systems. GA s as guiding philosophy. The main characteristics are: GA s work with the coding of the parameter set, not the parameter themselves. GA s search from a population of points not from a single point GA s use pay off ( Objective function ) information , into derivatives or other Auxiliary knowledge GA s use probabilitistic transition rules not deterministic rules. GA s is based on the principle of the survival of the fittest. GA is a search and optimization technique operated on the principle of the “Survival of the fittest “ where weak individuals die before reproducing while stronger often survive and bear many off-spring and breed children , which often inherit the qualities that are in most cases superior to their parents . GA begins with a population of string created randomly. There after, each string in the population is evaluated. The population then operated by three main operators, reproduction, crossover and mutation to create a better population. The population is further evaluated and tested for termination. If the termination criteria are met, the population is again operated by the above three operators and evaluated. This procedure is continued until the termination criteria are met. One cycle of these operators and the evaluation procedures is known as a generation is GA terminology. Fuzzy Logic: It is a superset of the conventional Boolean logic that has been extended to the handle the concept of partial truth. The truth values between completely true and completely false. The fuzzy sets the transition from membership to non membership in sets is gradual and not abrupt Fuzzy systems pioneered by Izadeh in the 1960’s basically deal with how beings handle imprecise and uncertain information. AS static / Dynamic System which makes use of fuzzy sets or fuzzy logic of the corresponding mathematical frame work is called a fuzzy system. Implementation Procedure Using GA and Fuzzy Logic Implementation of Genetic Algorithm: Coding technique: In order to solve the multi objective problems in SCM, the values are presented as binary digits. The length of the string is usually determined according to the desired solution accuracy. Reproduction: Reproduction is usually the first operator applied on a population. Reproduction selects good string in a population and forms a mating pool. In reproduction the above average strings are picked from the current population and their multiple copies are inserted in the mating pool in a probabilistic manner. In Roulette Wheel selection using the fitness value of all strings, the probability of selecting a string can be calculated. There after the cumulative probability of each string being copied can be calculated by adding the individual probabilities from the top of the list. The Roulette Wheel concept can be simulated by realizing that the i-th string in the population represents the cumulative probability values from Pi-1 to pi. The first string represents the cumulative probability of any string lies between 0 to 1, in order to choose n strings, n random numbers between 0 to 1 are created at random. Thus a string that represents the chosen random number in the cumulative probability range for the string is copied to the mating pool. This way the string with a higher fitness value will represent a larger range in the cumulative probability values and therefore has a probability into the mating pool. Cross Over: The string in the mating pool formed after reproduction is used in the cross over operation. In the single point cross over two strings are selected at random and crossed at random site. Since mating pool contains strings at random, a pair of string is picked from the top of the list. When two strings are chosen for cross over, the probability of cross over determines whether a crossover is desired or not. If desired, cross over is performed: otherwise the strings are directly placed in the intermediate population for subsequent genetic operation. The next step is to find a crossover site at a random. Creating a random number between 1 & k-1 where K is the length of chromosome. Mutation: The mutation changes the bit 1 to 0 and vice versa. The bit wise mutation is performed bit by bit by flipping a coin with the required probability of mutation. If at any bit the out come is true then the bit is altered: otherwise the bit is kept unchanged. Fuzzy Logic: In order to handle the uncertainties with the objective function, simple Fuzzy Logic is used for evaluation. It is based on the extension of the classical definition of a set with certain degree of membership. Using Bellman & Zadech ‘s ( 1970) approach a Fuzzy decision is a fuzzy set and is obtained by the intersection of all the fuzzy sets representing the fuzzy objectives and fuzzy constraints. Conclusion: Multi objective supply chain management functions like vendor selen\ction and Transportation are identified for optimization . The optimization procedure for the above said two functions have been discussed detail using GA .Inorder to consider the uncertainties arises in these problems a simple Fuzzy logic approach is proposed to find the optimal solutions.By using this methodology in SCM the following can be obtained in the VSP:. Minimise the cost Minimise the Rejection Minimise the delivery time and Minimise the distance travelled Minimise the cost for Transportation problems of Supply Chain Management. can be obtained in the transportation ****************