Solvent effect on electrospinning of hydrophilic copolymers based

advertisement

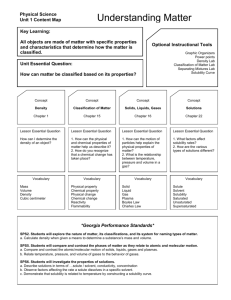

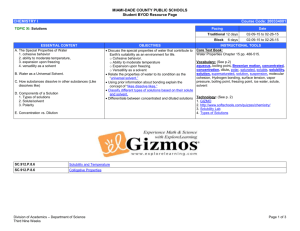

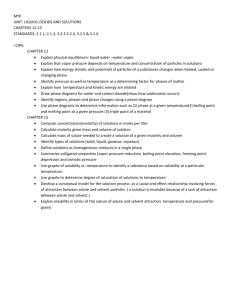

Solvent effect on electrospinning of hydrophilic copolymers based on 2hydroxyethyl methacrylate with 2-ethoxyethyl methacrylate L. Martinováa, D. Lubasováa, M. Přádnýb a Technical University of Liberec, Department of Nonwovens, Studentská 2, Liberec, 461 17, Czech Republic b Institute of Macromolecular Chemistry, Academy of Sciences of the Czech Republic; Prague, Czech Republic lenka.martinova@tul.cz The effect of different types of solvents, solvent mixtures and properties of solvents on electro-spinability of prepared solutions of hydrophilic copolymers based on 2-hydroxyethyl methacrylate (HEMA) and 2-ethoxyethyl methacrylate (EOEMA) were investigated. Morphological appearances of electrospun copolymer nanofibers were subsequently analyzed. Though basic solvent for these copolymers is ethanol or its mixture with water, different cosolvents strongly influence not only electrospinning process by Nanospider technology (Jirsak et al., 2005) but also morphology of processed nanofibers. Biocompatible polymers based on HEMA or its copolymer with EOEMA are attractive candidate materials for tissue engineering. The latter co-monomer reduces the hydrophilicity of poly(HEMA), without significant deterioration of biocompatibility and mechanical properties of the resulting material. Nanofiber sheets from copolymers HEMA/EOEMA with different co-monomer ratio and from pure poly(EOEMA) were successfully tested as scaffolds regarding of this geometric characteristic (pore size, porosity) and physiochemical properties. In the electrospinning process of polymer solution, solvent is one of the main contributors for solution properties, e.g. conductivity or viscosity. Solvent can influence diameter of nanofibers, porosity, efficiency of process and above all development of electrospinning process. Thus copolymer HEMA/EOEMA dissolution behavior in different solvents or their mixture plays an important role. Solubility parameters can be determined by direct measurement, correlation with other physical parameters, or indirect calculations. Solubility parameters are of technical importance in the fields of spinning fibers and casting films (Small, 1953). First of all we tried to use the one-component Hildebrand solubility parameter for prediction of solvent optimal mixture for copolymer HEMA/EOEMA. This parameter is useful for regular solutions, e.g. solutions without molecular polarity or specific interactions. The solubility parameter has been defined as the square root of the cohesion energy density (CED) and describes the attractive strengths between molecules of the material. But our results were not sufficiently predicative. We decided to employ the Hansen´s threecomponent solubility parameters. Hansen (1967, 1983) proposed a practical extension of Hildebrand parameter method for polar, non-polar and H-bonding systems, primarily for use in polymer-liquid interactions. The Hansen parameter was calculated firstly for pure poly(HEMA) and poly(EOEMA) polymer. Many solvents and their mixtures in different proportions (ethanol, acetone, chloroform, 1,2-dichlormethane, dichlorethane) were used for preparation of nanofibers. The aim was to find a solvent, in which Hansen dispersion, polar and H-bonding parameters are similar as in HEMA/EOEMA (30/70) co-polymer and pure poly(EOEMA). The solubility parameter for each component was estimated using the group contribution method described by van Krevelen (van Krevelen,1972). As optimal composition of solvent mixture was confirmed a mixture of ethanol/2-isopropanol (50/50 wt). Effect of co-solvent induced different average fiber diameter or porosity of nanofibers. Nanofiber sheets from HEMA/EOEMA were successfully electrospun using continual electrospinning process Nanospider and sheets were tested for proliferation of hepatocytes and mezenchymal cells. (A) (B) Fig.1: SEM micrographs of nanofiber sheets prepared (A) from copolymer HEMA/EOEMA (30/70) dissolved in ethanol with concentration 10 wt%, Mag.1000x, (B) copolymer HEMA/EOEMA (30/70) dissolved in the mixture dichlormethane /methanol (96/4 vol.) with concentration 10 wt %. Mag.10 000x. References [1] Small, P.A. (1953), J Appl Chem 3, 1953, 71. [2] Behravesh, E., Yasko, A.W., Engel, P.S., Mikos, A.G. (1999), Clin Orthop; 367S: S18S125. [3] Athanasiou, K.A, Niederauer, G.G., Agrawal, C.C.(1996), Biomaterials 1996;17: 93-102. [4] Jirsák ,O., Sanetrník, F., Lukáš., Kotek, V., Martinová, L, Chaloupek, J. (2005), CZ Patent, 294274 (B6), WO 2005024101. [5] .Hansen, C.M, (1967), J Paint Technol 39, 1967, 104-117. [6] Hansen, C.M., Wallstrom, E.(1983), J Adhes,15, 275-286. [7] Van Krevelen, D.W., Hoftyzer, P.J. (1972), Properties of Polymers. Correlation with Chemical Structure; 1972, Elsevier: NY.