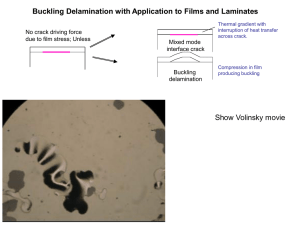

Buckling Delamination with Application to Films and Laminates Show Volinsky movie

advertisement

Buckling Delamination with Application to Films and Laminates No crack driving force due to film stress; Unless Thermal gradient with interruption of heat transfer across crack. Mixed mode interface crack Buckling delamination Compression in film producing buckling Show Volinsky movie Mechanics of thin films and multilayers Application areas electronics, coatings of all kinds. Example: Buckle Delaminations Good Delaminations on Patterned substrates Thermal Barrier Coatings (TBCs) Application to jet and power generating turbines Ceramic (Zirconia) Ceramic (Alumina) Metal bond coat Blades taken from an engine showing areas of spalled-off TBC Buckle Delaminations: Interface cracking driven by buckling Three Morphologies: Straight-sided, Varicose and Telephone Cord Computer simulations Straight-sided Experimental observations 200nm DLC film on silicon Propagation of a buckle delamination along a prepatterned tapered region of low adhesion between film and substrate. In the wider regions the telephone cord morphology is observed. It transitions to the straight-sided morphology in the more narrow region and finally arrests when the energy release rate drops below the level needed to separate the interface. A Model Problem—Mode I Buckling Delamination of Symmetric Bi-layer L P, Δ P, Δ 2h 2b buckled state unbuckled state P PC b b + Δb strain energy=SE = ∫ Pd Δ = This neglects the very slight increase of P as the buckling amplitude increases ΔC Δ Δ 0 1 PC Δ C + PC ( Δ − Δ C ) 2 π 2 Eh 2 PC π 2 h2 PC = 2(hw) L= L , ΔC = 12 b 2 2hwE 12 b 2 Buckling stress of clamped beam length 2b. w is the width perpendicular to the plane. Overall buckling of the entire laminate (with thickness 2h) will not occur if b>L/4. PC 2 L SE = − + PC Δ 4 whE G Energy release rate under prescribed Δ 1 ∂SE G=− 2 w ∂b = Δ π 2 Eh3 6b 3 unbuckled buckled ( Δ − ΔC ) Fixed b two crack tips ΔC Δ Mode I Buckling Delamination of Symmetric Bi-layer: continued The energy release rate G can be re-written in the following non-dimensional form: GL3/ 2 b 12Δ −3 −2 4 3 1 , where = ξ − ξ ξ = ( ) E Δ5 / 2 h π 2L 8 ⎛3⎞ GL3/ 2 The maximum of is 3⎜ ⎟ E Δ 5/ 2 5 ⎝5⎠ 3/ 2 = 1.288 1.5 GL3/ 2 EΔ 5/ 2 1 stable under prescribed Δ occuring for ξ = 5/3 GIC L3/ 2 EΔ 5/ 2 0.5 GIC L3/ 2 If < 1.288, the crack will advance E Δ 5/ 2 if b is such that G = GIC . If b is to the left of the peak the crack is unstable under prescribed Δ and it will jump to the value of b associated with GIC to the right of the peak. If Δ is then increased, the crack grows stabily with b associated with GIC to the right of the peak. unstable under prescribed Δ 0 0 1 unbuckled 2 ξ 3 4 5 Abbreviated Analysis of the Straight-Sided Buckle Delamination A 1D analysis based on vonKarman plate theory (See next 2 pages) Propagation direction G front Film pre-stress Gsides h Average stress in buckled film: Buckle deflection: 1 w( y ) = δ (1 + cos(π