assistant manager - IndiaTravelMaster.com

advertisement

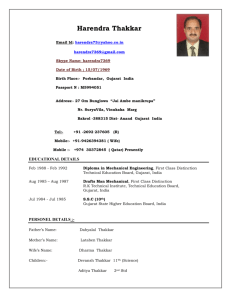

www.seafarerjobs.com For any other query contact us at info@seafarerjobs.com Resume ID No. 21067 Shibly Ahamed.V.J, E-mail : skull.lion@yahoo.com, Tel: 04328-244926, Mobile: +919894621944. CAREER OBJECTIVE: To integrate my professional qualification, skills and work experiences in Technology and leading to the value additions to the organizational goals, always capable of fulfilling the requirements of the company which hires me and making the company feels happy that I am delivering above expectations. As a fresher seeking for Assistant Watch keeping engineer on a merchant ship or relevant, Besides having completed the required pre-sea courses and certification for going to sea as an assistant to the Engineer in charge of watch, I can undertake most of the tasks the ship’s Chief Engineer would like to their juniors to carry out such as: Recognize and put to use the various hand tools and machine tools available in an engine room. Dismantle, clean and pressure test heat exchanger, shell and tube type and plate type. Carry out necessary check before starting a diesel generator set, Empty, clean, pressure test and recharge a portable fire extinguisher. ACADEMIC PROFILE : Graduate in Mechanical Engineering – GME(MARINE) - CHIDAMBARAM INSTITUTE OF MARITIME TECHNOLOGY ( Year 2010 – 2011 ) Bachelor of Engineering in Mechanical – B.E (MECH) - J.J.COLLEGE OF ENGINEERING & TECHNOLOGY - Anna university ( year 2005 – 2009 ) CERTIFICATIONS AND TECHNICAL COURSES : Certification(STCW) : Elementary First Aid (EFT), Personal Survival Techniques (PST), Fire Prevention & Fire Fighting (FPFF), Personal Safety & Social Responsibilities (PSSR). DCE approved (upto 2016): Chemical Tanker Familiarization (CTF), Oil Tanker Familiarization (OTFC), Liquefied gas Tanker Familiarization (LGTF). Computer Course: MS - Office Automation, Auto-cad, Pro-E and Ansys. ORIENTATION TRAINING: Organization Duration : Covanta Madurai Operating [P] ltd – INDIA – Madurai, : 13th Dec 2010 to 05th Feb 2011, TRAINED PLANT CAPACITY: Wärtsilä Diesel engine - 15x7=106MW (V-Type 18 cylinder) ENGINE PARTS – Cylinder head(Rocker Arm, yoke rod, inlet & exhaust valves, valve seat,etc.,),Fuel injector, Fuel pump, Turbocharger(swirlEx),Charge air cooler, High pressure pipe, Liner, Piston, Flywheel, Alternator, Connecting rod, Crank shaft, Cam shaft, Servomotor, etc., JOB DESCRIPTION: Checking and maintaining the fuel pump of the diesel engine. Buffing, Cleaning and lapping the cylinder head. Dismantling and assembling the fuel injector of the diesel engine. Checking the proper flywheel alignment. Checking and maintaining the High pressure pipe on daily basis. Servicing the diaphragm pump and various other pumps. Dismantling and assembling of valves. Maintenance the Charge Air Cooler. Monitoring the diesel engine room. Sending the performance report to the higher management. OBJECTIVE: STRESSES IN BOILER SHELLS – Circumferential stress, longitudinal stress, Tensile test, Rivet bars, bend test. AUXILIARY BOILERS – Scotch boilers, Cochran boiler (smoke tube and spheroid vertical), Clarkson thimble tube boiler, Spanner vertical smoke tube boiler, Aalborg vertical water tube boiler, Forced circulation boiler, Typical package boiler, Dual pressure boiler, Forced circulation type and composite boiler, exhaust gas unit. WATER TUBE BOILERS – Steam drum, Water drum, Headers, Generating tubes, Screen tubes, Water wall tubes, Down comers tubes, Riser or Return tubes, Super heater tubes, Super heater support tubes, ESD 1,11,111 Types. SUPERHEATERS AND UPTAKE HEAT EXCHANGERS – Rising the boiler pressure, Superheating the steam, Water cooled and air cooled attemperator, Surface and spray type De super heaters, Vertical and horizontal tube types. BOILER MOUNTINGS – Safety valves, Main stop valve, Auxiliary stop valves, Feed check valves, Boiler feed water regulator, Water level indicators, Low water alarms, Blow down valves, Scum valves, Drain valves, Air vents, Super heater circulating valves, Chemical dosing valves, Salinometer valves, Shoot blower master steam valves and pressure gauge connections. COMBUSTION OF FUEL IN BOILERS – Primary flames, Secondary flames, Fuel oil burner types, Air register, Fuel oil system, Fire bricks, Monolithic refractories and shoot blower. BOILER OPERATION – Rising steam, Inspections of opening up and boxed up, Hydraulic testing, Corrosion, Erosion, Overheating, Cracking, Mechanical damage, Internal cleaning and external cleaning. PERSONAL DETAILS: Name Father’s name Date of Birth Place of Birth Marital status Nationality Religion Linguistic Proficiency Address : : : : : : : : : Contact Phone / Email : V.J.Shibly Ahamed E.Jafar Khan 09th JUNE 1988 Labbaikudikadu Single Indian Islam English, Hindi & Tamil Shibly Ahamed.V.J, 114/26A, Jailani Street, Labbaikudikadu. Perambalur (Dt.), Kunnam (Tk.), Pin code: 621108. Tel: 04328-244926, Mobile: 9894621944, Email: skull.lion@yahoo.com. 04328-244926/skull.lion@yahoo.com Passport Number Date of Issue Date of Expiry Place of Issue : : : : F0187416 27/07/2004 26/07/2014 Tiruchirappalli CDC DETAILS: CDC Number Date of Issue Date of Expiry Place of Issue : : : : MUM 181508 04/01/2011 03/01/2021 Mumbai INDoS Number Visa Status : : 10EL1304 Visit visa PASSPORT DETAILS: STRENGTH: Self confident, Capable to overcome any kind of problems. Good English Communication, Active participation in association function. Interested in Swimming and Cycling. DECLARATION: Hereby I declare that the above given information are to the best of my knowledge. Place: Date: (J.SHIBLY AHAMED)