EPUSIL EP 333 PW - I

advertisement

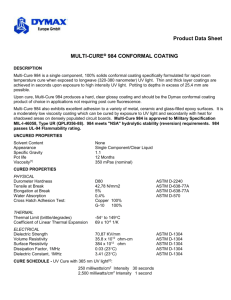

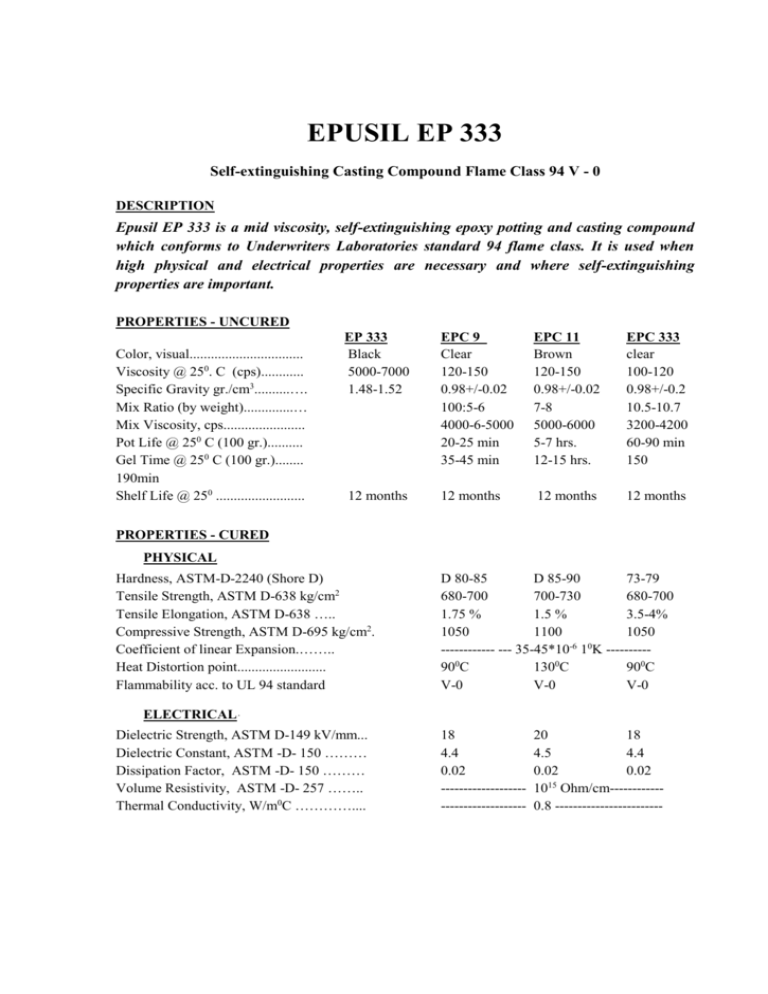

EPUSIL EP 333 Self-extinguishing Casting Compound Flame Class 94 V - 0 DESCRIPTION Epusil EP 333 is a mid viscosity, self-extinguishing epoxy potting and casting compound which conforms to Underwriters Laboratories standard 94 flame class. It is used when high physical and electrical properties are necessary and where self-extinguishing properties are important. PROPERTIES - UNCURED Color, visual................................ Viscosity @ 250. C (cps)............ Specific Gravity gr./cm3..........…. Mix Ratio (by weight)..............… Mix Viscosity, cps....................... Pot Life @ 250 C (100 gr.).......... Gel Time @ 250 C (100 gr.)........ 190min Shelf Life @ 250 ......................... EP 333 Black 5000-7000 1.48-1.52 EPC 9 Clear 120-150 0.98+/-0.02 100:5-6 4000-6-5000 20-25 min 35-45 min EPC 11 Brown 120-150 0.98+/-0.02 7-8 5000-6000 5-7 hrs. 12-15 hrs. EPC 333 clear 100-120 0.98+/-0.2 10.5-10.7 3200-4200 60-90 min 150 12 months 12 months 12 months 12 months PROPERTIES - CURED PHYSICAL Hardness, ASTM-D-2240 (Shore D) Tensile Strength, ASTM D-638 kg/cm2 Tensile Elongation, ASTM D-638 ….. Compressive Strength, ASTM D-695 kg/cm2. Coefficient of linear Expansion.…….. Heat Distortion point......................... Flammability acc. to UL 94 standard D 80-85 D 85-90 73-79 680-700 700-730 680-700 1.75 % 1.5 % 3.5-4% 1050 1100 1050 -6 0 ------------ --- 35-45*10 1 K ---------900C 1300C 900C V-0 V-0 V-0 ELECTRICALּ Dielectric Strength, ASTM D-149 kV/mm... Dielectric Constant, ASTM -D- 150 ……… Dissipation Factor, ASTM -D- 150 ……… Volume Resistivity, ASTM -D- 257 …….. Thermal Conductivity, W/m0C ………….... 18 4.4 0.02 ------------------------------------- 20 18 4.5 4.4 0.02 0.02 1015 Ohm/cm-----------0.8 ------------------------ Epusil EP 333 Page 2 MIXING INSTRUCTION 1. Mix the contents of EP 333 in its original container. 2. Weigh out required amount of Epusil EP 333 3. Weigh into EP 333 appropriate curing agent in the following mix ratio: EPC 9 – 5 to 6 parts per 100 parts of EP 333 EPC 11 – 7 to 8 parts per 100 parts of EP 333 EPC 333 10.5- 10.7 parts per 100 parts of EP 333 4. Mix thoroughly, being careful to scrap sides and bottom of container to ensure proper blending. 5. Evacuate for 5 to 10 minuet if required. 6. Pour into cavity or mold. CURE SCHDULE EPC 9 - Cure 2 to 3 hours at room temperature or accelerated cure times is possible with higher temperature but only after first degree of curing for small mass casting. EPC 11 - Cure for 4 to 5 hours, then at 750C for 2 to 3 hours and post cure of 2 to 3 hours at 1300C. For large mass cure at room temperature until it gels and than post cure at 800C for 2 hrs, 100, 1300 C up to 1500Cfor 2 to 3 hours in accordance April 2003