y / b) ) 2 Buckle amplitude: ⎞ δ 4⎛ σ = − 1 ⎜ ⎟ h 3 ⎝ σC ⎠ π2 ⎛h⎞ σC = E1 ⎜ ⎟ 12 ⎝ b ⎠ 2 h (σ − σ C )(σ + 3σ C ) E1 1 1 b 2 π2 2 (σ − σ C ) = ∫−b w′ dy = δ E1 2 8b At edge of buckle: E1h3 π 2δ ΔN = (σ − σ C )h , M = 12 2b 2 Energy release rate and mode mix along sides from basic solution: Gsides = In-plane compatibility condition 4 + 3(δ / h) tan ω tanψ = −4 tan ω + 3(δ / h) Energy release rate along propagating front G front = 1 b h 2 = σ − σ G dy ( ) sides C 2b ∫−b E1 Discussed in class Energy-release rate can also be obtained from direct energy change calculation Mode mix depends on the amplitude of The buckle Plots are given 3 slides ahead Digression—Von Karmen nonlinear plate theory applied to clamped wide plates Plate is infinite in z direction. Deformation is plane strain with y E = E /(1 −ν ) p ( x) 2 w( x) • Strain-displacement relations: • mid-surface strain: ε = u ′ + 12 w′2 ; mid-surface curvature: κ = w′′ u ( x) Stress-strain relations: (for plate of thickness h) N ≡∫ h/2 −h / 2 σ dy = Ehε , M ≡ − ∫ h/2 −h / 2 σ ydy = Dκ , D = Eh3 /12 δ h Equilibrium equations: (obtained from principle of virtual work) Moment equil.: M ′′ − Nw′′ = p; Horizontal equil.: N ′ = 0 By equilibrium, N is independent of x Finite deflection solution for buckling of clamped-clamped beam (wide plate) 2b Notation: average compressive stress in unbuckled beam: σ = − N / h average compressive stress in buckled beam: σ C = − N C / h deflection at center of buckle: δ = w(0) beam length = 2b (−b ≤ x ≤ b) With the left end fixed, impose a displacement u = −Δ on the right end and then hold that end fixed. The compressive stress in the unbuckled beam is σ = E Δ /(2b). Moment equil. ⇒ Dw′′′′ + σ C h w′′ = 0; ( p = 0); clamped BC's ⇒ w = w′ = 0, x = ±b This is an eigenvalue problem with σC as the eigenvalue. Note that this stress will be independent of the amplitude of w. Continued on next slide x Von Karmen nonlinear plate theory applied to clamped wide plates--continued ⎛ σCh ⎞ ⎛ σCh ⎞ x ⎟⎟ + c4 cos ⎜⎜ x ⎟⎟ General solution ⇒ w = c1 + c2 x + c3 sin ⎜⎜ D D ⎝ ⎠ ⎝ ⎠ ⎛ σCh ⎞ For the lowest eigenvalue, the BCs ⇒ c2 = c3 = 0, sin ⎜⎜ ⎝ D b ⎟⎟ = 0, c1 = c4 . ⎠ π2 δ⎛ ⎛h⎞ ⎛ π x ⎞⎞ Thus, the stress in the buckled beam and the deflection shape are: σ C = E ⎜ ⎟ & w( x) = ⎜1 + cos ⎜ ⎟⎟ 12 ⎝ b ⎠ 2⎝ ⎝ b ⎠⎠ 2 Relation between stress in buckled beam, stress in unbuckled beam and deflection With u and w measured from the unstressed state and u measured from the unbuckled stressed state, ( N C = Ehε ⇒ − σ C h = −σ h + Eh u′ + 12 w′2 ) Now integrate the above equation from -b to b using u ( −b) = u (b) = 0 : ⇒ σ −σC = π2 ⎛δ ⎞ E b 2 ′ w dx E⎜ ⎟ = 4b ∫− b 16 ⎝ b ⎠ 2 or δ =h ⎞ 4⎛ σ − 1⎟ ⎜ 3 ⎝ σC ⎠ δ h Finally, we will need the moment at x = b: E ⎛π ⎞ M (b) = Dw′′(b) ⇒ M (b) = ⎜ ⎟ δ 24 ⎝ b ⎠ This completes the finite deflection for the clamped-clamped wide plate. 