4 The Forms - PSMS - Pesticide Stock Management System

advertisement

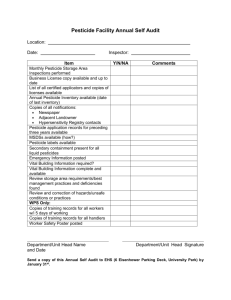

Instructions The Use of the New Inventory Forms Prepared by: Richard Thompson Waste Management & Environmental Consultant for Mark Davis UNFAO Rome Version 1.05 31 December 2005 Instruction for Use of Inventory Forms Table of Contents 1 Introduction .................................................................................................................... 1 2 Undertaking an Inventory Site Inspection ....................................................................... 1 2.1 Planning and Preparation .......................................................................................... 1 3 Definitions ...................................................................................................................... 2 3.1 Site ............................................................................................................................ 2 3.2 Store .......................................................................................................................... 3 3.3 Site information and Store information ....................................................................... 3 4 The Forms ..................................................................................................................... 3 The forms are made up of the following components: ....................................................... 3 4.1 Combined Site, Store and Risk analysis questionnaire .............................................. 3 4.2 Supplementary Store and Risk Analysis Questionnaires ........................................... 4 4.3 Material Forms........................................................................................................... 4 5 Site inspection and completion of forms ......................................................................... 4 5.1 On journey to site ...................................................................................................... 6 5.2 Arrive at site and meet key personnel ........................................................................ 7 5.3 Start completing the Store Forms with the site information during the meeting with the responsible person .............................................................................................. 7 5.4 Site plan .................................................................................................................... 8 5.5 Store information and plan......................................................................................... 8 5.6 Internal store plan ...................................................................................................... 9 5.7 Inventory of the materials in the store ........................................................................ 9 5.8 Completion of a store's inventory ............................................................................. 18 5.9 Other pesticide stores at the site ............................................................................. 19 5.10 Wrap-up .................................................................................................................. 19 6 Retention and transport of the completed forms and samples ..................................... 19 7 Data Entry .................................................................................................................... 19 Instruction for Use of Inventory Forms Inventory Documentation 1 Introduction FAO has developed an integrated system for recording and managing data from the inventory process. The system involves 3 process steps: 1. Undertaking the inventory and recording the information on specially designed paper forms 2. Entering the data from the paper forms into the Obsolete Pesticides Management System (OPMS), the online database for inventory data. The paper forms and OPMS are designed to facilitate easy and accurate data entry. 3. Assessing the stores and identifying those that are priorities for subsequent activities, such as safeguarding and disposal. OPMS incorporates the Environmental Management Toolkit and can automatically calculate the risk factors for each store, and compare them to identify the critical sites. OPMS is planned to be developed further to incorporate stock management systems such that the safeguarding and disposal activities can be recorded and monitored. This document primarily focuses on the use of the paper forms to undertake the inventory at sites and stores where pesticides are or have been stored. 2 Undertaking an Inventory Site Inspection The steps involved in undertaking an inventory site inspection are as follows: 1. Planning and preparation 2. site inspection, and completion of inventory paper forms 3. safe custody and consignment of forms and photo files to central office for data entry 2.1 Planning and Preparation Planning includes all the arrangements to organise the timing and logistics for the inspection. It includes liasing with the owners of the stores to arrange a time for the inspection (unless it is to be an unannounced inspection), planning the travel, and procuring the equipment. Some basic information is required in the planning and preparation of site inspection. The team should establish the following: Name of the Owner Geographical locations and address Names of person responsible for the store and the storekeeper Contact details - telephone