P199 - World Journal of Engineering

advertisement

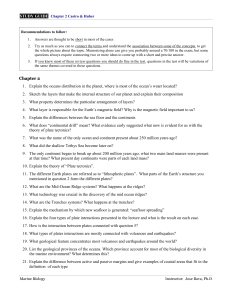

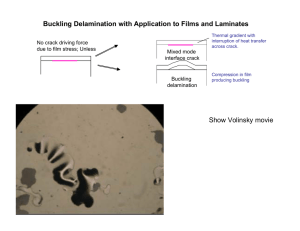

World Journal Of Engineering Numerical study of scale effects on the delamination of laminates under low-velocity impact Yajun Chen, Zhefeng Yu and Hai Wang School of Aeronautics and Astronautics, Shanghai Jiao Tong University, China. the time must also be scaled as ,besides, the maximum strain in the plates is constant with scaling if the impact velocity V is unchanged. Introduction Composite materials are widely used in aerospace structures and automobile, since they have a high specific strength and stiffness, however, they are very susceptible to impact loading, especially low-velocity impact. Low-velocity impact can create internal damage that often cannot be detected by visual inspection. This internal damage can cause reductions in strength by propagating under loading[1]. In order to save time and expense, much testing of composite components has to be carried out on small-scale models by using scaling laws, either on full-scale prototypes. The impact damage in small-scale modes and full-scale prototypes are different, the relationship between them should be understood. Several researcher have studied scale effects in composite[2-5]. This work shows scale effects on impact damage in laminates with different scale factor by FEM method. The objective of the present work was twofold. Firstly, a fully 3-D composite damage model and VUMAT subroutine implemented into ABAQUS are used to predict damage induced by low-velocity impact, especially delamination. Secondly, the delamination size in models with different scale factor is compared. The relationship between delamination size and size of model is studied. Also the contact force scales as 2 , and if the contact area scales geometrically the contact pressure is unchanged. If the impactor also scales geometrically, the impactor mass scales as 3 . Further, the strain should increase linearly with impact velocity. The present results agree with these scaling rules. Finite Element Model Three plates of different geometrically scaled are used to study scale effects on impact damage. The plates made of T300/976 [7] range in size from 30mm by 30mm by 2.3mm thick to 120mm by 120mm by 9.2mm thick. The material properties of T300/976 composites used in the calculations are listed in Table 1. If the scale parameter is termed , the dimensions of the plate are thus scaled by 1, 2, 4 .The layup is (45)4 / (45)4 S . The spherical impactors range in size from 16mm to 64mm.The mass of impactors varies from 0.16kg to 10.24kg, with the mass varying as the cube of the scale factor. The geometries of plates and impactors are given in Table 2. The plate specimens are clamped on four edges. Table 1 Material properties of T300/976 Elastic properties Strength values E11 156GPa XT 1520MPa Scaling Rules E22= E33 9.09GPa XC 1590MPa The scaling rules are based on the dynamic theorem and was particularly developed by Qian and Swanson [6] for plates. They believe that if the geometry of plates is scaled as , G12= G13 6.96GPa YT 45MPa G23 3.24GPa YC 252MPa 12 13 0.228 S 105MPa 0.400 1540kg/m3 23 199 World Journal Of Engineering Table 2 Parameters of plates and impactors Plate Scale size(mm) thickness(mm) Factor Cases 1 30 by 30 2.3 1 2 60 by 60 4.6 3 120 by 120 9.2 Cases Plate Table 3 Delamination area and length Impactor Cases Diameter (mm) Impactor mass (mm) ratio Area Ratio Scale (mm) L (mm2) A Factor 1 18.4 1 92 1 1 2 2 40.3 2.19 743 8.1 2 4 3 85.7 4.66 3941 42.8 4 As shown in Table 3, when scale factor is 2, the delamination length along diagonal direction scales 2.19. Hence, case 1 and case 2 have nearly same relative delamination size if impact velocity varies inversely with square root of plate length, this is confirmed by Y. Qian[5] through experiments. If scale factor is 4, the delamination length along diagonal direction scales 4.66, this is not very accord with the conclusion put forward by Y. Qian. Maybe other factors cause the discrepancy. Moreover, in case 1, delamination occurs on the interface near the back face, however, in case 2 and case 3, delamination takes place on the interface near the front face. The thickness of plate effects the position where delamination arises. The difference should be studied in further work. impact velocity(m/s) 1 30 by 30 2.3 5.89 2 60 by 60 4.6 4.16 3 120 by 120 9.2 2.945 Length A fully 3-D finite element model and Vumat subroutine are used to predict damage in plates under low-velocity impact. Intralaminar damage is predicted through Modified Chang-Chang criteria[8]. The delamination between the ply interfaces is simulated by interface elements. The laminate is modelled with one element per ply. Zero thickness cohesive elements are created between plies with different angles. Results and Conclusion The results of simulation are presented as follows. Figure 1 shows comparison of delamination induced by impact in three different size plates. References [1] Abrate S. Impact on composite structures. Cambridge (UK):Cambridge University Press; 1998. [2] Philippe Viot. Scale effects on the response of composite structures under impact loading. Engineering Fracture Mechanics 2008;75:2725-2736. [3] Y. Qian. An Experimental Study of Scaling Rules for Impact Damage in Fiber Composites. Journal of Composite Materials 1990;24:559-570. (a) case1 30mm by 30mm plate, 5.89m/s impact velocity [4] Y. Qian. "Experimental Measurement of Impact Response in Carbon/Epoxy Plates," Proc. AIAA, ASME, ASCE, AHS, ASC 30th Structures, Structural Dynamics, and Materials Conf., pp. 1023-1031 (1989). [5] Chang, F. K. and L. B. Lessard. 1991. "Damage (b)case2 60mm by 60mm plate,(c)case3 120mm by 120mm plate, 4.16m/s impact velocity 2.945m/s impact velocity Tolerance of Laminated Composites Containing an Open Hole and Subjected to Compressive Loading: Fig 1. comparison of delamination in three different size plates The delamination area and delamination length in diagonal direction are given in Table 3. Part I-Analysis," J. of Composite Materials, 25:2-43. [6] J.P. Hou. Prediction of impact damage in composite plates. Composites Science and Technology 2000; 6060:273-281. 200