2 1 σ σC BASIC ELASTICITY SOLUTION FOR INFINITE ELASTIC BILAYER WITH SEMI-INFINITE CRACK (Covered in earlier lectures and included here again for completeness) Equilibrated loads. General solution for energy release rate and stress intensity factors available in Suo and Hutchinson (1990) Infinitely thick substrate-Primary case of interest for thin films and coatings on thick substrates moment/length M Dundurs’ mismatch parameters for plane strain: E − E2 E αD = 1 , E= E1 + E2 (1 −ν 2 ) βD = force/length delamination crack interface E2 ,ν 2 E 1 μ1 (1 − 2ν 2 ) − μ2 (1 − 2ν 1 ) , μ= 2 μ1 (1 −ν 2 ) + μ2 (1 −ν 1 ) 2(1 +ν ) For homogeneous case: αD E1 ,ν 1 P αD = βD = 0 If both materials incompressible: βD = 0 is the more important of the two parameters for most bilayer crack problems Take β D = 0 if you can. It makes life easier! h Basic solution continued: Energy release rate M 1 ⎛ P2 M2 ⎞ + 12 3 ⎟ G= ⎜ d ⎠ 2 E1 ⎝ d E1 ,ν 1 P delamination crack E = E /(1 −ν ) 2 1 ⎡ −1/ 2 −3/ 2 + Pd ω Md cos 2 3 sin ω ⎤⎦ ⎣ 2 1 ⎡ −1/ 2 K II = Pd sin ω − 2 3Md −3/ 2 cos ω ⎤⎦ ⎣ 2 where ω (α D ) is shown as a plot and is tabulated in Suo & Hutch. Note: For any interface crack between two isotropic materials, 1 − βD2 ⎛ 1 1 ⎞ 2 2 + G= ⎜ ⎟ ( K I + K II ) 2 ⎝ E1 E2 ⎠ interface E2 ,ν 2 Stress intensity factors: ( β D = 0) (see Hutchinson & Suo (1992) if second Dundurs’ parameter cannot be taken to be zero) KI = h 70 65 βD = 0 60 no mismatch 55 o 52.1 50 • 45 -1 -0.5 0 0.5 α 1 D K I , K II Interface toughness—the role of mode mix Experimental finding: The energy release rate required to propagate a crack along an interface generally depends on the mode mix, often with −2 larger toughness the larger the mode II component. Γ C (ψ ) ( Jm ) Interface Toughness: Γ C (ψ ) Propagation condition: G = Γ C (ψ ) A phenomenological interface toughness law λ ≅ 0.1 ΓC (ψ ) = Γ IC (1 + tan 2 ((1 − λ )ψ ) ) ΓC (ψ ) Γ IIC / Γ IC ψ λ = .1, .2, .5, 1 Liechti & Chai (1992) data for an epoxy/glass interface. ψ in degrees λ λ = 1 ⇒ no mode dependence λ <<1⇒ significant mode dependence Energy release rate and mode mix on sides of Straight-sided buckle delamination π2 ⎛h⎞ σC = E1 ⎜ ⎟ 12 ⎝ b ⎠ 2 Stress at onset of buckling 1.5 0 mode mix along the delamination sides -20 sides bC π E1 = h 12 σ 2 1 σ 2h G0 = 2 E1 Half-width at onset of buckling Energy/area available for release in planes strain 1 -40 α =-1/2, 0, 1/2 D 0.5 -60 curved front Pure mode II -80 0 2 4 6 8 σ/σ =(b/b ) C 2 G = Γ IC f (ψ ), 6 8 σ/σ =(b/b ) C f (ψ ) = 1 + tan 2 ((1 − λ )ψ ) G0 f (ψ ) = σC ⎞ Γ IC ⎛ σ C ⎞ ⎛ ⎜1 − ⎟ ⎜1 + 3 σ ⎠⎝ σ ⎟⎠ ⎝ 4 10 2 C 10 8 See earlier slide for interface toughness function ⇒ 2 C Half-width of straight-sided delamination Impose: 10 6 Stable configurations (half-widths, b) of 1D delaminations Mode II 4 αD = 0 λ =0.2,0.4, 0.6, 0.8, 1 2 d ⎛ G ⎞ ⎜ ⎟ < 0. db ⎝ f (ψ ) ⎠ i.e. if tip "accidentally" advances, it is no longer critical. Stability of crack front requires: 0 2 4 6 8 σ/σC=(b/b C) Caution! This plot is difficult to interpret because each axis depends on σ 2 10 Illustration of Spread of Delamination if no mixed mode dependence (λ = 1 & G = Γ IC ) Scenario: Given Γ IC & initial delamination flaw with length 2b0 . Monotonically increase the pre-stress (the stress in the unbuckled film), σ . This is the pre-stress, σ , at which crack will advance. G Note that once the interface crack advances, G > Γ IC and it will spread dynamically without limit. For mode-independent interface toughness the condition to ensure no "wholesale" delamination is G0 < Γ IC , or σ 2h < Γ IC . 