numbers, addresses, email etc Indication of the size of the store Indication of the contents Normally it will be important to contact the owner in advance to obtain their permission to undertake the inspection. In circumstance where the team is concerned that illegal stocks might be held and that the owner might attempt to hide or remove them, the team should consider organising an unannounced inspection. In this case the team will require official government authority to undertake such an inspection. The review of the stores will assist the Sector Team determine the number of individuals required to carry out the inspection of the stores, and to allocate individuals to inspection teams, and nominate a leader for each team. 1 Instruction for Use of Inventory Forms Procurement of the tools and equipment necessary for the inventory is a critical process. It needs to be planned and managed effectively. Procurement rules for intentional organisations can be complex and require significant time to complete. Likewise the delivery times for some equipment can be lengthy. It is important that the procurement process commences promptly at the outset of the project to ensure that delays through lack of equipment are avoided. The following are some of the equipment that the inspection teams will require: Vehicles mobile telephone and charger - in remote locations satellite telephone systems or radios may be required personal protective clothing (sufficient to allow replacement of used items at the beginning of each day / inspection. Where the storekeepers are to assist in the inspections, sufficient PPE should be proved for them too. GPS tools. GPS co-ordinates should be measured and recorded in degrees, minutes and seconds together with the point of the compass. The seconds should be recorded to one decimal place (0.1 second = 3 metres). Before the inventory commences the GPS equipment should be pre-set to degrees, minutes and seconds and not to decimal degrees or degrees and decimal minutes. digital cameras with spare batteries, battery charger and additional flash-memory card and mechanism to download and store the digital images. It is important to protect the cameras from contamination while used in the stores. There are a number of options including: re-sealable plastic bags into which the camera can be placed plastic housings designed to allow the camera to be used under water These two options allow the camera to be washed after use in the store. mobile decontamination / washing facilities to clean PPE following inspections Paper forms for completing the inventory (store forms, risk analysis and material forms) sample forms, sample containers with labels and indelible pen cold storage for samples spill kits a safe repository for the completed forms during the travel between the stores Before embarking on the inventory, the teams should attempt to gather some basic information that can be used in the event of an emergency. For each site to be inspected the teams should attempt to find out the location and contact details of the nearest doctor/clinic, ambulance service, fire service, and police. This information can be refined during the site inspection. The information will also be useful during any subsequent safeguarding and disposal activities. The most efficient / cost effective itinerary should be planned for the inspection teams to visit all the stores. Unless the inspections are planned to be unannounced, they should liaise with the owners of the stores to ensure that the storekeeper will be present to assist in the survey. 3 Definitions The inventory forms use the terms "Site" and "Store". It is important that the differences between these two terms are clearly understood. 3.1 Site A site is a geographic location that can contain a single store or group of stores. A site could contain other buildings and have security arrangements such as fencing and gates. The following are examples of sites: 2 Instruction for Use of Inventory Forms 3.2 A compound with administrative buildings and one or a number of stores, both fenced and unfenced A single store with or without fencing. Store A store is a single stock of pesticides. Most commonly it is a single building containing pesticide materials. However it also includes stockpiles of drums of pesticides that are stored outside. 3.3 Site information and Store information Information to be gathered during the inventory will either relate to the site or the store. The information that relates to the site will be common to all the stores at the site, e.g. the logistics information about road access, and the services available at the site. The information about each store on the site will be specific to that particular store e.g. the condition of the building, and its contents. 