OLIVE OIL MILL EFFLUENT (OMW): A WASTE OR A RAW MATERIAL

advertisement

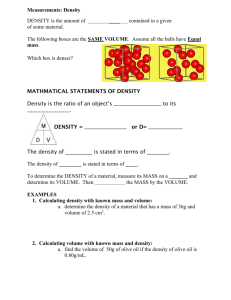

Phenolic compounds in olive oil milling effluents: An environmental problem or a raw material? O. Tzoraki1, A.Voutetaki1, P. Ignatiadis1, N. Passadakis2 and V. Gekas1 1 Environmental Engineering Department, 2 Mineral Resourses Engineering Department, Technical University of Crete, Campus 731 00, CHANIA, Tel. 0821-37486, Fax 0821-37474, e-mail: vgekas@enveng.tuc.gr ABSTRACT Various phenolic compounds are contained in olive oil and are also found in the effluents of two-phase or three-phase olive-oil milling treatments. In olive oil they are known for their anti-oxidative properties and quality retention. During olive oil processing they rather possess a disposal /treatment problem when under uncontrolled conditions pass into the surface or subsurface waters, converted by oxidation and/or polymerization into annoying (phytotoxic and antibacterial) pollutants. Our Laboratory of Transport Phenomena participates in a project for the enhanced utilization of nutritious olive poly-phenols. Rather facing poly-phenols as a pollution problem, the idea is to recover them and use them as raw material for the development of added value products in pharmacy, cosmetics and also in the food industry as food additives. Increasing attention has been paid in discovering a recovery and purification method of polyphenols from the wastewater . They can be reused as a raw material in the olive oils that have been extracted , or enhance the shelf life of various plant oils , where the concentration of natural antioxidants is very limited . Pharmaceutical applications , focusing on their antibacterial properties are now being developed . Our laboratory specializes in membrane technology. Our particular task is to apply membrane operations, after appropriate pretreatment (possibly sedimentation), in order to obtain poly-phenol recovery from various effluents (from two phase or three phase olive oil milling factories). Various types of membranes and membrane unit operations (Microultra- and nanofiltration) will be applied in order to recover the important compounds, taking into account chemical compatibility, flux and retention factors. 1. INTRODUCTION The extraction and manufacture of olive oil in Greece, as well as, in other Mediterranean countries, are carried out in small plants which operate seasonally and as a byproduct generate olive oil mill wastewater (OMW), red to black, high conductive and acidic liquid effluent. Apart from its extremely high chemical oxygen demand (COD) value 50 to 150 g/L, OMW is known for its high toxicity due to the presence of polyphenols. The origin of polyphenols is the phenolic compounds, which are initially contained in to the olive fruits and preferentially pass in to the aqueous phase of the waste effluent. In their initial form the phenolic compounds are not dangerous, but they became so when the effluent is disposed of into evaporation ponds or is discharged into surface water receivers. During this disposal procedure the initial phenolic compounds create a pollutant potential by removal of the main toxic compounds. Over the last decade we have seen a gradual move from three – phase decanters to two – phase ones. The latter have been viewed as more environmentally friendly, since they use less amount of water. When two – phase decanters are used no liquid waste effluents are produced, The two streams, that exit the decanter are (i) one comprising of olive oil and (ii) the other one is the high moisture olive cake which is comprised of husks, seed oil and concentrated OMW. All of the liquid wastes typically encountered in the usual three - phase decanters are now part of the crude olive cake and they are present in a more concentrated form. The current practice is to ship the olive oil – mill cake to the closest olive kernel – oil-processing plant. In a nutshell, the environmental disposal problem of OMW is transferred from the mill to the olive kernel – oil-processing plant. The polyphenols are responsible for the dark color, phytotoxic effects and antibacterial activity. Increasing attention has been paid to discovering a use for OMW and a wide range of technological treatments are available nowadays for reducing their pollutant effects and for their transformations into valuable products. Technologies, which are able to treat OMW, are too expensive for the mostly small and medium size olive mills. Actually, only processes, based on unit operations and especially membrane processes could be used, especially when high additive value products are to be produced. 