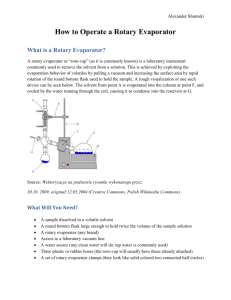

Rotary Evaporator - School of Chemistry

advertisement

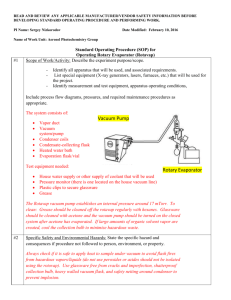

STANDARD OPERATING PROCEDURE SP # APM002 Version: 1.0 Date: 06/07/10 Revise by: 06/07/13 Page 1 of 9 Replaces: N/A Written by: Dana Lee Morgan Authorised by: Rachel A. Caruso Advanced Porous Materials Laboratory, School of Chemistry, The University of Melbourne USE OF ROTARY EVAPORATOR (BUCHI R215) 1. Introduction This SOP discusses the procedure and safety guidelines for the use of the Buchi R215 Rotary Evaporator coupled with a Lauda RA 12 recirculating chiller. A rotary evaporator is a device used in chemical laboratories for the efficient and gentle removal of solvents from samples by evaporation. The solvent is evaporated in a reduced pressure environment with the application of heat and constant rotation. The reduced pressure increases the evaporation process by decreasing the boiling point of the solvent, allowing the evaporation to be conducted at lower temperatures. Rotation of the evaporation process maintains homogeneous heating of the solvent whilst increasing the available surface area of the evaporating solvent. Rotation also reduces the effect of ‘bumping’, the sudden burst of solvent vaporisation that can scatter liquid exposed to reduced pressure. 2. Scope This procedure applies to all staff, students and visitors of the Advanced Porous Materials Group in the School of Chemistry at the University of Melbourne that work in the laboratory and have the potential to use the rotary evaporator. 3. Safety Only trained laboratory personnel may operate the instrument. In the event of a power failure, the evaporation flask and condenser assembly will automatically be raised from the water bath. Risk of implosion or explosion: When a vacuum exists within glassware there is a risk of implosion with potential hazards of flying glass, spattering chemicals and fire. Although glass vessels are frequently used in vacuum systems, they can implode of explode violently, either spontaneously from the strain or from an accidental blow. Implosion and flying glass can lead to cuts and lacerations. Any piece of glassware has the potential to do harm following implosion. Use only glassware that is free from cracks, scratches, etching marks and other imperfections. Use only quality, heavy walled glass or Pyrex® round bottom flasks or specially manufactured accessory flasks (e.g. beaker flask) for evaporation. The condenser and receiving flask have been plastic coated to restrain fragments in case of implosion. Plastic safety netting may also be placed around the condenser. STANDARD OPERATING PROCEDURE SP # APM002 Page 2 of 9 Version: 1.0 Date: 06/07/10 Revise by: 06/07/13 Replaces: N/A Written by: Dana Lee Morgan Authorised by: Rachel A. Caruso Advanced Porous Materials Laboratory, School of Chemistry, The University of Melbourne Flasks with volumes of 1 litre or larger must be enclosed in tape or plastic mesh to restrain fragments in case of implosion. Glass dewars should be fully wound in tape or preferably enclosed in a metal container. The properties of compounds used must be investigated prior to evaporation or reaction. Certain compounds are explosive upon dryness. General safety precautions: Personal protective equipment (PPE) including safety glasses or face shield and laboratory coat must be worn to protect against the hazards of vacuum procedures. The rotation speed and application of vacuum should be done gradually when using a rotary evaporator. Do not hold onto sample whilst it is revolving: failure of the flask could result in serious lacerations to the hands. Only heavy-walled, vacuum grade rubber tubing shall be used for the application of vacuum. Thin-walled rubber tubing and plastic tubing is not suitable because they collapse leaving a partially closed system. The length of the vacuum tubes should be as short as practicable and do not require to be secured with cable ties. Quality silicone tubing shall be used for the cooling water which must be secured to the screw fittings with cable ties All tubing shall be checked regularly and replaced when brittle. Large volumes of organic solvent vapour can be generated through rotary evaporation. When in use, the condenser should always be cooled. Clean the apparatus after use. Do not mix halogenated and non-halogenated solvents in the receiver. 