4 The Forms The forms are made up of the following components: 4.1 Combined Site, Store and Risk analysis questionnaire This form is formatted as an A3 sheet, which is folded to make a 4 page A4 booklet. Page 1 captures information about the site Page 2 captures logistics information and the site plan Page 3 captures information about the pesticide store and the store plan Page 4 contains the Risk Analysis questionnaire In cases where there is a single pesticide store at the site, this combined form will be sufficient to gather all the necessary information for both the site and the store. ge Back Page Risk Analysis Questionnair e Page 4 Front Page Site Information Inside Left Pa Inside Right Pa Logistics, Site Plan and Site Photos Store Inform ation, Store plan an d Store Photos Page 2 Page 1 ge Page 3 Inside pages of booklet of combined Site / Store Form Outside pages of booklet of combined Site / Store Form 3 Instruction for Use of Inventory Forms 4.2 Supplementary Store and Risk Analysis Questionnaires Where a site has more than one store, it is necessary to complete a store plan and risk analysis questionnaire for each store. Pages 3 and 4 of the combined form described in section 4.1 above should be used to capture the store and risk analysis information for the first store. A separate supplementary A4 sheet (in the same format as pages 3 and 4 of the combined form with the store plan and risk analysis) should be completed for each additional store. 4.3 Material Forms Material forms have been designed to capture relevant information about the pesticides and other materials that could be found within each store. Forms have been designed for each of the following types of material: Pesticide products Veterinary products Empty contaminated containers Contaminated soil Contaminated other materials (e.g. seeds and fertilizer etc) Contaminated equipment (e.g. sprayers) Contaminated building materials 5 Site inspection and completion of forms The order in which the forms should be completed has been determined with the following objectives in mind: To meet with the key responsible person at the beginning of the inspection and before undertaking any other activity, to gather all the information that requires their input. This minimises the chance that the responsible person leaves the site before all relevant questions have been asked; Minimise the number of times it is necessary to change into and out of PPE. This saves time and minimises wastage of PPE that can only be worn once. If the inventory team is large enough, it is sensible to split it into it in two, Team1 - to undertake the activities that do not require PPE Team 2 - to undertake the activities that do require PPE 4 Instruction for Use of Inventory Forms Activities Team 1 (without PPE) Team 2 (requires PPE) 1. Meet with the responsible person 1. Assess the risks of the stores and 2. Complete the site information on choose the appropriate PPE page 1 and 2 of the Combined 2. Enter the first store Site, Store Form 3. Measure and draw a plan of the 3. Complete risk analysis questions interior of the store 1 to 6 on the combined form for 4. Take photographs of the interior of the the first store at the site (where store there is more than one store on 5. Undertake the inventory of the the site, for each other store, contents of the store complete a supplementary store 6. Answer questions 7 to 9 of the risk form and answer risk analysis questionnaires questions 1-6) 7. (where there is more than one store at 4. Tour the site with the responsible the site, repeat the activities for each person store) 5. Draw the plan of the site 6. Take photographs of the site 7. Measure and draw a plan of the exterior of the first store 8. Take photos of the exterior of the first store 9. (where there is more than one store at the site, repeat the exterior store plan and photos) When both teams have finished their respective activities, they should combine their findings onto the appropriate forms Where the inventory team is too small to divide up, a single team has to undertake all the activities. In this case it is important that the activities are undertaken in an order that elicits all the information from the responsible person at the beginning of the visit and keeps all the activities that require PPE together. The flow-chart in Figure 1 below shows the process steps for a single team to complete the forms. 5 Instruction for Use of Inventory Forms Work-Flow for Inventory forms Conclude meeting with the Responsible Person, agreeing the arrangements for the briefing at the end of the inventory Complete the Site Plan and photos of site Qs 1-6 of Risk Analysis Questionnaire for first store on page 4 of Booklet Meet with Responsible Person complete page 1 of Booklet with Site Information Journey to site make note of logistics information for access road to site Start Complete logistics Questions on Page 2 and tour the site with the Responsible Person. No Go to page 3 Complete the external details of the Store Plan, GPS info and external photos of store Is there another store at this site? Is there another store at this site? Yes Complete Supplementary Store Form with name of store and Qs 1-6 of Risk Analysis Yes Complete Supplementary Store Form with the external details of the Store Plan, GPS info and external photos of store No Complete Supplementary Store Form with the internal details of the Store Plan and internal photos and Qs 7-9 of Risk Analysis Put on PPE Exit store, leaving contaminated boot coveralls in store and go to next store, put on clean boot coveralls before entering Yes Complete Material forms for the contents of the store, take samples of unknowns Complete the store plan with the internal details and internal photos and Qs 7-9 of Risk Analysis Is there another store at this site? No Retain forms, photo files and samples according to protocols, pass them to Data Entry office for processing Brief Responsible Person of the findings, fill in the gaps and thank them for assistance Check for gaps in the information Exit store, leave all contaminated single-use PPE in the store, wash reusable PPE and cameras Stop Figure 1 - Process for Completing Inventory Forms Each process step is described in detail in sections 5.1 to 5.10. 