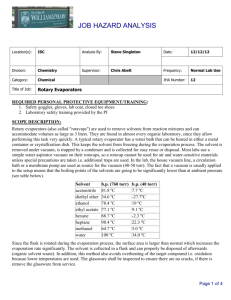

Rotary Evaporator (Rotavap) SOP - Safety & Procedures

advertisement

READ AND REVIEW ANY APPLICABLE MANUFACTURER/VENDOR SAFETY INFORMATION BEFORE DEVELOPING STANDARD OPERATING PROCEDURE AND PERFORMING WORK. PI Name: Sergey Nizkorodov Date Modified: February 10, 2016 Name of Work Unit: Aerosol Photochemistry Group #1 Standard Operating Procedure (SOP) for Operating Rotary Evaporator (Rotavap) Scope of Work/Activity: Describe the experiment purpose/scope. - Identify all apparatus that will be used, and associated requirements. List special equipment (X-ray generators, lasers, furnaces, etc.) that will be used for the project. Identify measurement and test equipment, apparatus operating conditions, Include process flow diagrams, pressures, and required maintenance procedures as appropriate. The system consists of: Vapor duct Vacuum system/pump Condenser coils Condensate-collecting flask Heated water bath Evaporation flask/vial Vacuum Pump Test equipment needed: Rotary Evaporator House water supply or other supply of coolant that will be used Pressure monitor (there is one located on the house vacuum line) Plastic clips to secure glassware Grease The Rotavap vacuum pump establishes an internal pressure around 17 mTorr. To clean: Grease should be cleaned off the rotavap regularly with hexanes. Glassware should be cleaned with acetone and the vacuum pump should be turned on the closed system after acetone has evaporated. If large amounts of organic solvent vapor are created, cool the collection bulb to minimize hazardous waste. #2 Specific Safety and Environmental Hazards: State the specific hazard and consequences if procedure not followed to person, environment, or property. Always check if it is safe to apply heat to sample under vacuum to avoid flash fires from hazardous vapors/liquids (do not use peroxides or azides should not be isolated using the rotovap). Use glassware free from cracks and imperfection, shatterproof collection bulb, heavy walled vacuum flask, and safety netting around condenser to prevent implosion. #3 Describe in detail how the hazards will be controlled. a. Identify the Engineering Controls (e.g. interlocks, shielding), Standard Operating Procedures, or Personal Protective Equipment (e.g. respirators, gloves;) that will be employed to reduce hazards to acceptable levels. Active engineering controls include: Power switch and dial to control the temperature of the water bath. Power switch and dial to control the speed of the rotating flask. Power switch on vacuum system to turn on the pump. Motor controlled switch to adjust the level the vacuum flask is submerged in the bath. Power switch on coolant supply. Valves on condenser control internal pressure imprecisely (release or apply vacuum). Passive engineering controls include: Waste is cooled in condenser by the condenser coils and is collected in the collection flask or trap that can be discarded. b. Address emergency shutdown procedures. Possible emergencies: explosion or implosion. Cause for explosion: Materials being isolated using the rotovap are not thermally stable or cannot be placed under vacuum. Cause for implosion: Broken/damaged glassware placed under vacuum. Do the following: Always wear personal protective equipment: safety glasses, long sleeves and closed toed shoes. Turn off the vacuum system and hot water bath. Turn off the rotating flask Release the internal vacuum by opening the valve to room air on the condenser. If you are hurt from either an explosion or implosion, seek medical attention immediately. #4 **Be sure to keep long hair tied back to prevent pulled hair by the rotating mechanism. Designated Area: Indicate the designated area for performing this process in the laboratory. Room 385 is currently where the Rotavap is located for use. #5 Personal Protective Equipment (PPE): State the personal protective equipment selected and required. Examples: safety spectacles, work gloves, respiratory protection, steel toe shoes. Personal protective equipment includes: #6 All people in the vicinity of the operating rotovap must wear safety goggles. All people in the vicinity of the operating rotovap must wear closed toe shoes. All people in the vicinity of the rotovap must wear long sleeves. Gloves should be worn by the person operating the Rotavap. Long hair should be tied back by the person operating the Rotavap. Important Steps to Follow: List the specific sequence staff should follow to avoid hazard. Refer to the instrument manual for the start up and power down procedures. A short version of these procedures is provided at the end of this document. #7 Emergency First Aid Procedures: a. Describe immediate medical treatment required in case of personnel exposure. -Complete online incident report form at www.ehs.uci.edu If someone is hurt by an explosion or implosion during use of the rotovap: #8 Make an appointment with a physician if they have minor injuries. Take the person to the emergency room if they have more severe injuries, including burns, cuts, etc. Training & Competency Requirements: Describe necessary training and demonstration of competency for performing the hazardous operation. Everyone operating the rotovap must: #9 Pass basic laboratory safety training Read this SOP Identify waste stream and disposition of unused stock of chemicals List concentrations and amounts of hazardous wastes or emissions and control measures. Additional guidelines regarding hazardous waste at : http://www.ehs.uci.edu/programs/enviro/ Large amounts of organic solvent vapors are considered hazardous waste. Do not isolate peroxides, azides or other thermally unstable compounds via the rotovap. #10 Decontamination and spill clean-up procedures Clean up organic waste with paper towels and Kim wipes. Wipe with area with acetone. Other hazardous waste spills should be isolated and EH&S should be contacted. As the Principal Investigator, it is your responsibility to ensure that all individuals listed in this protocol is taught correct procedures for the safe handling of hazardous materials involved in this study. It is also your responsibility to assure that your personnel attend Lab Core Safety Training and other applicable safety training courses. Both PI and all persons associated with the protocol must sign the following acknowledgement: I have read, asked questions, and understand the hazards of and safe working procedures for the activity/materials described herein. PI Signature: DATE Other Personnel: Name/ Signature DATE Name/Signature DATE Name/Signature DATE Standard Operating Procedures for Rotavap Last updated on June 22, 2011 PPE: Gloves, long sleeves/lab coats, closed toe shoes, long-hair to be tied back Turning Rotavap On: 1. Flip switch at the bottom of the water bath to heat water. Add more water into the water bath if sample does not touch the water. 2. Use the dial to adjust to water temperature. 3. Flip green switch on the top of the Rotavap to turn on the instrument. 4. Turn the dial next to the on/off switch to adjust rotating speed. Evaporating Sample: 1. Make sure vacuum is turned off and the Rotavap is in equilibrium. 2. Attach round bottom flask to the neck. Periodically grease the joints on the glassware .because the grease will evaporate and decrease evaporation efficiency. 3. Close the valve located on the left side of the condenser. 4. Turn on vacuum. Adjusting position of round bottom flask 1. Lower the round bottom flask into the water bath with the gray button on the front handle. 2. Pull gray knob in the center of the Rotavap to adjust the angle of the round bottom flask. Removing Sample from Rotavap after Evaporation 1. Turn vacuum off. 2. Open valve to air. 3. Remove round bottom flask once the Rotavap is at equilibrium. Turning off Rotavap 1. Flip switch on Rotavap and water bath off. The Rotavap will automatically go back to its original height.