2. PHENOLIC COMPOUNDS IN OMW Olive oil is produced by mechanical pressure from olive paste, which is obtained by a process of milling and continuous washing with water (malaxation). This procedure yields a considerable amount of wastewater. Generally, OMW contains salts, associated with high biochemical oxygen demand (BOD), chemical oxygen demand (COD), lipids, pectins, polysaccharides and polyphenols. In this by-product there is the presence of natural antioxidants. HPLC analysis of the wastewater extract allows the separation of several components with antioxidant properties, identified as phenols and flavonoids. Among these are hydroxytyrosol, oleuropein, vanillic acid, and verbascoside. The wastewater contains notable levels of phenolic compounds, which could be utilized as antioxidant sources for fats and oils. The plant phenols are aromatic secondary metabolites that embrace a considerable range of substances possessing an aromatic ring bearing one or more hydroxy substituents. Phelolic compounds present in olives are conventionally characterized as ‘polyphenols” an unfortunate term since not all are polyhydroxy derivatives. In particular a number of compounds, namely cinnamic acid, elenolic acid, shikimic acid and quinic acid, are treated in the present discussion as phenolics because of metabolic considerations although they lack a phenolic group or even an aromatic ring. Plant polyphenols have been classified into 15 major groupings distinguished by the number of constitutive carbon atoms in conjuction with the structure of the basic phenolic skeleton (Table 1). The range of known phenolics is thus vast but of the various groups only the benzoic acids, cinnamic acids, flavonoids and iridoids are of major significance in olives. Additional structural complexity is introduced by the common occurrence of certain phenolics as the O – glycosides in which one or more of the phenolic hydroxy groups is bound to a sugar or sugars by an acid – labile hemiacetal bond. Glucose is the most commonly encountered sugar with rhamnose and the disaccharide, rutinose (6 – O-a-Lrhamnosyl-D-glucose) also encountered. Acylation of the glycosides in which one or more of the sugar hydroxys is derivatised with an acid, such as acetic or ferulic acid, is occasionally observed. Table 1: Major classes of fruit phenolic compounds in olives Number C atoms Basic skeleton Class Example 7 C6-C1 Benzoic acid Vanillic acid Protocatechuic acid 9 C6-C3 Hydroxycinnamic acids Caffeic acid 15 C6-C3-C6 Flavonoids Anthocyanins Flavonoids glycosides Cyanidin N of Iridoids Lignins Tannins Rutin Oleuropein All of the phenolic compounds possess several common biological and chemical properties; namely, antioxidant activity, the ability to scavenge both active oxygen species and electrophiles, the ability to inhibit nitrosation and to chelate metal ions, the potential for autoxisation, and the capability to modulate certain cellular enzyme activities. The phenolics in olives are now recognized for their antimicrobial activity, molluscicidal properties, their preventative role in dacus oleae infestations and resistance to ather parasite invasions. Phenolics in olives have attracted attention as antioxidants. More specifically, antioxidant activity in refined olive oil decreased in the series hydroxytyrosol, caffeic acid > burylated hydroxytoluene (BHT) > protocatechuic acid, syringic acid. The ecological problem is mainly due to the compounds of phenolic nature of OMW, which are responsible for the dark color, phytotoxic effects and antibacterial activity. In order to know which group of phenolics is involved in the resistance to and/or inhibition of biological treatments was investigated the separation by ultrafiltration technique, using membranes with a cutoff 8 and 60 kDa, three groups of aromatics. The F1 fraction is low molecular-mass (F1<8 kDa), F2 fraction is medium molecular-mass (8 kDa < F2 <60 kDa)and the F3 fraction is the high molecular-mass fraction (F3 > 60 kDa). Untreated F1 fraction contains three families of aromatic compounds which could correspond to simple phenolics, o- diphenols and monomeric flavoids in a first group, hydrolysable tannins in a second group and some condensed tannins and anthocyanins in the higher hydrodynamic volumes. F2 and F3 contain complex and darkly colored polyphenols such as ‘humic acid like’ compounds, that are made up by phenolic monomers as p-coumaric, benzoic acid derivatives and substituted phenoxyethanol. F1 fraction is well degraded by aerobic bacteria. Bioadegradation of high concentrations of simple and low molecular-mass phenolic compounds could be achieved by new isolated