4. Licences and Permits N/A 5. Training and Competency The trainee must have already mastered an understanding of and have been given the instruction in the use of rotary evaporation by the instrument supervisor. Competency will be assessed by close observation of the trainee by the instrument supervisor or an approved trainer. The training and competency records are to be filed and stored in the Advanced Porous Materials Laboratory Safety Folder. 6. Risk Assessments Refer to the following risk assessment forms: Use of rotary evaporator (Buchi 215) and recirculating chiller (Lauda RA 12), assessed 19/11/09. STANDARD OPERATING PROCEDURE SP # APM002 Page 3 of 9 Version: 1.0 Date: 06/07/10 Revise by: 06/07/13 Replaces: N/A Written by: Dana Lee Morgan Authorised by: Rachel A. Caruso Advanced Porous Materials Laboratory, School of Chemistry, The University of Melbourne 7. Use of rotary evaporator, assessed 23/11/09. Use of glassware under vacuum, assessed 05/01/09. Use of glassware, assessed 09/11/09. Use of electrically operated equipment, assessed 20/06/07. Waste solvent disposal, assessed 09/11/09. Equipment and Maintenance / Handling and Storage / Labelling The Buchi Rotavapor® R-215 communicates digitally with the heating bath, vacuum controller and vacuum pump. A Woulff bottle is attached between the rotary evaporator and the vacuum pump to minimise vapour contamination of the pump. The vacuum controller is enabled when either the rotary evaporator or vacuum pump is switched on. Under standard operation, do not turn the vacuum controller power switch off. The Lauda Alpha R12 recirculating chiller is operated separately, and it is recommended to commence cooling the heat transfer medium prior to any evaporation or reflux process. Maintenance: Rotary Evaporator: Clean housing regularly with a moist cloth (Do not use cleaning agents). Regularly check tube connections. Replace tubes when they show signs of cracking or brittleness. Grease all joints on the condenser regularly. Clean seals regularly with water. Dry with a soft cloth. Seals should be replaced if they exhibit signs of wear and tear. Clean the inner surface of the heating bath if calcification or light rust spots are observed. To clean, empty the heating bath and clean accordingly. Rinse the bath thoroughly afterwards. o Minor calcification: Use a non-abrasive cleaning agent. o Stubborn calcification: Use acetic acid to remove. o Rust spots: Gently remove with Scotch-Brite. Rinse glassware with water and a mild cleaning agent. An alkaline cleaner may be used to remove particulate build-up. Remove any grease from joints. Clean all glass components manually. Check glass components regularly for imperfections, cracks, scratches, etc. Heat transfer medium: Pure deionised water should not be used as the heat transfer medium in the water bath of the chiller due to the corrosive nature towards stainless steel. When pure deionised water cannot be avoided, the addition of 1–2 g borax (Na2B4O7∙10 H2O) per litre water is mandatory. The chiller heat transfer medium should contain an adequate ratio of coolant (ethylene glycol) to sufficiently lower the freezing point so that ice does not form within the bath or recirculator. STANDARD OPERATING PROCEDURE SP # APM002 Page 4 of 9 Version: 1.0 Date: 06/07/10 Revise by: 06/07/13 Replaces: N/A Written by: Dana Lee Morgan Authorised by: Rachel A. Caruso Advanced Porous Materials Laboratory, School of Chemistry, The University of Melbourne Coolant has been added to the chiller in a ratio of 1:2 with tap water. The chiller has a capacity of 12 L. This ratio sufficiently reduces the freezing point of the heat transfer medium to below –10 °C, allowing for safe operation of the chiller down to –5 °C. A ratio of upto 1:4 may be used if the chiller is not to be operated below 0 °C. If the instrument requires servicing, please contact: In Vitro Technologies Pty. Ltd 7–9 Summit Road, Noble Park, Victoria 3174 Tel: +61 1300 156 862 www.invitro.com.au Storage When not in use please cover the rotary evaporator with a dust cover, empty the water bath and cover. Ensure that the chiller lid is in place. 