Solvothermal Synthesis of Polyazomethine Microspheres

advertisement

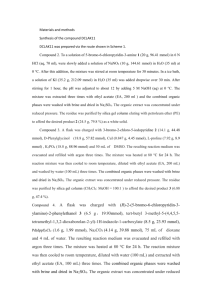

Supporting Information Solvothermal Synthesis of Polyazomethine Microspheres by Pickering Emulsion Templates and their Dynamic Imine Chemistry Enabled Transformation into Complex Microtubes and Anisotropic Hollow Spheres Zihua Chen, Yi Jiang, Lu Chen, Wei Huang, Xiang Li, Xiaojuan Li, and Xikui Liu * S1. Synthesis of 2, 4, 6-tris(4-aminophenyl)pyridine ,TAPP 2,4,6-tris(4-aminophenyl)pyridine(TAPP) was synthesised according to the previously reported procedure[S1]. In a round-bottomed flask (250mL) equipped with a reflux condenser, a mixture of pnitrobenzaldehyde (7.5 g, 0.05 mol), p-nitroacetophenone(16.5 g, 0.10 mol), ammonium acetate(60.0 g), and glacial acetic acid (150mL) were refluxed for 6 h. After cooled to room temperature, the mixture was separated by filtered and washed first with acetic acid (50%) and then with cold ethanol. The crude product was directed used without further treatment. To the solution of the obtained nitro compounds(6g, 5.99mmol) in ethanol (120mL), hydrazine monohydrate (10.00g,excess) and Pd/C(1.0g, 5wt%) were added and refluxed for 5 hr. The mixture was hot filtered and washed with ethanol. The combined filtrates was evaporated and then the crude product was recrystallized from ethanol to get pale yellow crystals of 2,4,6-tris(4-aminophenyl)pyridine. Yield: 56%. Mp.250 ºC. FTIR (KBr, cm-1): 3402, 3304, 3208, 1600, 1540. 1H NMR (DMSO, 400MHz, ppm): δ 5.38 (s, 4H), 5.45 (s, 2H), 6.66-6.68(d, 4H), 6.70(d, 2H),7.67(d,2H),7.68(d,2H),7.96-7.98(d, 4H). Scheme S1. Synthesis of 2,4,6-tris(4-aminophenyl)pyridine S2. Synthesis of 5, 10, 15, 20-Tetrakis(4-aminophenyl)-21H,23H-porphine,TAPR 5,10,15,20-tetrakis(4-nitrophenyl)-21H,23H-porphine was synthesised according to the previously reported procedure[S2] with a little modified. 4-nitrobenzaldehydewas(10.0 g,66mmol) dissolved in 60 mL nitrobenzene, to which 4.7ml (68mmol) pyrrole was added. Then the above solution was dropped into refluxing nitrobenzene and lactic acid mixed solutions (110ml,v/v=1:1) during 30 min, and refluxing for another 3 hr. The obtained mixtures were cooled to 60 ºC and 80mL methanol added to give a precipitate which was collected by filtration, washed with distilled water and methanol, and dried under vacuum. The resulting powder was dissolved in 100 mL pyridine and was refluxed for 1.5 h. After cooling, the precipitate was collected by filtration and washed with acetone to give 5,10,15,20-tetrakis(4-nitrophenyl)-21H,23H-porphine as a purple crystal in 15% yield. The product(2.0g, 2.5mmol) was dissolved in 80mL concentrated hydrochloric acid at room temperature, to which was added SnCl2·2H2O(9.0g, 40mmol). The resulting mixture was stirred at room temperature for 3hr and then 80 ºC for 1hr. After cooled to room temperature the solution was neutralization with NH3·H2O, the resulting gray product was collected by filtration and dried under vacuum. The dried products were extracted by the Soxhlet extractor with 250mL chloroform. Rotary evaporation of the solution followed by drying under vacuum yielded TAPR as a purple crystal. Yield: 85%. Mp > 300 ºC, IR (KBr, cm-1): 3445, 3367, 3309, 3023, 1615, 1509, 1465, 1349, 1281, 803, 739. 1 H NMR (CDCl3, 400MHz, ppm): δ -2.73 (s, 2H), 4.03 (s, 8H), 7.00(m, 8H), 8.0 (m, 8H), 8.90 (s, 8H). Scheme S2. Synthesis of 5,10,15,20-Tetrakis(4-aminophenyl)-21H,23H-porphine S3.The synthesis of tetra(4-aminophenyl)methane, TAPM Tetra(4-aminophenyl)methane was synthesised according to the previously reported procedure[S3] with a little modified. To tetra(phenyl)methane (10g, 31.3mmol) 50mL of fuming nitric was added in portions at 0 ºC with vigorous stirring. Then to this mixture 16mL of acetic anhydride and 32ml of glacial acetic acid were added dropped and stirred for about 60 minutes. Finally the reaction mixture was filtered and washed with acetic acid and methanol. After filtration, the crude product was recrystallized with THF to get yellow crystals of tetra(p-nirtophenyl)methane. In a three necked round bottomed flask, tetra(4-nitrophenyl)methane (5g, 10mmol), hydrazine monohydrate (20.00g ,excess) and Pd/C(2g, 5%) were suspended in ethanol (150mL) and the mixture was refluxed for about 8 hours. The mixture was hot filtered and washed with THF. The combined filtrates was evaporated and the residue was washed with ethanol and dried to get white crystals of tetra(4-aminophenyl)methane. Yield: 95%. IR (KBr, cm-1): 3394,3170,3062,3023,1610,1580,1508,1430,1340,1271,1184, 1140,1097,1015,861,832, 784,718, 581,518. 