BIO577: Media Preparation

BIO577: Media Preparation

During the quarter we will be utilizing bacterial hosts ( Escherichia coli [ E. coli ] or

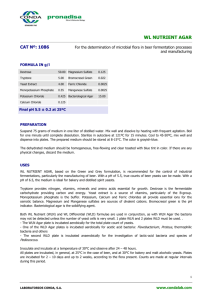

Agrobacterium tumefaciens ) for replicating recombinant DNA plasmids we have engineered. Bacteria need nutrients, a source of energy and certain environmental conditions in order to grow and reproduce. In the environment, microbes have adapted to the habitats most suitable for their needs, in the laboratory, however, these requirements must be met by a culture medium. This is basically an aqueous solution to which all the necessary nutrients have been added. Depending on the type and combination of nutrients, different categories of media can be made.

Categories

Complex media are rich in nutrients, they contain water soluble extracts of plant or animal tissue (e.g., enzymatically digested animal proteins such as peptone and tryptone). Usually a sugar, often glucose is added to serve as the main carbon and energy source. The combination of extracts and sugar creates a medium which is rich in minerals and organic nutrients, but since the exact composition is unknown, the medium is called complex.

Defined media are media composed of pure ingredients in carefully measured concentrations dissolved in double distilled water i.e., the exact chemical composition of the medium is known. Typically, they contain a simple sugar as the carbon and energy source, an inorganic nitrogen source, various mineral salts and if necessary growth factors (purified amino acids, vitamins, purines and pyrimidines).

Selective/differential media are media based on either of the two categories above supplemented with growth-promoting or growth-inhibiting additives. The additives may be species- or organism-selective (e.g., a specific substrate, or an inhibitor such as cyclohexamide which inhibits all eukaryotic growth and is typically used to prevent fungal growth in mixed cultures).

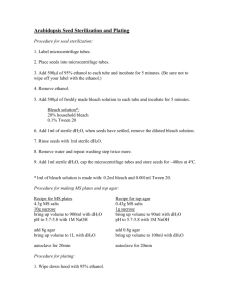

*We will be preparing four different types of media in today’s lab. Each group will make one of the four.

Liquid media

Liquid cultures of E. coli can generally be grown in LB (Luria-Bertani) medium. There are a number of different LB broths, with different compositions, which are commonly used. Different formulations contain different concentrations of NaCl and give rise to varied yields of plasmid DNA. We will be using the recipe at the end of this handout to obtain highest yields of plasmid DNA.

Preparation: To prepare 1 liter of LB medium, add 10 g NaCl, 10 g tryptone and 5 g yeast extract to 950 ml deionized water and stir until dissolved. Adjust the pH to 7.0 with

5 M NaOH. Adjust the volume of the solution to 1 liter with deionized water. Sterilize by autoclaving for 20 minutes.

Solid media

E. coli strains can generally be streaked and stored on LB plates containing 1.5% agar and the appropriate antibiotic(s).

Preparation: Prepare LB medium according to the instructions for liquid media. Just before autoclaving, add 15 grams agar per liter and mix. After autoclaving, swirl the medium gently to distribute the melted agar evenly throughout the solution. Take care that the hot liquid does not boil over when swirled. Pour plates in a laminar-flow hood or, if no hood is available, on a cleaned bench surface next to a Bunsen burner. Use 30–35 ml medium per standard 90-mm petri dish (~30 plates per liter of medium).

Dry plates either directly after solidification by removing the lids and standing the plates in a laminar-flow hood for 1 hour. Alternatively, if you do not have access to a hood, plates can be dried with the covers slightly open in a 37°C incubator for 30 min, or left upside down with lids on at room temperature for 2–3 days.

Store plates inverted at 4°C.

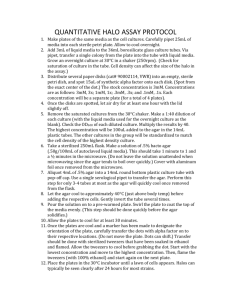

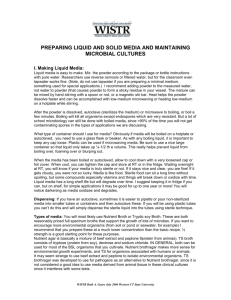

Antibiotics

Bacterial strains carrying plasmids or genes with antibiotic selection markers should always be cultured in liquid or on solid medium containing the selective agent. Lack of antibiotic selection can lead to loss of the plasmid carrying the genetic marker and potentially to selection of faster-growing mutants. Antibiotics and nutrients such as amino acids are inactivated by the high temperatures of an autoclave. They should be sterilized by filtration through a filter unit with a pore size of 0.2 μm, and added to the cooled, autoclaved medium from properly stored stock solutions.

Preparation: Prepare stock solutions of antibiotics separately from batches of liquid or solid media, sterilize by filtration, aliquot, and store in the dark at –20°C. Recommended stock and working concentrations for commonly used antibiotics are shown in the table below. Prepare solid media as outlined above. Cool autoclaved agar medium to below

50°C (when you can hold it comfortably) before adding heat-sensitive antibiotics and nutrients.

Table 1. Concentrations of commonly used antibiotics

Antibiotic

Ampicillin

Stock solutions

Concentration Storage

50 mg/ml in water

–20°C

(sodium salt)

Chloramphenicol 34 mg/ml in ethanol –20°C

Kanamycin 10 mg/ml in water

–20°C

Streptomycin 10 mg/ml in water

–20°C

Tetracycline HCl 5 mg/ml in ethanol –20°C

Working concentration

(dilution)

100 μg/ml (1/500)

170 μg/ml (1/200)

50 μg/ml (1/200)

50 μg/ml (1/200)

50 μg/ml (1/100)

Recipes for media:

Liquid LB

10 g tryptone

5 g yeast extract

10 g NaCl solid LB +Kan a

10 g tryptone

5 g yeast extract

10 g NaCl dH2O to 950 ml

15 g agar solid LB +Chl b

10 g tryptone

5 g yeast extract

10 g NaCl dH2O to 950 ml

15 g agar solid YEP +Chl

20 g peptone

10 g yeast extract dH2O to 950 ml

15 g agar b

All recipes are for one liter total volume.

Liquid LB must be aliquoted out into capped tubes (5 ml for each tube). All solutions must be autoclaved for 20 minutes. Once the solid media has cooled sufficiently, the appropriate antibiotic must be added. a

Kan is the abbreviation for kanamycin. The final concentration of kanamycin should be

50

g/ml. The main stock solution is at a concentration of 50 mg/ml, therefore we will add 1 ml of the main stock to our cooled (but not solidified!) media. bChl is the abbreviation for chloramphenicol. The final concentration of chloramphenicol should be 30

g/ml. The main stock solution is at a concentration of 34 mg/ml, therefore we will add 882

l of the main stock to our cooled media.