or genetically – engineered bacteria under optimized aerobic process technology. By contrast, high molecular – mass polyphenols are degraded particularly by white rot fungi, processes requiring longer treatment periods. Furthermore, the comparison of the biodegradation of the isolated fractions in continuous anaerobic digestion showed that the toxicity of F1appeared rapidly at HRT = 14.5 days as the methane yield decreased drastically. In this case, only low molecular – mass phelolics (smaller than about 800 D) can penetrate the cell membrane. This toxicity may possibly be eliminated by longer treatments and by increasing biomass concentration in the reactor. However, the mechanism by which high molecular – mass polyphenolics inhibit methanization is not known. Most of the published research on OMW treatment has dealt with the anaerobic treatment of OMW but failed due to the high phenolic content of OMW and their potential inhibition of methanogenic bacteria. This toxicity was attributed to low molecular – mass compounds such as phenolics and lipids without any experimental arguments. By contrast it was shown that colored compounds inhibited the anaerobic digestion of OMW in UASB reactors. The concentration of the high molecular – mass polyphenols depends on olive variety, cultivation system, maturity of the fruit, extraction processes used and particularly the time and mode of conservation of this waste before treatment. These high molecular – mass compounds should be removed completely or partially from OMW prior to treatment by aerobic activated sludge or anaerobic digestion. A pretreatment step is required using physico – chemical methods or fungi capable of decreasing the organic load and degrading or modifying the high molecular – mass phenolic compounds in OMW biotreatments. Physicochemical treatments such as decolorization through resin or coagulation – flocculation with Ca(OH)2 resulted in reducing the concentration of high molecular – mass colored compounds. The treatment of the phenolic compounds of OMW with membrane processes is shown to be a very successful method. With hydrophilic Microfiltration and Ultrafiltration membranes is it possible to separate the polyphenols. The challenge in the application of a membrane process in OMW is concentrated on the additional difficulty due to the presence of olive oil and the resulting problem of compatibility of the membrane material with the particular application. 3. ANALYTICAL METHODS Vegetation waters are stored at -25 0C. About 20 ml of them are let to defrost and fitered using a Buchner funnel apparatus. 5 ml of vegetation waters are mixed well with 5 ml sodium diethyldithiocarbamate(DIECA) 20 mg/l in methanol, to inhibit polyphenoloxidase and lipoxygenase activities. Solid Phase Extraction(SPE) is used to separate the phenolic compounds present in the water extract. In oder to activate the cartridge, 5ml of ethyl ether is let to pass and then 5ml of distilled water. Two milliliters of this mixture is added to a 5g/20ml C18 cartridge. To recover the phenolic compounds 600 ml of Ethyl ether as extraction solvent is used to pass through the cartridge under vacuum pressure. The eluate is collected and the organic solvent is evaporated in rotary evaporator at 350C. The residue is dissolved in 5ml of Methanol and stored at -200C until it is used. The concentration of total polyphenols in the methanolic extract is estimated with FolinCiocalteau reagent. The procedure consisted of addition of some drops of water, dilution of 0.1 ml or a suitable aliquot of the extract (up to 0.4 ml ) in a 10 mL volumetric flask, and addition of 0.25 ml of Folin - Ciocalteau. After 3 minutes, 1 ml of saturated (35 %) Na2CO3 solution was added. The content was mixed and diluted to volume with water. The extinction was measured after 1 hr at 725 nm against a reagent blank. Caffeic acid served as a standard for preparing the calibration curve ranging 0-100 μg/10 ml assay solution. The determination is done by spectrophotometer(UV-Visible) at 725 nm according to Gutfinger,T; Polyphenols in Olive Oils JAOCS. 