Supplementary Information (doc 132K)

Supporting Information (A. Takasu et al.)

EXPERIMENTAL PROCEDURE

Materials: 1,4-Butanediol (1,4-BD), 1,5-pentanediol (1,5-PD), 1,6-hexanediol (1,6-HexD), 1,7-heptanediol (1,7-HepD),

1,8-octanediol (1,8-OD), 1,9-nonanediol (1,9-ND), 3-metyl-1,5-pentanediol (MPD), L-lactide, and scandium trifluoromethanesulfonate [Sc(OTf)

3

] were purchased from Tokyo Kasei (Tokyo japan). 3,3’-Dithiodipropanoic acid

(DTDPA) and tributylphosphine (TBP) were purchased from Wako Pure Chemical (Osaka, Japan). Polycaprolactonediol

(PCLdiol) were purchased from Daicel Chemical Industried, Ltd. (Osaka, Japan). Polyethylenglycol (PEG), hexamethylene diisocyanate, and triethylamine (TEA) were purchased from Nacalai Tesque (Kyoto, Japan). Toluene and

1,4-BD were purified by distillation before use. L-Lactide was purified by recrystallization before use.

Measurements: 1 H-NMR spectra were acquired at 27 ˚C using Bruker Analytik DPX200 and DPX600 spectrometers

(200 MHz, respectively). The chemical shift of tetramethylsilane (TMS) was taken as zero ppm. Number average molecular weights ( M n s) and the polydispersity indexes (PDIs; M w

/ M n s) of the polyesters and the dithiol derivatives were estimated using a size exclusion chromatography (SEC) system included a Tosoh DP8020 pump system, a RI (Tosoh

RI-8020) detector, and Tosoh TSK-GEL SUPERMULTIPOREHZ-M columns calibrated with polystyrene standards.

The eluent was chloroform, the flow rate was 0.35 mL/min, and the temperature was 40 °C. FT IR spectra were recorded in KBr disks using a JASCO FT/IR-430 spectrometer.

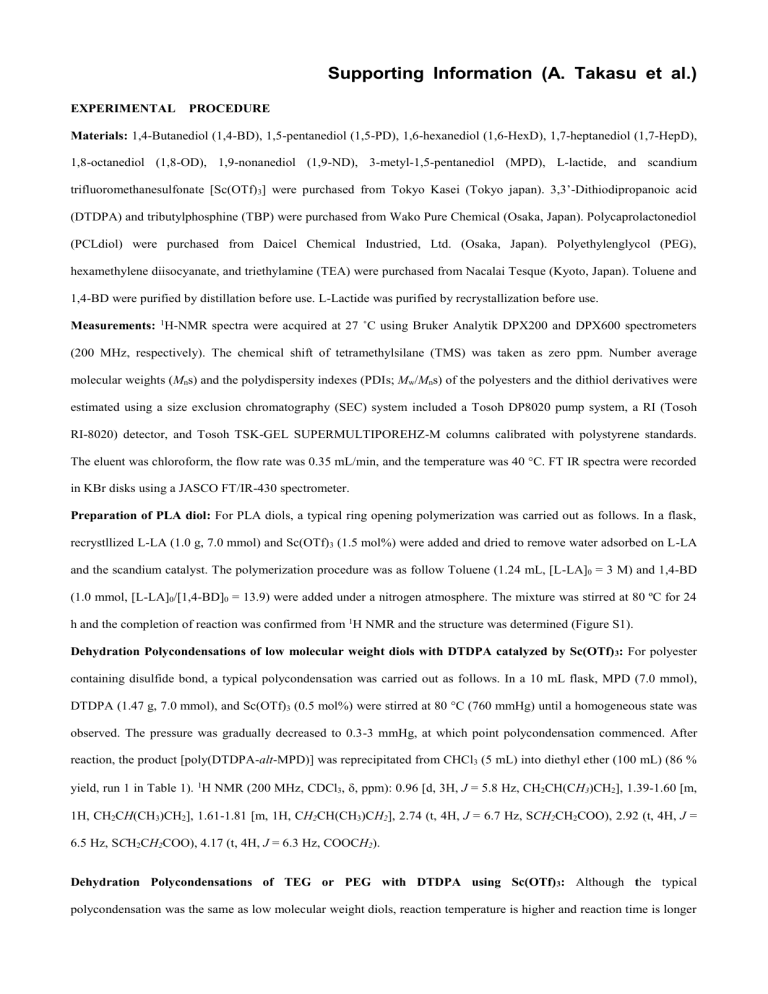

Preparation of PLA diol: For PLA diols, a typical ring opening polymerization was carried out as follows. In a flask, recrystllized L-LA (1.0 g, 7.0 mmol) and Sc(OTf)

3

(1.5 mol%) were added and dried to remove water adsorbed on L-LA and the scandium catalyst. The polymerization procedure was as follow Toluene (1.24 mL, [L-LA]

0

= 3 M) and 1,4-BD

(1.0 mmol, [L-LA]

0

/[1,4-BD]

0

= 13.9) were added under a nitrogen atmosphere. The mixture was stirred at 80 ºC for 24 h and the completion of reaction was confirmed from 1 H NMR and the structure was determined (Figure S1).