5.1 On journey to site The journey to the site is a useful opportunity to observe the condition of the road and its hazards. This will be key information in planning the logistics of subsequent activities. The key things to identify and record are: For access road between the main road system and the site: the road surfaces and their length time required to reach the site any width restrictions the height restrictions of any low bridges, power lines or other structures that limit the height of vehicles that could access the site the weight limits of any bridges fords across rivers areas prone to landslides and other risks 6 Instruction for Use of Inventory Forms These points should not be recorded directly on the forms but used during the discussions with the responsible personnel at the site. 5.2 Arrive at site and meet key personnel The inventory will potentially take a long time to complete so it is important to meet with the key personnel such as the owner or their representatives immediately on arrival. The purpose of the meeting is to brief them of the activities that the inventory team will be undertaking; to ask for their full co-operation and that of their staff at the site; and to ask all the pertinent questions that require their input. It is important to obtain the answers from them at this stage, as they could well have to leave the site before the inventory is completed. It is time consuming and costly to have to follow-up unanswered questions at a later date. It is also good practice to meet the responsible person at the end of the inventory to brief them about the findings of the inventory and to ask any questions that have arisen during the inventory. 5.3 Start completing the Store Forms with the site information during the meeting with the responsible person Commence completion of page 1 of the A3 Booklet with “Site Information” Determine the site name. The site name is a name that refers to the location of the site the name should be unique in the country, if the name is likely to be duplicated in other parts of the country, try to use names of the local towns, districts etc that are distinct. This should be entered into the top of the form Determine the number of separate pesticide stores at the site. Also put this number at the top of page 1 of the form. Complete the top of page 3 for the first store by entering both the site name and the store name. If there is more than one store, initiate a supplementary store form for each additional store with the site name and its store name. Where the owners use names for each store, the forms should use these names. In the case, where the owners have not named the stores, the team may choose an appropriate name that may relate to the characteristics of the store. Alternatively the team could name each store using an alphabetical suffix, as in "store A", "store B" and "store C". The important consideration for the naming convention is that the combination of site name and store name must be unique as the combination will be used in the database as the identifier for the store. The database will not allow stores with identical site and store names. Continue completing page 1 with information about the Services at the site, such as electricity supply, lighting, water supply, washing facilities etc Contact information emergency services, - the information that the inventory team established about the local emergency services in advance of the visit should be checked with the responsible person to confirm that they are the most proximate to the site and confirm their capabilities. Following completion of page 1, move to the Risk analysis Page 4 and ask the questions in sections 1 to 6 of the Risk analysis questionnaire. The supplementary page should be completed for each additional store at the site - questions 1 to 6 answered for each store the conditions could be different. For each supplementary page make sure the correct site name and store name are written on top of page 3 before completing the questionnaire. Return to Page 2 and ask the logistics questions. The team should verify the observations that they made on the journey to the site with regard to the access road. 7 Instruction for Use of Inventory Forms Tour the site with the responsible personnel to identify the location of the stores and any contaminated soil. Obtain the information for the site plan. At this point the responsible person should have imparted all the necessary information. The remainder of the forms can be completed by the inventory team plus the storekeeper. 5.4 Site plan Draw the site plan on page 2. Only one plan should be required for the site. Mark the following on the plan: 5.5 the layout of stores, identifying each with its store name or alphabetical suffix layout of other buildings (especially those that can be used for storage of equipment and loading facilities) locations of soil contamination where drums of pesticides are stored outside each separate pile should be marked on the plan. Each pile should be considered a separate store. location of fences and gates directions and distances to nearest human settlements, wells, rivers and noting the gradient between the site and water source (uphill or downhill) take photos of the site and mark the direction in which they were taken on the plan mark the direction of north mark the scale of the plan Store information and plan The team should go to the store