1H NMR (DMSO, 400MHz, ppm): δ 4.85(s, 8H), 6.38 (d, 8H), 6.67(d, 8H). Scheme S3. Synthesis of tetra(4-aminophenyl)methane S4. Preparation of 2,4,6-tris(4-aminophenyl)pyridine-based polyazomethine anisotropic particles 2,4,6-tris(4-aminophenyl)pyridine(140.8 mg,0.40 mmol) and 1,4-terephthalaldehyde(80.4 mg, 0.60 mmol) were placed in a Teflon-lined autoclave. Then, 5.0 ml of anhydrous dioxane and 5.0 ml mesitylene were added. The autoclave was immersed in an ultrasonic bath for 30min; following sonication 1.0 ml of 6 M aqueous acetic acid was added. The reaction was heated at 120 ºC for 72 h yielding a yellow colored solid at the bottom of the autoclave which was isolated by centrifugation and washed with dioxane and ethanol. The obtained powder was dried at 60 ºC under vacuum. Yield 182.3mg, 86.7% based on TAPP. Scheme S4. Preparation of polyazomethine-based Anisotropic Particles S5. Preparation of 5,10,15,20-Tetrakis(4-aminophenyl)-21H,23H-porphine-based polyazomethine Anisotropic Particles 5,10,15,20-Tetrakis(4-aminophenyl)-21H,23H-porphine ( 135 mg , 0.20 mmol) and 1,4- terephthalaldehyde(53.6 mg, 0.40 mmol) were placed in an autoclave. Then, 25.0 ml of anhydrous dioxane and 25.0 ml mesitylene were added. The autoclave was immersed in an ultrasonic bath for 30min; following sonication 5.0 ml of 6 M aqueous acetic acid was added. The reaction was heated at 180 ºC for 72 h yielding a purple colored solid at the bottom of the autoclave which was isolated by centrifugation and washed with dioxane and ethanol. The obtained powder was dried at 60 ºC under vacuum. Yield 139 mg, 76.6% based on TAPR. Scheme S5. Preparation of polyazomethine-based Anisotropic Particles S6. Preparation of tetra(4-aminophenyl)methane -based polyazomethine anisotropic particles Tetra(4-aminophenyl)methane(76 mg ,0.20 mmol) and 1,4-terephthalaldehyde(53.6 mg, 0.40 mmol) were placed in a Teflon-lined autoclave. Then, 5.0 ml of anhydrous dioxane and 5.0 ml mesitylene were added. The autoclave was immersed in an ultrasonic bath for 30min; following sonication 1.0 ml of 6 M aqueous acetic acid was added. The reaction was heated at 120 ºC for 72 h yielding a yellow colored solid at the bottom of the autoclave which was isolated by centrifugation and washed with dioxane and ethanol. The obtained powder was dried at 60 ºC under vacuum. Yield 90.2 mg, 73.7% based on TAPM. Scheme S6. Preparation of polyazomethine-based Anisotropic Particles S7. Preparation of hollow spheres and their transformation into microtubes A typical process is as follow: TAPP (140.8 mg, 0.40 mmol) and TPA (80.4 mg, 0.60 mmol) were placed in a Teflon-lined autoclave contaning 2.5 ml of anhydrous dioxane and 7.5 ml mesitylene, after sonication for 30min, 1.0 ml of 6 M aqueous acetic acid was added. It was then transferred into an oven and reacted at designed temperatures for various times. Morphological transformation from hollow sphere to worm-like microtube and finally to microtube with smooth surface can be observed during the different stage of reaction. Figure S1. X-ray diffraction patterns of the polyazomethine particles at different time stages Transmittance(%) 3440 3377 4000 3500 3000 2500 2000 1500 1000 500 -1 Wavenumbers(cm ) Figure S2. FT-IR of the initial formed polyazomethine nanoparticles Transmittance(%) Figure S3. TEM of polyazomethine anisotropic particles before treated in a stronger acid solution. 4000 3000 2000 1000 Wavenumbers(cm-1) Figure S4. FT-IR of the York-shell structure anisotropic particles with cavitation region REFERENCE: [S1] Chen. W., Yan, W., Wu, S., Xu, Z., Yeung, W. K. & Yi, C. Preparation and Properties of Novel Triphenylpyridine-Containing Hyperbranched Polyimides Derived from 2,4,6-Tris(4aminophenyl)pyridine under Microwave Irradiation. Macromol. Chem. Phys. 211, 1803–1813 (2010). [S2] Yuasa, M., Oyaizu, K., Yamaguchi, A. & Kuwakado, M. Micellar Cobaltporphyrin Nanorods in Alcohols. J. Am. Chem. Soc. 126, 11128-11129 (2004). [S3] Wang, Z.G., Zhang, B. F., Sun, L., Jiao, C.L. & Liu, W.S. Microporous polyimide networks with large surface areas and their hydrogen storage properties. Chem. Commun. 46, 7730–7737 (2010).