Product Data Sheet - Lindberg & Lund AS

advertisement

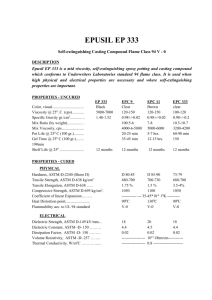

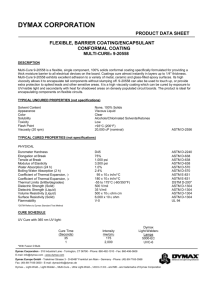

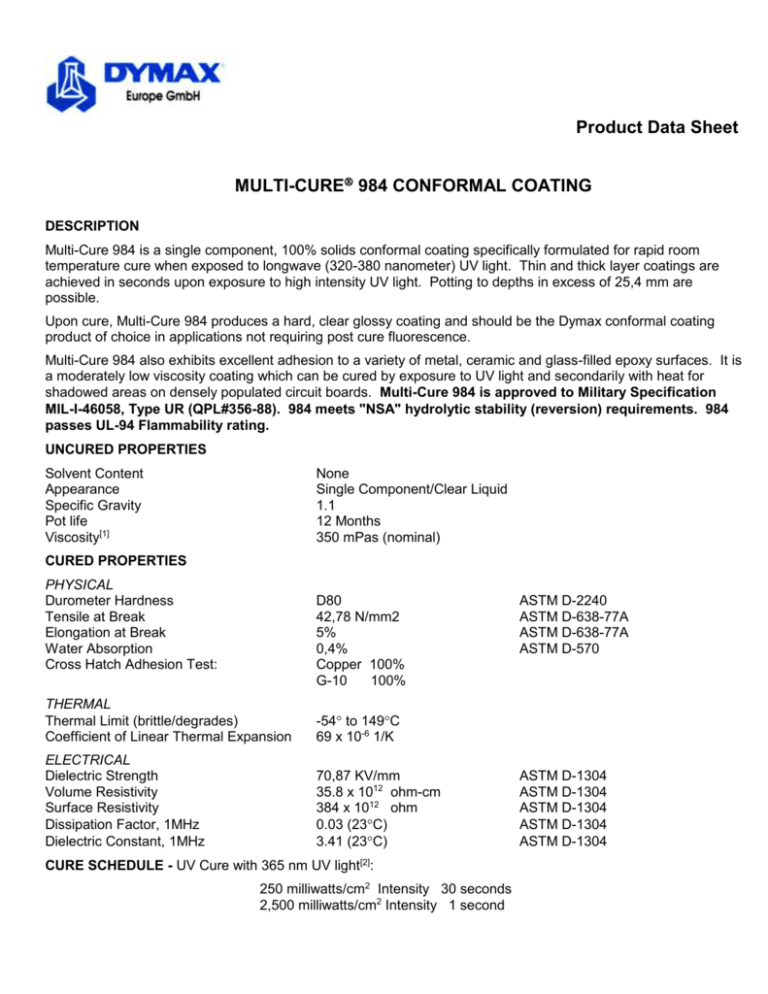

Product Data Sheet MULTI-CURE 984 CONFORMAL COATING DESCRIPTION Multi-Cure 984 is a single component, 100% solids conformal coating specifically formulated for rapid room temperature cure when exposed to longwave (320-380 nanometer) UV light. Thin and thick layer coatings are achieved in seconds upon exposure to high intensity UV light. Potting to depths in excess of 25,4 mm are possible. Upon cure, Multi-Cure 984 produces a hard, clear glossy coating and should be the Dymax conformal coating product of choice in applications not requiring post cure fluorescence. Multi-Cure 984 also exhibits excellent adhesion to a variety of metal, ceramic and glass-filled epoxy surfaces. It is a moderately low viscosity coating which can be cured by exposure to UV light and secondarily with heat for shadowed areas on densely populated circuit boards. Multi-Cure 984 is approved to Military Specification MIL-I-46058, Type UR (QPL#356-88). 984 meets "NSA" hydrolytic stability (reversion) requirements. 984 passes UL-94 Flammability rating. UNCURED PROPERTIES Solvent Content Appearance Specific Gravity Pot life Viscosity[1] None Single Component/Clear Liquid 1.1 12 Months 350 mPas (nominal) CURED PROPERTIES PHYSICAL Durometer Hardness Tensile at Break Elongation at Break Water Absorption Cross Hatch Adhesion Test: D80 42,78 N/mm2 5% 0,4% Copper 100% G-10 100% THERMAL Thermal Limit (brittle/degrades) Coefficient of Linear Thermal Expansion -54 to 149C 69 x 10-6 1/K ELECTRICAL Dielectric Strength Volume Resistivity Surface Resistivity Dissipation Factor, 1MHz Dielectric Constant, 1MHz 70,87 KV/mm 35.8 x 1012 ohm-cm 384 x 1012 ohm 0.03 (23C) 3.41 (23C) CURE SCHEDULE - UV Cure with 365 nm UV light[2]: 250 milliwatts/cm2 Intensity 30 seconds 2,500 milliwatts/cm2 Intensity 1 second ASTM D-2240 ASTM D-638-77A ASTM D-638-77A ASTM D-570 ASTM D-1304 ASTM D-1304 ASTM D-1304 ASTM D-1304 ASTM D-1304 Product Data Sheet Heat Cure Following UV Exposure Heat can be used as a secondary cure mechanism where all adhesive cannot be cured with UV light. UV cure must be done prior to heat cure. Application may employ dip, spray or curtain coat. The following cure schedule may be used: 110C 120C 150C 1 hour 30 minutes 15 minutes FACTORS AFFECTING CURING Dark surfaces lengthen cure time. Thicker films require longer cure times. Full range (UV-A, B & C) lamps provide faster cures than filtered sources. All UV sources degrade with use. Check output periodically with a radiometer. Light intensity