4. MEMBRANE OPERATIONS The phenolic compounds contained initially in the vegetation waters are of a low molecular mass in a range which typically belongs to the Nanofiltration (NF) separation range. Polyphenols, as macromolecular substances, could be removed by Ultrafiltration (UF), phenols could be recovered by Nanofiltration. In our laboratory, we intend to use both membrane unit operations. Applying Ultrafiltration to a model system being an aqueous solution 1% (w/v) consisting of Water, 99% Caffeic acid SIGMA: C 0625 180 Da Vanillic acid, SIGMA: V 2250 168 Da Gallic acid SIGMA: G 7384 170 Da Tyrosol , EXTRASYNTHESE S.A. 138 Da Oleuropein: EXTRASYNTHESE S.A. 540 Da The model system will be exposed to ambient conditions in order to study the stability of the initial phenolic compounds with time. As the phenols will polymerize their molecular mass will increase and their retention by UF membranes The aim will be achieved by measuring the retention coefficient of the Ultrafiltration membrane as a function of time We have installed stirred cell modules (model 8200) made by Amicon and we are going to test plyethersulphone as well as PVDF membranes of a cutoff of 10 000 Da. Nanofiltration experiments aim at the direct recovery of low molecular mass phenols. A crossflow module will be useed in this case, since higher transmembrane pressures are required which cant be obtained with the stirred cell kind of modules. 1. 2. 3. The criteria of successful application are Permeate Flux Retention with the respect to various phenols Compatibility The last point is a critical point, especially for Nanofiltration membranes. Usually, commercial NF membranes are made of materials such as cellulosics or crosslinked nylon said to give compatibility problems with phenolic compounds. 5. POTENTIAL USES OF RECOVERED PHENOLIC COMPOUNDS The well known effect of the Mediterranean diet in lowering the incidence of several pathogenic pathologies , including heart diseases and cancer is greatly contributed to the use of extra virgin olive oil and the presence of a large amount of dietary antioxidants , known with the generic name phenolic compounds. Phenolic compounds , apart from product stability and extended shelf life , exert a variety of biochemical and pharmacological roles including anti-inflammatory and anti-neoplastic activities , making olive oil a unique fruit . . It is clear that the recovery of poly-phenols from OMW ,would make these compounds valuable precursors in the pharmaceutical ,chemical and food industries (Recently , the biggest olive producer in Greece , has launched a new type of olive oil highly enriched in poly-phenols) . At the same time , classical biological processes designed for reducing COD , nutrients and microbiological load will be accelerated . References Danielle Ryan and Kevin Robards (1998) “Phenolics compounds in olives” Analyst, May 1998, Vol.123 (31R –44R) 2. I Angelikaki, B.K. Ahring (1997) “Codigestion of olive oil mill wastewaters with manure, household waste or sewage sludge” Biodegradation 8:221-226, 1997, Kluwet academic publishers, printed in the Netherlands. 3. J.Κ. Scott, J.O. Oloidi, I.F. McConvey “Emulsion membrane filtration applied to phenol recovery” Process technology group, ICI FCMO, Hexagon house, Blackley 1. Κουτσαυτάκης Α. Στεφανουδάκη Ε. (1994) “Ελαχιστοποίηση αποβλήτων με ελαιουργεία δυο φάσεων” Πρακτικά διεθνούς διημερίδας Σητεία 16-17 Ιουνίου 1994, Γεωτεχνικό επιμελητήριο Ελλάδος, Οργανισμός ανάπτυξης Σητείας 5. Οικονόμου Δ., Κουτσαυτάκης Α., Στεφανουδάκη Ε.(1994) “Αξιοποίηση αποβλήτων ελαιουργείων με τεχνολογία μεμβρανών” Πρακτικά διεθνούς διημερίδας Σητεία 16-17 Ιουνίου 1994, Γεωτεχνικό επιμελητήριο Ελλάδος, Οργανισμός ανάπτυξης Σητείας 6. N. Ινιωτάκης, Σ. Μαράκης, Π. Μιχαηλίδης(1994) “Μια συμφέρουσα εγκατάσταση διαχείρισης του ελαιολάδου” Πρακτικά διεθνούς διημερίδας Σητεία 1617 Ιουνίου 1994, Γεωτεχνικό επιμελητήριο Ελλάδος, Οργανισμός ανάπτυξης Σητείας 7. Ν. Καλογεράκης, Ε. Διαμαντόπουλος, Α. Γυπάκης (2000) ”Ολοκληρωμένη διαχείριση υγρών αποβλήτων ελαιοτριβείων στην Κρήτη” Workshop on Energy from Wastes: Enviromental and Agricultural Advantages, 17/04/00)) 8. Maurizio servili, Maura Baldioli, Roberto Selvaggini, Enrico miniati, Alceo Macchioni and Gianfrancesco Montedoro (1999) “High perjormance liquid chromatography evaluation of phenols in olive fruit, virgin olive oil, vegetation waters, and pomace and 1D- and 2D- Nuclear magnetic resonance characterization” JAOCS, Vol. 76. no.7 9. Sami Sayadi, Noureddine Allouche, Mohamed Jaoua, Fathi Aloui, (1999) “Detrimental effects of high molecular mass polyphenols on olive mill wastewater biotreatment” Process Biochemistry 35 (2000) 725-735 10. Στέλλιος Τσόνις, Βασιλική Τσόλα, Σωτήριος Γρηγορόπουλος (1989) “Systematic characterization and chemical treatment of olive oil mill wastewater” Toxicological and environmental chemistry, Vols.20-21, pp.437-457, Gordon and Breach, Science publishers, Inc. Printed in Great Britain. 11. Στεφανουδάκη-Κατζουράκη Ε., Α. Κουτσαυτάκης (1994) “Χαρακτηριστικά αποβλήτων από ελαιουργεία δυο και τριών φάσεων” Πρακτικά διεθνούς διημερίδας Σητεία 16-17 Ιουνίου 1994, Γεωτεχνικό επιμελητήριο Ελλάδος, Οργανισμός ανάπτυξης Σητείας 4.