Removal of Residual Solvents

advertisement

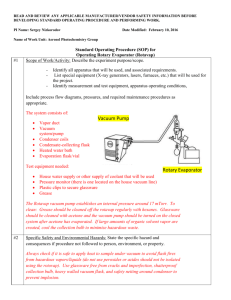

Removal of Residual Solvents Method by vacuum materials Water pump (1) Vacuum gauge (optional) (2) Vacuum dryer (3) Water bath (4) Heating (electric) (5) Silicone grease (to vacuumor hard Vaseline) (6) Non-stick container (silicon shields) adapted to the volume of distillate (7) Wash bottle (8) To avoid crushing, the pipe connections are in for vacuum (thick-walled) gas pipes can be used Connect all parts according to the diagram below The gauge is not necessary, in this case a valve is placed at the site and it shall be vacuum stabilizer The diameter of the water bath should be less than the diameter of the base of the dryer Note: For a homogeneous boiling water bath, add some glass beads (beads) (4) To prevent backflow of water, add a wash bottle (8) in the vacuum circuit Procedure: 1 - Testing of the operating temperature and vacuum adjustment Before the true distillation, test with the solvent alone In a cup (7) identical to the one used to add a small amount of pure solvent (25 ml / 1 oz)) Place it in the dryer Place the dryer in the bath and connect the vacuum hose Heat the water bath (to + / - 320 ° Kelvin) then start the vacuum When the solvent begins to boil adjust the water flow (or adjust the drain valve (2) The system is in equilibrium when a slight boiling solvent appears (small bubbles) Measure the temperature of the water bath These settings must be done once. 2 - Real Distillation Preheat water bath AND the dryer to the temperature measured during the test (item 1) Place a cup containing the distillate in the dryer Place a second cup with the same volume of solvent alone in the dryer (control) Close and connected to the vacuum circuit Maintain heating and vacuum 30 minutes AFTER the total evaporation of the solvent in the control container For a easy and complete recovery of oil put the cup in the freezer