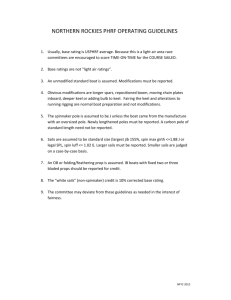

Forward Established in 1946, UK Sailmakers is one of the oldest

advertisement