POLA_23921_sm_suppinfo

advertisement

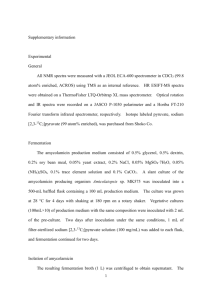

Supporting Information Jacket-like Structure of Donor-Acceptor Chromophores-Based Conducting Polymers for Photovoltaic Cell Applications Yi-Lung Yang,1 Yi-Huan Lee,1 Chun-Jie Chang,1 Ang-Jhih Lu,1 Wei-Chun Hsu,1 Leeyih Wang,1 Man-kit Leung,1 and Chi-An Dai 1,2,* 1 Institute of Polymer Science and Engineering, National Taiwan University, No.1, Sec. 4, Roosevelt Rd. Taipei 10617, Taiwan 2 Department of Chemical Engineering, National Taiwan University, No.1, Sec. 4, Roosevelt Rd. Taipei 10617, Taiwan *Correspondence to: Chi-An Dai (E-mail: polymer@ntu.edu.tw) 1 EXPERIMENTAL SECTION Materials THF and DMF were dried over and distilled from Na and CaH2 under an atmosphere of dry nitrogen. 4,4'-Dibromobenzil (9; 97%, ACROS), benzyltrimethylammonium chloride (98%, ACROS), potassium carbonate (K2CO3; 99%, ACROS), tetrahydrofuran (THF; 99%, Mallinckrodt), tetrakis(triphenylphosphine)palladium(0) (Pd(PPh3)4; 99%, ACROS), diethyl ether (99.9%, Mallinckrodt), MgSO4 (97%, anhydrous, SHOWA), dichloromethane (99.5%, Mallinckrodt), petroleum ether (ACROS), AcOH (99.8%, ACROS), toluene (99.5%, Mallinckrodt), MeOH (99.8%, Mallinckrodt), DMF (99.5%, ACROS), and bromobenzene (99%, ACROS) were used without further purification. All procedures involving air-sensitive reagents were carried out under an atmosphere of high purity argon. Column chromatography was performed on silica gel (230-400 mesh ASTM, Merck silica gel). Conductive ITO coated glass was purchased from Merck Inc. Tetrabutylammonium perchlorate (TBAP) was obtained from TCI and recrystallized twice from ethyl acetate and then was dried in vacuo prior to use. All other chemical reagents were used as received from commercial sources. 1-(4-(9-Butyl-9H-carbazol-3-yl)phenyl)-2-(4-(9-butyl-9H-carbazol-6-yl)phenyl)etha ne-1, 2-dione (10) A mixture of compounds 8 (15.31 g, 57.30 mmol), 9 (8.80 g, 23.90 mmol), benzyltrimethylammonium chloride (0.20 g), potassium carbonate (16.58 g, 120.00 mmol), THF/water (240 mL; 1:1 in volume), and Pd(PPh3)4 catalyst (2.20 g) was carefully degassed and charged with nitrogen. The reaction mixture was heated to reflux for 24 h. After cooled to room temperature, the mixture was extracted with 300 mL of diethyl ether three times. The combined organic phase was separated, washed with brine, dried over anhydrous sodium sulfate, and evaporated to dryness. The residue was purified by column chromatography using a mixture of dichloromethane/petroleum ether (1:1) as the eluent, affording the product of 13.80 g as a yellow solid. Yield: 88%. 1H NMR (400 MHz, CDCl3, ppm): δ 0.96 (t, J = 12 Hz, 6 H), 1.43(m, 4 H), 1.89 (m, 4 H), 4.34 (t, J = 14 Hz, 4 H), 7.27 (t, J = 8 Hz, 2H ), 7.44-7.53 (m, 6 H), 7.77 (d, J = 8 Hz, 2 H), 7.88 (d, J = 10 Hz, 4 H), 8.13 (d, J = 10 Hz, 4 H), 8.16 (d, J = 8 Hz, 2 H), 8.39 (s, 2 H). 13C NMR (100 MHz, CDCl3, ppm): δ 13.86, 20.54, 31.11, 42.97, 109.00, 109.19, 119.25, 119.28, 120.47, 122.78, 123.48, 125.10, 126.11, 127.43, 130.20, 130.61, 130.92, 140.66, 140.94, 148.56, 194.48. 2 3-(4-(5,8-Dibromo-2-(4-(9-butyl-9H-carbazol-3-yl)phenyl)quinoxalin-3-yl)phenyl)-9 -butyl-9H-carbazole (M2) A suspension of compound 3 (53.59 mg, 0.20 mmol) and 10 (65.28 mg, 0.10 mmol) in 7 mL acetic acid was heated to reflux for 6 h, during which time a yellow precipitate formed. After filtration, the resulting solid was purified by recrystallization using a mixture of toluene/MeOH. The residue was purified by column chromatography using a mixture of dichloromethane/petroleum ether (1:1) as the eluent. The product was obtained of 73.01 mg as a yellow solid. Yield: 83 %. 