identified on page 3 of the A3 form and check that the site and store name have been entered correctly at the top of the page. The team should gather and record information about the store, in particular: The external dimensions The dimensions of its door Its GPS co-ordinates. GPS co-ordinates should be measured and recorded in degrees, minutes and seconds together with the point of the compass. Latitude is either N (north) or S (south) of the equator and Longitude is E (east) or W (west) of the Greenwich Meridian. The seconds should be recorded to one decimal place (0.1 second = 3 metres). Before the inventory commences the GPS equipment should be pre-set to degrees, minutes and seconds and not to decimal degrees or degrees and decimal minutes. In the grid on page 3, make a scale drawing of the external features of the store (DO NOT ENTER THE STORE AT THIS STAGE) mark the location of windows and doors mark the condition of walls - if the walls are full height /half height/ Dutch barn etc mark any external staining on the walls as evidence of leakage mark condition of the roof mark the direction of north take exterior photos of the store (door, walls, roof, staining, windows etc) mark the scale of the plan mark down the file names of the photos and their description in the form. Mark the direction of the photos on the plan The external details of each store should be recorded on its store plan before entering any of the stores. The plan of first store should be entered onto page 3 of the combined form, while that for the others should be drawn on their supplementary sheets. For each store at the site follow the same procedures as outlined in this section 5.5 8 Instruction for Use of Inventory Forms Complete external plans and external photos for all stores at the site before putting on protective clothing and entering any of the stores 5.6 Internal store plan A team of a minimum of two people should enter the first store - one from the inventory team and the store-keeper. The inspection team leader should make a risk assessment of the work to be done in the store. From the meeting with the responsible person, there should be an understanding of the likely content of the store. From this it may be possible to identify the risks and select the appropriate level of protection. Where there is no information, the level of protection should be for the most hazardous pesticide. Where the storekeeper is to assist the inventory team in the store, it is important that their level of training is assessed and that they are fully briefed of their responsibilities and the use of the protective clothing. At this point the team puts on the PPE and enters the store. They should take with them the appropriate equipment and forms for undertaking the inventory. In the store the team should: 5.7 Complete the store plan with the internal walls and doors Add the internal measurements Mark the locations of the materials in the store - including other items that are not pesticides Mark features that were not obvious from the exterior inspection Take photos of the general conditions inside the store and mark them on the plan, and fill in the fields at the bottom of page 3 Inventory of the materials in the store The system has been developed to cater for 7 material types Pesticide products Veterinary products Empty contaminated containers Contaminated soil Contaminated other materials (e.g. seeds and fertilizer etc) Contaminated equipment (e.g. sprayers and tools) Contaminated building materials Each material type has a standard form that is designed to capture appropriate information about its characteristics. The forms commence with identification of the site and store name (with its suffix) so that the material can be associated with the building or stockpile in which it was found. Each form continues with information about the pesticides or contaminant of the material. With pesticides this can be obtained from the label. With the other material types, the storekeeper may know the material that has caused the contamination. The forms continue with observations by the inventory teams on the condition of the material and its containers, and its quantity The forms finish with the file numbers of photographs of the labels, containers, condition of the material. 9 Instruction for Use of Inventory Forms The layout of each material form is in a similar style. Each question is numbered, and has a clear description of the information required. The questions are in the same order and have the same number in each form. Where possible tick boxes have been used to minimise the amount of writing required. The tick boxes relate to options that are specific to the type of material. Where a particular question is not relevant to a type of material, that question has been omitted from the material form. In order to maintain the commonality of question numbers between the forms, the omitted question's number is also omitted. There is a tick box on the right hand side of each question. Where the team wish to add a comment about a particular question, this box should be ticked and the comment noted on the reverse of the form, together with the number of the question to which the comment relates. A line should be drawn under each comment to separate it from the next comment. 