Dehydration Polycondensations of low molecular weight diols with DTDPA catalyzed by Sc(OTf)

3

: For polyester containing disulfide bond, a typical polycondensation was carried out as follows. In a 10 mL flask, MPD (7.0 mmol),

DTDPA (1.47 g, 7.0 mmol), and Sc(OTf)

3

(0.5 mol%) were stirred at 80 °C (760 mmHg) until a homogeneous state was observed. The pressure was gradually decreased to 0.3-3 mmHg, at which point polycondensation commenced. After reaction, the product [poly(DTDPAalt -MPD)] was reprecipitated from CHCl

3

(5 mL) into diethyl ether (100 mL) (86 % yield, run 1 in Table 1). 1 H NMR (200 MHz, CDCl

3

, , ppm): 0.96 [d, 3H, J = 5.8 Hz, CH

2

CH(C H

3

)CH

2

], 1.39-1.60 [m,

1H, CH

2

C H (CH

3

)CH

2

], 1.61-1.81 [m, 1H, C H

2

CH(CH

3

)C H

2

], 2.74 (t, 4H, J = 6.7 Hz, S CH

2

CH

2

COO), 2.92 (t, 4H, J =

6.5 Hz, S C H

2

C H

2

COO), 4.17 (t, 4H, J = 6.3 Hz, COOC H

2

).

Dehydration Polycondensations of TEG or PEG with DTDPA using Sc(OTf)

3

: Although t he typical polycondensation was the same as low molecular weight diols, reaction temperature is higher and reaction time is longer

because scandium catalyst tends to coordinate with ethylene glycol units. TEG was reacted at 100 °C for 14 h under reduced pressure (0.3-3 mmHg). PEG was reacted at 100 °C for 77 h and 120 °C for 12.5 h. 1 H NMR for

[poly(DTDPAalt -TEG)] (200 MHz, CDCl

3

, , ppm): 2.77 (t, 4H, J = 6.6Hz, C H

2

COO), 2.93 (t, 4H, SC H

2

CH

2

COO),

3.71 (t, J = 4.8Hz, COOC H

2

).

Dehydration Polycondensations of PCL diols with DTDPA catalyzed by Sc(OTf)

3

: In a 10 mL flask, PCL diol (7.0 mmol), DTDPA (1.47 g, 7.0 mmol), and Sc(OTf)

3

(0.5 mol%) were stirred at 80 °C (760 mmHg) until a homogeneous state was observed. The pressure was gradually decreased to 0.3-3 mmHg, respectively, at which point polycondensation commenced. After reaction, the product [poly(DTDPAalt -PCL)] was reprecipitated from CHCl

3

(5 mL) into diethyl ether (100 mL) (70-90 % yield, run 8-10 in Table 1). 1 H NMR for [poly(DTDPAalt -PCL] of run 8 (200 MHz, CDCl

3

, , ppm): 1.21-1.50 [m, OCO(CH

2

)

2

C H

2

(CH

2

)

2

OCO], 1.50-1.83 (m, OCOCH

2

C H

2

CH

2

C H

2

CH

2

OCO), 2.20-2.45 [m,

OCOC H

2

(CH

2

)

4

OCO], 2.63-2.83 (m, OCOC H

2

CH

2

SS), 2.85-3.01 (m, OCOCH

2

C H

2

SS), 3.63-3.79 (initiater of PCL),

3.96-4.17 [m, OCO(CH

2

)

4

C H

2

OCO], 4.17-4,35 (initiater of PCL)

Dehydration Polycondensations of PLA diols with DTDPA catalyzed Sc(OTf)

3

: The typical polycondensation was the same as low molecular weight diols. However the reaction temperature is higher because reactivity of secondary alcohol is lower than that of primary alcohol. According to a protocol described above, PLA diols was prepared by ring-opening polymerization of L-LA in toluene. After evaporation of toluene, stoichiometric amount of DTDPA (210 mg, 1.0 mmol) was added and stirred at 100 °C (760 mmHg) until a homogeneous state was observed. The pressure was gradually decreased to 0.3-3 mmHg and the mixture was reacted at 100 °C for 6 h and at 120 °C for 22 h. After reprecipitation, expected polyester was obtained (22 and 44 % yield, run 11 and 12 in Table 1, respectively). 1 H NMR

