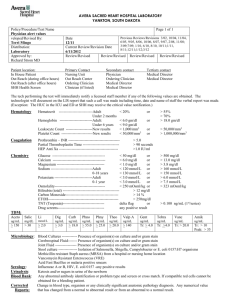

Materials and methods (docx 86K)

advertisement

Materials and methods Synthesis of the compound DCLAK11 DCLAK11 was prepared via the route shown in Scheme 1. Compound 2. To a solution of 5-bromo-6-chloropyridin-3-amine 1 (20 g, 96.41 mmol) in 6 N HCl (aq, 70 ml), were slowly added a solution of NaNO2 (10 g, 144.61 mmol) in H2O (35 ml) at 0 °C. After this addition, the mixture was stirred at room temperature for 30 minutes. In a ice bath, a solution of KI (35.2 g, 212.09 mmol) in H2O (35 ml) was added dropwise over 30 min. After stirring for 1 hour, the pH was adjusted to about 12 by adding 5 M NaOH (aq) at 0 °C. The mixture was extracted three times with ethyl acetate (EA, 200 ml ) and the combined organic phases were washed with brine and dried in Na2SO4. The organic extract was concentrated under reduced pressure. The residue was purified by silica gel column eluting with petroleum ether (PE) to afford the desired product 2 (24.5 g, 79.8 %) as a white solid. Compound 3. A flask was charged with 3-bromo-2-chloro-5-iodopyridine 2 (14.1 g, 44.48 mmol), D-Plenylglycinol (18.8 g, 57.82 mmol), CuI (0.847 g, 4.45 mmol), L-proline (7.92 g, 8.9 mmol) , K3PO4 (18.8 g, 88.96 mmol) and 50 mL of DMSO. The resulting reaction medium was evacuated and refilled with argon three times. The mixture was heated at 80 °C for 24 h. The reaction mixture was then cooled to room temperature, diluted with ethyl acetate (EA, 200 mL) and washed by water (100 mL) three times. The combined organic phases were washed with brine and dried in Na2SO4. The organic extract was concentrated under reduced pressure. The residue was purified by silica gel column (CH2Cl2: MeOH = 100:1 ) to afford the desired product 3 (6.88 g, 47.4 %). Compound 4. A flask was charged with (R)-2-(5-bromo-6-chloropyridin-3- ylamino)-2-phenylethanol 3 (6.5 g , 19.93mmol), tert-butyl 3-methyl-5-(4,4,5,5tetramethyl-1,3,2-dioxaborolan-2-yl)-1H-indazole-1-carboxylate (8.5 g, 23.93 mmol), Pd(dppf)2Cl2 (1.6 g, 1.99 mmol), Na2CO3 (4.14 g, 39.88 mmol), 75 mL of dioxane and 4 mL of water. The resulting reaction medium was evacuated and refilled with argon three times. The mixture was heated at 80 °C for 24 h. The reaction mixture was then cooled to room temperature, diluted with water (100 mL) and extracted with ethyl acetate (EA, 100 mL) three times. The combined organic phases were washed with brine and dried in Na2SO4. The organic extract was concentrated under reduced pressure. The crude product was dissolved in CH2Cl2 (20 mL), followed by the addition of 10 mL of trifluoroacetic acid (TFA). The reaction mixture was stirred at room temperature overnight. The mixture was concentrated under reduced pressure and diluted with CH2Cl2 (100 mL). The organic phase was washed with NaHCO3 (1M, 80 mL) three times and brine, and dried in Na2SO4. The organic extract was concentrated under reduced pressure. The residue was purified by silica gel column (EA: MeOH = 80:1) to afford the desired product 4 (3.54 g, 47.1%). DCLAK11. A microwave tube was charged with(R)-2-(6-chloro-5-(3-methyl-1H-indazol-5-yl)pyridin-3-ylamino)-2-phenylethanol 4 (1.0 g, 2.64 mmol), 5-chloro-2-hydroxyphenylboronic acid (0.68 g, 3.96 mmol), Pd(dppf)2Cl2 (193 mg, 0.264 mmol), K2CO3 (0.73 g, 5.28 mmol), 8 mL of dioxane and 0.4 mL of water. The resulting reaction medium was evacuated and refilled with argon three times. The mixture was heated by microwave at 120 °C for 2 h. The reaction mixture was then cooled to room temperature, diluted with water (50 mL) and extracted with CH2Cl2(50 mL) three times. The organic phases were washed with brine and dried in Na2SO4. The organic extract was concentrated under reduced pressure. The residue was purified by silica gel column (CH2Cl2: MeOH = 30:1) to afford the desired product DCLAK11 (561 mg, 45.1%) as a yellow solid with purity >95%. Scheme 1. Synthesis of DCLAK11a aReagents and conditions: (a) NaNO2, KI, HCl (aq), 0 °C, 2 h, 79.8 %; (b) CuI, D-Plenylglycinol, K3PO4, L-proline, DMSO, 80 °C, 24 h, 47.4%; (c) Pd(dppf)2Cl2, Na2CO3, dioxane, 90 °C, overnight; (d) trifluoroacetic acid (TFA), CH2Cl2, overnight, two steps` yield: 47.1 %; (e) 5-chloro-2-hydroxyphenylboronic acid, Pd(dppf)2Cl2, K2CO3, dioxane, 130 °C ( MW), 2 h, 43 %.