decreases as distance from UV source increases. HANDLING AND DISPENSING ADHESIVE Typically Dymax 984 is dipped or sprayed. For questions relating to dispensing, curing systems, the products or the use of products, contact Dymax Technical Service. Repeated or continuous skin contact may cause sensitization and should be avoided. Do not wear jewelry. The use of barrier hand cream is recommended. Do not wear absorbent gloves. Adhesive may be removed with hand soap and water. Avoid eye contact. See CAUTION below. Wipe excess adhesive with paper towels; remove residue with chlorinated solvents, freon, methanol, ethanol, or isopropanol. STORAGE AND SHELF LIFE Do not expose to UV light source or sunlight. Product has a one year minimum shelf life when stored below 32C and out of sunlight and in original, unopened container. Dymax product 984 does not support fungal or bacterial growth. CAUTION For industrial use only. Avoid breathing vapors. Avoid contact with eyes and clothing. In case of contact, immediately flush with water for at least 15 minutes; for eyes, get medical attention. Wash clothing before reuse. Keep out of reach of children. Do not take internally. If swallowed, vomiting should be induced at once and a physician called. For specific information, refer to the product’s Material Safety Data Sheet before use. NOTES [1] [2] Measured at 20 rpm and 25C using a Brookfield Model RVF Viscometer. Euv = mW.s = mJ cm2 cm2 For example, if the intensity of a light source is 2500 mW/cm2 and a part is exposed for 1 second, then the total UV energy would be 2500 mJ or 2.5 J/cm2. cm2 Distributed by: DYMAX Europe GmbH Trakehner Str. 3 60487 Frankfurt/Main Phone: +49-(0)69-7165-3568 Fax: +49-(0)69-7165-3830 e-mail: dymaxinfo@dymax.de Internet: www.dymax.com The data contained in this bulletin which represents typical results, is furnished for information only, and is believed to b e reliable. We cannot assume responsibility for results obtained by others over whose methods we have no control. It is the user's responsibility to determine suitability for the user's purpose of any product o r method mentioned herein and to adopt such precautions as may be advisable for the protection of property and persons against any hazards that may be involved in the handling and use thereof. Nothing in this bulletin is to be inte rpreted as a representation of freedom from domination of patents owned by others or a license under a Dymax Corporation patent. W e recommend that each prospective user test the proposed application before repetitive use, using the data as a guide. For specific information, refer to Material Safety Data Sheet before use. 984/12/98