5.7.1 Grouping items for entry on a single material form For each distinct and unique pesticide a separate form should be completed. A distinct and unique pesticide will have the following same characteristics Same material Same commercial name, formulation, manufacturer, Same package size, Same batch and manufacture date (if shown on label) Same condition of containers Same condition of product Same % full for each package The inventory team should move around the store together with the storekeeper identifying the materials that can be grouped as unique and distinct. The storekeeper should count the containers and identify how full each item is. The inventory team member should record the details on the appropriate form and check that the counting is correct. Photos of the label, containers and contamination should be taken with the file numbers and descriptions recorded on the form. Additional photos should be taken in cases where the material has features or peculiarities that should be recorded to assist in identification or in planning the safeguarding and disposal steps. 8. The instructions for how to complete each question are shown in section 10 Instruction for Use of Inventory Forms 5.7.2 Completing the material forms The table below describes each of the questions that appear in the 7 material forms, and provides guidance on how they should be answered. No Question . 1 Store Name Applicable to Material types All 2 Owner (if different from owner of store) How to complete The name of the site and store (including any suffices) so that the material form can be matched up with its corresponding store form If the owner of the material is different from the owner of the store, e.g. in the case where pesticides and sprayers belonging to a number of organisations are held within a strategic store, the name and address of the owner should be entered Pesticide, Veterinary Product, Empty drums Equipment Questions 3 to 16 relate to information about the pesticide or pesticide contaminant. For a pesticide product, veterinary product or empty container the information should be obtainable from the label of its container; For contaminated materials, equipment, building materials, and soil it may be possible to identify the likely cause of the contamination and therefore the name of the contaminant. For example, if soil has become contaminated because drums have leaked into it, the information about the contaminant can be obtained from the labels on the drums. Similarly for sprayers, the storekeeper may be able to confirm the name of the pesticides that were used in the sprayers. With contaminated materials it is possible that no information is available about the pesticide contaminant, in which case it is generally recommended that a sample of the collected for analysis later. 3 Labels on Containers Pesticide, Veterinary The presence of labels on the containers should be indicated by selecting "yes" or Product, Empty drums "no". 4 Readable labels Pesticide, The condition of the label in relation to its legibility should be confirmed by selecting Veterinary Product, "yes" or "no". The label may be in a language that the inventory takers are unable to Empty drums read. In this case the labels are "readable", but a comment should be made that the label will require translation 5 Commercial Name All The commercial or trade name of the pesticide product or contaminant 6 Active Ingredient name All The name of the active ingredient in the pesticide if it is identified on the label or is known by the storekeeper should be entered here. Where there is more than one active ingredient, all of them should be entered. If the Active ingredient is unknown, the "unknown" tick box should be selected and where appropriate a sample should be taken. The number of the sample jar should be noted 11 Instruction for Use of Inventory Forms No Question . 7 AI Concentration Applicable to Material types Pesticide, Veterinary Product, Empty drums 8 Manufacturer's name and address All 9 Formulator's name and address All 10 Batch number Pesticide, Veterinary Product 11 Date of Manufacture Pesticide, Veterinary Product 12 Expiry Date Pesticide, Veterinary Product How to complete The concentration of the Active Ingredient should be entered as a percentage. They should also tick the appropriate box to confirm the nature of the percentage - volume / volume, weight / weight, or weight / volume. If the inventory team is in doubt about converting the concentration into a percentage, they should just enter the concentration and units (e.g. mg/l or mg/kg) as they appear on the label. If there are more than one active ingredient each of the concentrations should be recorded (in the same order as in Box 6) If the concentration is not shown on the label, the "unknown" box should be ticked. If the concentration in box 7 is "unknown" it may be necessary to collect a sample. If the active ingredient is unknown, a sample is always required. If the active ingredient is known and the total quantity exceeds 1 tonne, a sample is required to be taken. In all other circumstances it is not necessary to take a sample. Where a sample is take, the sample number on the sample jar should be recorded on the form. The manufacturer's name and address should be written in box 8. Where the name is not shown on the label or there is no label and the storekeeper cannot provide the name, the team should write "unknown". The formulator's name and address should be written in box 9. Where the name is not shown on the label or there is no label and the storekeeper cannot provide the name, the team should write "unknown". The label will normally show the manufacturer's or formulator's batch number for the production of the product. This number should be entered into box 10. Where there is no batch number on the label, the box "not shown on label" should be ticked. The label will normally show the manufacturer's or formulator's date of production of the product. This date should be entered into box 11. Where there is no indication of the date of manufacture on the label, the box "not shown on label" should be ticked. The label may show the manufacturer's or formulator's expiry date or the"use by" date of the product. This date should be entered into box 12. Where there is no indication of the expiry date on the label, the box "not shown on label" should be ticked. 