1H NMR (400 MHz, CDCl3, ppm): δ 0.94 (t, J = 15 Hz, 6 H), 1.43 (m, 4 H), 1.88 (m, 4 H), 4.32 (t, J = 14 Hz, 4 H), 7.22 (t, J = 8 Hz, 2 H), 7.40-7.49 (m, 6 H), 7.74-7.77 (m, 6 H), 7.86-7.89 (m, 6 H), 8.13 (d, J = 8 Hz, 2 H), 8.37 (s, 2 H). 13C NMR (100 MHz, CDCl3, ppm): δ 13.91 20.59, 31.16, 42.98, 108.89, 109.03, 118.92, 119.02, 120.48, 122.94, 123.42, 123.68, 125.02, 125.88, 127.10, 130.79, 131.12, 132.87, 135.99, 139.30, 140.24, 140.92, 143.32, 153.91; IR (cm-1, KBr): 1626 (C=N stretching), 1061 (C-N stretching). EI-MS calcd exact mass: m/z 882.2. Found: m/z 882.2. PCPQT (P2) A mixture of 3-(4-(5,8-dibromo-2-(4-(9-butyl-9H-carbazol-3-yl)phenyl) quinoxalin-3-yl)phenyl)-9-butyl-9H-carbazole (M2) (0.60 g, 0.68 mmol) and 2,5-bis(trimethylstannyl)thiophene (11) (0.45 g, 0.68 mmol) in 13 mL DMF was added Pd(PPh3)4 (0.04 g) in a flask under nitrogen atmosphere at room temperature. The reaction mixture was stirred at 85-90 °C for 72 h. After the reaction is completed, bromobenzene was added and the reaction is under reflux for 3hr to complete the capping reaction. The polymer was purified by precipitation in methanol/water (10:1), filtered through filter, and washed on a Soxhlet apparatus with methanol and subsequently with acetone. The polymer was recovered with THF as a green dark powder. Yield: 95 %. 1H NMR (400 MHz, CDCl3, ppm): δ 6.74-8.43 (m, 26n H), 3.84-4.35 (m, 4n H), 0.58-1.91 (m, 14n H); IR (cm-1, KBr): 1626 (C=N stretching), 1061 (C-N stretching), 768 (C-S-C stretching). Mw=11,000 (g/mol), Mn=5,700 (g/mol), PDI=1.96. PCPQT-purified (P2-P) A preparative gel permeation chromatography technique with THF as the eluent was used to remove monomers and oligomers of the as-synthesized PCPQT (P2) after the polymerization. High molecular weight PCPQT (Mw=18,000 (g/mol)) with relatively narrow polydispersity (PDI~1.48) was thus obtained and designated as P2-P. P2-P 3 was further purified by a TAAcOH (SiliaBond R69030B) surface modified silica gel to remove any residual organometallic compounds. The preparative GPC technique was conducted by using a Waters 2695 Alliance HPLC with a preparative column (Polymer Laboratories Ltd, PLgel, 10 μm, 103 Å, Serial No.10M-3-69A-7) using THF as the eluent with a flow rate of 4.8 mL/min at 25 °C. Yield: 35 %. 1H NMR (400 MHz, CDCl3, ppm): δ 6.74-8.43 (m, 26n H), 3.84-4.35 (m, 4n H), 0.58-1.91 (m, 14n H); IR (cm-1, KBr): 1626 (C=N stretching), 1061 (C-N stretching), 768 (C-S-C stretching). Mw=18,000 (g/mol), Mn=12,000 (g/mol), PDI=1.48. 4 FIGURE S1 1H NMR spectra of compounds 10 (a) and M2 (c) in CDCl3; 13C NMR spectra of compounds 10 (b) and M2 (d) in CDCl3. 5 (a) 100 o Td=426 C 90 o Td=351 C 70 (b) 60 50 40 △H Weight ratio (%) 80 o Td=430 C o Tg=108 C 30 20 0 10 50 100 150 Temperature (oC) 200 0 100 200 300 400 500 600 700 o Temperature ( C) FIGURE S2 (a) TGA curves for Comparison of UV-vis absorption spectra of M2 (□), P1 (○), and P2 (△); (b) DSC trace of P2 (△). 6 1.0 Normailized Intensity P1-film 0.8 P2-film 0.6 0.4 0.2 0.0 300 400 500 600 700 Wavelength (nm) 800 FIGURE S3 Comparison of UV-vis absorption spectra of P1 (○) and P2 (▲) in the film state. 7 900 N N N N Br Br M2 8 2 9 * 3 10 M1 11 6 12 7 13 * 8 14 11 15 P2 16 P2-P 17