(200 MHz, CDCl

3

, , ppm): 1.50 [s, 4H, C H

2

CH

2

OCH(CH

3

)], 1.58 [d, J = 7.0 Hz, OCOCH(C H

3

)OCO], 2.65-2.88 (m,

4H, SCH

2

C H

2

COO), 2.88-3.04 (m, 4H, SC H

2

CH

2

COO), 4.16 [broad, 4H, CH

2

C H

2

OCH(CH

3

) ],

Cleavage of disulfide linkages using TBP: For dithiols, a typical reduction was carried out as follows. In a 10 mL round bottom flask, poly(DTDPAalt -MPD) was dissolved in mL of chloroform and 8 equiv of TBP was added. The mixture was stirred at room temperature for 24 h. After the reaction was completed, the product was reprecipitated into

100 mL of hexane to remove TBP. The dithiol was dried under reduced pressure until constant weight. For MPD dithiol 1 H NMR (200 MHz, CDCl

3

, , ppm): 0.98 [t, 3H, J = 6.8 Hz, OCH

2

CH

2

CH(C H

3

)CH

2

CH

2

O], 1.26 (t, 2H, J = 7.3

Hz, CH

2

CH

2

S H ), 1.33-1.62 (m, 1H, OCH

2

CH

2

C H (CH

3

)CH

2

CH

2

O), 1.62-1.80 [m, 4H, CH(CH

3

)CH

2

C H

2

O], 2.48-2.68

(m, 4H, OCOC H

2

CH

2

SH), 2.68-2.94 (m, OCOCH

2

C H

2

SH), 4.14 (t, 4H, J = 11.3 Hz, OCOCH

2

C H

2

SH) For PCL dithiol

1 H NMR (200 MHz, CDCl

3

, , ppm) is shown in Figure 2 and MALDI-TOF is shown in Figure S2. For PLA dithiol and

PEG dithiol, 1 H NMR (200 MHz, CDCl

3

, , ppm) spectra are shown in Figure S3 and Figure S4, respectively.

Polyadditnion of dithiols with hexamethylene diisocyanate catalyzed by triethyl amine: For polythiourethane, a typical polyaddithion was carried out as follows. In a 10 mL flask, MP dithiol (74.4 mg, 0.25 mmol) and TEA (1 drop) was dissolved in 0.25 mL of chloroform and hexamethylene diisocyanate (40 μ L, 0.25 mmol) was added in a nitrogen atmosphere. The mixture was stirred at room temperature for 10 minutes and at 60 °C for 2 h. The product was reprecipitated from DMF (5 mL) into diethyl ether (100 mL). The structure was estimated from FT IR (KBr disk, cm -1 ):

3333 (

N-H

), 1732 [

C=O

(ester)], 1568 (

N-H

), 1209 (

S-CH

).

Figure S1.

1

H NMR spectrum of PLA diol in CDCl

3

H O

CH

O

3

H

3

C

O

O

O

O CH

3 m

O a b

O d

H

3

C

O c O

O CH

3

O

CH

3 m

O e OH d

6 c e b

5 4 3

Chemical Shift (ppm)

2 a

1

Figure S2.

MALDI-TOF spectrum of PCL dithiol; Matrix: dithranol

Data: PLACCEL208-10001.C5 30 Sep 2009 10:21 Cal: 9 Jun 2004 17:45

Kratos PC Axima CFRplus V2.4.0: Mode linear, Power: 83, P.Ext. @ 2000 (bin 53)

%Int.

36 mV[sum= 3628 mV] Profiles 1-100: Averaged

100

90

80

70

60

50

40

30

20

10

0

1100 1200 1300 1400

Mass/Charge

1500 1600 1700 1800

Figure S3.

1

H NMR spectrum of PLA dithiol in CDCl

3

H S

O H

3

C

O

O

O

O CH

3 m

O a b

O

H

3

C

O

O

O c O

CH

3 d m

O e f

SH

6 c d b f e

5 4 3

Chemical Shift (ppm)

2 a

1

Figure S4 .

1

H NMR spectrum of PEG dithiol in CDCl

3

H S

O

O

O a

O m b

O

O c d

SH

5 a b d c

4 3

Chemical Shift (ppm)

2

H

2

O

1