12 Instruction for Use of Inventory Forms No Question . 13 UN Chemical Hazards Classification (warning diamonds on the containers) Applicable to Material types All How to complete Where the hazards of the pesticides or pesticides contaminants are known, they should be entered in box 13. Pesticide containers that have been imported are likely to have one or more of the UN labels that are shown as pictograms in box 13. In this case the labels in box 13 can be used to indicate the hazards. The primary hazard should be indicated by writing "1" in the box by the appropriate label. The secondary hazard should be indicated by writing a "2" in the box by the appropriate label. It is possible that the containers will carry a different type of label, such as the EU product hazard labels. In this case, the hazards should be indicated as a comment on the reverse of the form. 14 How supplied / Name of Supplier 15 Formulation Type All Where there are no labels to indicate the hazard of the pesticide or contaminant then, the “not shown on label” or “unknown” box should be ticked. The tick box should be used to indicate how the pesticide or the pesticide contaminant (in the case of soil etc) was supplied. If the name of the supplier / donor is known, it should be written into the space provided. For contaminated materials it is likely that the supplier will be unknown. Only where it is possible to link specific pesticide drums of known provenance to contaminated materials, will it be possible to fill in this box. The tick box should be used to indicate the formulation type. If the Pesticide, Veterinary Product 16 Name of the Solvent Pesticide, For liquid pesticides, where the label specifies the solvent, its name should be Veterinary Product indicated in Box 16 Questions 17 to 27 – Observations and Quantities The information to be entered in these boxes should be obtained by make observations about the physical properties of the pesticides or contaminated materials. 13 Instruction for Use of Inventory Forms No Question . 17 Condition of product 18 Level of contamination 19 Physical form (Type of Soil) 20 Container type 21 Container material Applicable to Material types Pesticide, Veterinary Product Building Materials Empty Containers Equipment Materials Soils Building Materials Equipment Materials Pesticide, Soils Veterinary Product Empty Containers Materials Pesticide, Soils Veterinary Product Empty Containers Materials Pesticide, Soils Veterinary Product How to complete From an inspection of the pesticide or veterinary product the inventory team should assess whether the product appears to be usable or not. The team should not concern themselves with the expiry date of the material; they should just consider its physical appearance and whether it is likely to be usable. They should indicate their assessment using the appropriate tick box During the inventory there is no need to take samples specifically for usability testing. Once the inventory results have been analysed in OPMS, a decision will be made whether it is worthwhile to analyse for usability. The tick box should be used to indicate the level of contamination of the material. The level is determined from the appearance, for example if stains from the contamination are visible or the contamination can be smelled. The tick box should be used to indicate the physical form of the material. The tick box options vary depending on the type of material The tick box should be used to indicate the type of container (if any) in which the material is contained. The tick box options vary depending on the type of material If the material is not held within a container “none” should be selected. In this case there is no need to answer questions 21, 22 and 23 that relate to specifics of the container. The tick box should be used to indicate the type of material from which the container is constructed. 14 Instruction for Use of Inventory Forms No Question . 22 Have containers been opened 23 Container size 24 Unit of Measure of the Container size Applicable to Material types Materials Pesticide, Veterinary Product Empty Containers Equipment Materials Pesticide, Soils Veterinary Product All 25 Amount in container Materials Pesticide, Soils Veterinary Product 26 Container Condition Empty Containers Materials Pesticide, Soils Veterinary Product How to complete Whether the containers have been opened at some stage during their history (i.e. the contents could have changed from original sent by the manufacture) should be indicated by selecting "yes" or "no". The inventory team should assess the size of the container using boxes 23 and 24. Box 23 should be used to record the number of units of measure and box 24 to record the units of measure. For example if the pesticides are packed in 50 litre drums, “50” should be written in box 23 and the tick box for “litre” should be ticked in Box 24 see box 23 above The tick box should be used to indicate how full the containers are. The options are: 100%, 75%, 50%, 25% or 0%. Where there are two lots of the same pesticide in the same size drums which are all identical except that the amounts in the container are different, rather than having to write a completely new form for each lot, the comments box on the reverse can be used to document the amounts in the containers. For example: 4 drums 100% full 16 drums 75% full and 2 drums 25% full The tick box should be used to indicate the condition of the containers (whether they are damaged or not) 15 Instruction for Use of Inventory Forms No Question . 