3 ccr 719-1 state board of pharmacy rules 1

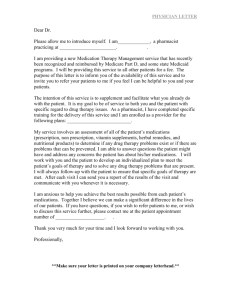

advertisement