8. Operating Procedures Evaporation/Distillation Processes: 1. Ensure that fluid levels in the recirculating chiller and water bath are adequate prior to use. Neither apparatus should be powered unless they contain a heat transfer medium. 2. Remove all dust covers from the instrument. 3. Switch on all instrument components at the power point. 4. Switch on the recirculating chiller prior to commencing any operations on the rotary evaporator so that the coolant fluid may reach the required temperature. The chiller is directly connected to the condenser. 5. Switch on the rotary evaporator, vacuum pump and heating bath (green switches). The vacuum controller will automatically power up when either the rotary evaporator or vacuum pump is turned on. Allow sufficient time for the water bath to heat up to the desired temperature (10–15 min). Water bath temperature can be controlled directly by turning the adjusting knob during operation. Clockwise to increase temperature, anticlockwise to decrease the temperature. 6. Attach the collection flask to the base of the condenser and secure with the screw clip. 7. Attach the bump trap to the vapour duct, securing with the combi clip. If drying samples with negligible solvent volume, the bump trap may be omitted and the evaporation flask may be attached directly to the vapour duct and secured with the combi clip. 8. Attach the evaporation flask (e.g. round bottom flask, beaker flask) to the bump trap and fasten with a Keck clip (red, size 29). Check Keck for cracks. Replace if necessary. 9. Slowly start rotation of the flask and gradually increase the speed. 10. Press the green start button on the vacuum controller. (The vacuum controller is set to 800 mbar in the Manual mode.) 11. Once the sample has stabilised, lower the flask into the water bath. STANDARD OPERATING PROCEDURE SP # APM002 Page 5 of 9 Version: 1.0 Date: 06/07/10 Revise by: 06/07/13 Replaces: N/A Written by: Dana Lee Morgan Authorised by: Rachel A. Caruso Advanced Porous Materials Laboratory, School of Chemistry, The University of Melbourne 12. Slowly increase the vacuum by rotating the vacuum controller selection knob anticlockwise, watching for signs of bumping (bubbles) and increase pressure (clockwise) if necessary. Continue increasing the vacuum until the desired vacuum is attained. 13. Continue the process as long as necessary. 14. When the distillation/evaporation process is complete, raise the evaporating flask from the water bath, reduce the rotation speed, support the stationary flask with your hand and then press the red stop button on the vacuum controller TWICE to vent the vacuum. 15. Remove the evaporation flask, bump trap and receiving flask. Discard solvent if necessary into the correct waste collection bottle. 16. Allow the chiller to recirculate for a further 5 min before switching off. 17. Once complete, switch off all components (aside from vacuum controller) at both the instrument (green switch) and the power point. 18. Clean all glass components, including the bump trap and allow to air dry. Leave the collection flask unattached from the condenser and place on the moulded holder. 19. Replace dust covers on instrument. Reflux/Synthesis Processes: Reflux/synthesis processes may be performed with the glass assembly on this rotary evaporator. To perform reflux/synthesis processes, the shut-off tab, located on the distribution head (glassware linking the vapour duct to the condenser) should be wound down until a seal is formed against the receiving flask outlet. This effectively shuts off the receiving flask, allowing condensed vapour to travel back down the vapour duct into the evaporating flask. Teflon tubing can be attached to the ground glass stopcock and to the outlet on the distribution head (located at the receiving joint of the stopcock) so that extra solvent may be added to the ongoing reaction. The standard operating procedure for reflux/synthesis processes is the same as for evaporation/distillation processes, with the exception of omitting the bump trap. Operation of the Vacuum Controller The V-850 Vacuum Controller may be operated manually or automatically through the use of the solvent library. 