View - Balco, Inc.

Balco, Inc. BCSF-SL Series Pre-compressed Floor Seal with Traffic Grade Silicone Facing

Choose the applicable items from each section below

1.06 SYSTEM DESCRIPTION

A.

Pre-compressed seals shall permit unrestrained movement of the joint without disengagement of or damage to the seal. Pre-compressed seals must conform to the requirements of ASTM

E1399.

1. Specify x-axis joint movement. (Joint expansion and contraction; Specify for each building

level: floor)

2. Specify y-axis joint movement. (Joint shear movement; Specify for each building level:

floor)

B.

Allowable load on floor joint cover plate shall be psf uniform load and concentrated load (uniform load: 50, 100, 2000 (concentrated load: 300 Pounds, 2,000 pounds)

C.

Fire rated joint cover systems shall have been tested in accordance with ASTM E1966 or UL 2079 and shall be rated for [1 hour] [2 hours]

2.02 MATERIALS

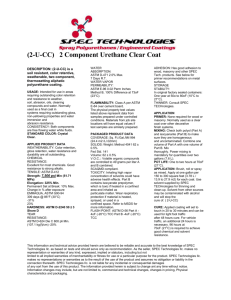

A. Pre-compressed Floor Seal shall be Balco, Inc. BCSF-SL Series

1. Pre-compressed Seal a. b.

Shall be polyurethane, microcell foam.

Shall have the following properties

Physical Properties

Material

Density

Thermal Conductivity

Temp. Stability Range

Staining/Bleeding,.

Elongation, ASTM D3574

Resistance to Compression Set, ASTM D3574

Mildew Resistance

Staining

Flash Point

2. Silicone facing shall be traffic grade, and shall have the following physical characteristics:

Tensile Strength, ASTM D3574

Thermal Resistance, ASTM C518

Requirements

Polyurethane Foam

5.5-6.5 lbs/cu. Ft.

0.05W/m °C

-40°F to 185°F (-40°C to 85°C)

None at 212 °F at 20%

21 psi min.

125% ±20%

3.3, hr-°F-ft2/Btu

Max 2.5%

Excellent

None -40 °F to 185 °F

590 °F

Color

Durometer, Hardness, Shore A

Elongation, Min.

Gray

15-25

1200%

3.

Specific Gravity

Cure Time at 25 °C (77 °F)

1.450-1.515

7-14 Days

Adhesive: The adhesive shall be a two-component, epoxy-based adhesive; which is mixed at the jobsite. The adhesive shall have the following properties:

Adhesive type

Tensile Strength

Pot Life

Flash Point

Non-volatile content

Initial Curing Time

Complete Cure

2-component thixotropic paste

4000 psi

60 minutes at 68°F (20°C)

>200°F (93°C)

100% reactive – Part A

99.9% reactive – Part B

24 hours

7 days at room temperature

68°F (20°C)

4. Traffic Plate: Joint systems for joint having a nominal static width of 2” or wider shall include

5. and [aluminum] [stainless steel] traffic plate. a. b.

Aluminum:

1). Aluminum plate shall be ASTM B209, alloy 6061-T6

2). Aluminum sheet shall be ASTM B209, alloy 5052-H32

Stainless Steel shall be ASTM A666, type 304

Fire Barrier: choose the appropriate fire barrier(s) from the list below

Metaflex 5000 MetaBlock tested in accordance with UL 2079 and/or ASTM E1966, *

*including hose stream test, where applicable, at the full rated period

6. Fasteners, accessories, sealant and other materials required for complete installation in accordance with the manufacturer’s written installation instructions.