2E Stresses well above this level can be tolerated if the Γ IC interface toughness has a significant mixed mode dependence. σ = σ C0 σ <σ Since the delamination becomes mode II as it 0 C spreads, the above simple criterion against complete delamination can generalized when there is mode-dependence of the toughness by σ = buckling stress 0 C associated with b0 b0 b the requirement, G0 < Γ IIC . But such a criterion would not exclude localized delaminations such as telephone cord delaminations. Inverse determination of interface toughness, stress (or modulus) by measuring buckling deflection and delamination width Straight-sided delamination without ridge crack on flat substrate S ∼ stretching stiffness D ∼ bending stiffness front (SS) The basic results can be written as: side 1 ⎛π δ ⎞ GSS = S ⎜ ⎟ 2 ⎝4 b⎠ 4 1 ⎛ π δ⎞ ⎛ π ⎞ ⎛ π δ⎞ = S + 2D ⎝ b⎠ ⎝ 4 b⎠ 2 ⎝ 4 b⎠ 4 Gside ⎛π⎞ ⎛π δ ⎞ N 0 = D⎝ ⎠ + S ⎝ b 4 b⎠ 2 2 2 2 Applies to any multilayer film with arbitrary stress distribution If bending and stretching stiffness of the film are known, then the energy release rates and the resultant pre-stress can be determined by measurement of the deflection and the delamination width. If resultant pre-stress is known, then the equations can be used to determine film modulus and release rates in terms of deflection and delamination width– see Faulhaber, et al (2006) for an example. Energy Released as a Function of Morphology Three morphologies: DLC on silicon—tapered low adhesion interface: propagates from right to left Film under equi-biaxial stress Energy/area: σ 2h U0 = E (1 −ν ) Energy/area in buckled film averaged over one full wavelength: For σ / σ C < 6 : U Euler (straight-sides) mode is only possible mode σ / σ C = (b / bC ) 2 For σ / σ C > 7.5 : Telephone cord morphology has lowest energy and releases the most energy/area. Moon et al 2004 Metal or Ceramic Films on Compliant Substrates (Polymer or Elastomer) Cotterell & Chen, 2000; Yu & Hutch, 2002; Parry, et al.,2005 Analytical Fact: Edges of buckle delamination is effectively clamped if substrate modulus is larger than 1/3 of film modulus (i.e. clamped plate model is valid) Highly compliant substrate has three effects: 1) Stabilizes straight-sided buckle delamination and tends to eliminate telephone cord morphology. 2) Significant film rotation occurs at edges of delamination and larger buckling deflections. 3) Relaxation of stress along bonded edges of delamination (shear lag effect) amplifies energy released. Shear lag relaxation of stress in bonded film Compliant substrate: simulations and exps. Ni films on polycarbonate substrates (Parry, et al.) clamped model greater rotation along edges