1. Switch on vacuum controller. 2. Select the desired mode (Manual or Solvent Library ) 3. To start vacuum; press the green start button. 4. To stop vacuum; press the red stop button twice. Manual Operation: Switch on vacuum controller. Press the menu button P Set. If not in the manual mode, change to this mode. Select the pressure set point using the selection knob. Clockwise to increase the value or counter clockwise to decrease the value. To confirm press OK. STANDARD OPERATING PROCEDURE SP # APM002 Page 6 of 9 Version: 1.0 Date: 06/07/10 Revise by: 06/07/13 Replaces: N/A Written by: Dana Lee Morgan Authorised by: Rachel A. Caruso Advanced Porous Materials Laboratory, School of Chemistry, The University of Melbourne During operation, the pressure can be altered by rotating the selection knob clockwise or counter clockwise as required. Solvent Library: Switch on vacuum controller. Press the library button (). The solvent library screen opens. Use the selection knob of the vacuum controller to scroll through the solvent library. Select the highlighted solvent by pressing OK. The library proposes the heating bath temperature. This temperature can be set at the heating bath, or conversely, this temperature can be altered on the vacuum controller. The selection knob is used to alter the temperature and changes are authorised by pressing OK. To confirm the settings, press Accept. Operation of the Chiller: When powered, the chiller will immediately recirculate the heat transfer medium and commence heating or cooling to the set temperature. To set operational temperature: 1. Switch on chiller. 2. Press yellow enter key until SET is displayed on the LCD screen. Press the red button to increase or the blue button to decrease the setpoint temperature. To accept the temperature, press the yellow enter key (). 9. Controls and Calibrations This instrument or any component of this instrument is to be used to calibrate other equipment. No component of the rotary evaporator requires calibration. The thermostat of the chiller may be calibrated. Please refer to the LAUDA Alpha manual for details relating to calibrating the temperature probe. 10. Waste Disposal Solvent Disposal: Dispose of solvents in the appropriate waste container (e.g. water soluble waste solvent, water insoluble waste solvent, halogenated waste solvent). Glass Disposal: All broken, irreparable glassware should be rinsed and disposed of in the designated glass bin. Coolant Disposal: Place waste coolant into an appropriate sealable plastic vessel which has not been used to store other materials. Label the vessel clearly. Send for waste disposal/recycling. 11. Relevant Documents / References STANDARD OPERATING PROCEDURE SP # APM002 Page 7 of 9 Version: 1.0 Date: 06/07/10 Revise by: 06/07/13 Replaces: N/A Written by: Dana Lee Morgan Authorised by: Rachel A. Caruso Advanced Porous Materials Laboratory, School of Chemistry, The University of Melbourne Buchi Operation Manuals: Rotavapor® R-210/215, Version C (093076 en) Vacuum Pump V-700/710, Version C (093091 en) Vacuum Controller V850/855, Version A (093081 en) Lauda Operation Manual: LAUDA Alpha, C-Version (YACC0085) Risk assessments applicable to the SOP are listed in Section 6. 12. Signage / Summaries / Templates Competency Training Records Form – Attached, see page 8. Copies of this form are to be stored and filed and in the Advanced Porous Materials Laboratory Safety Folder. 13. Appended Material N/A STANDARD OPERATING PROCEDURE SP # APM002 Version: 1.0 Date: 06/07/10 Revise by: 06/07/13 Page 8 of 9 Replaces: N/A Written by: Dana Lee Morgan Authorised by: Rachel A. Caruso Advanced Porous Materials Laboratory, School of Chemistry, The University of Melbourne ADVANCED POROUS MATERIALS LABORATORY COMPETENCY TRAINING RECORDS – ROTARY EVAPORATOR (BUCHI R215) Date Name University/Dept. Trainer Competency Date Trainee Trainer STANDARD OPERATING PROCEDURE SP # APM002 Page 9 of 9 Version: 1.0 Date: 06/07/10 Revise by: 06/07/13 Replaces: N/A Written by: Dana Lee Morgan Authorised by: Rachel A. Caruso Advanced Porous Materials Laboratory, School of Chemistry, The University of Melbourne