27 Quantity (only complete one of 27a or 27b) Applicable to Material types All How to complete This is one of the most important boxes. Because the condition that inventory teams find within stores varies considerably, the forms have been designed to allow the teams 2 ways of determining the quantity on a form. for items that are readily countable: Box 27a should be used to record the number of items. For example, if boxes 20 to 26 have been completed and the containers are not “completely destroyed with contents dispersed” the containers can be counted. In this case the inventory team should just enter the number of containers that they have counted in box 27a. There is no need to do any calculations. When the information for the form is entered into OPMS the application will calculate the total quantity based on everything that has been entered in boxes 23 to 25. for items that cannot be counted: Box 27 b should be used in the following cases: containers that are completely broken and contents dispersed the materials are not in containers and cannot be counted the materials such as soils are either still in situ in the ground or have been excavated into piles In these cases the dimensions of the quantity of material should be estimated in terms of its length, width and height (all in metres). These dimension will be used by the OPMS application to calculate the volume of the material, and when multiplied by its density, the total quantity as a weight. When the material is not in a rectangular shape, but in a conical pile or an amorphous shape in-situ in the ground, it is important that the inventory teams record the average for each dimension and not just its maxima. By recording the average length of each dimension OPMS will calculate a realistic estimate of the volume. Where maximum dimensions are recorded the calculated quantity will be significantly over estimated. 16 Instruction for Use of Inventory Forms No . Question Photos Applicable to Material types all How to complete The forms indicate the type of photos required to be taken of the product or material. In most cases the forms recommend 3 photos (for example in the case of pesticides it recommends one of the label, one of the containers and another of the contamination e.g. if the containers are leaking). It is important that photos of any labels are taken and are checked for clarity. The label photo may well be needed as evidence for discussions with manufacturers, formulators and donors. The inventory team may take as many photos as they deem necessary to adequately document the material, and its contamination. Samples building materials pesticides, soils veterinary products For each photograph the team should record on the form its file number (e.g. img2389.jpg) and a description of the scene in the photo. The inventory team should record the identification numbers of the sample jars and a description of the sample, where it was taken and other pertinent facts. For example with soil samples it is important to record the location that the sample was extracted, whether it was a core sample or the depth at which the sample was taken. 17 Instruction for Use of Inventory Forms 5.7.3 Sampling As far as possible the inventory team should take samples of everything that is likely to require analysis in relation to the follow-on steps of safeguarding and disposal. It is costly and time consuming to have to return to the site to take samples, so if the team is in doubt, it should take samples. The following Samples are required in the following circumstances: 5.7.3.1 Pesticides and Veterinary Products Samples are required when: 1. the active ingredient cannot be identified from the label or from investigations of similar containers within the store, or 2. the concentration of the active ingredient cannot be found from the label or other store documentation AND the quantity of the material exceeds 1 tonne 5.7.3.2 Soil Samples are required to be taken at the time of the inventory in cases where contaminated soil has been identified. Core samples should be taken from hotspots in the contaminated area. 5.7.3.3 Other materials In the case of other contaminated materials - empty drums, equipment, materials (fertilizers, seeds etc), and building materials – generally samples will not be necessary, but when they are required, they can difficult to obtain. The inventory forms do not specifically prompt for samples to be taken. It is left to the discretion of the inventory teams to take samples where they deem it necessary. Samples should be taken in cases where there is gross contamination and the contaminant will have to be identified before the safeguarding and disposal stages. 5.7.3.4 Sampling protocols and methods As part of the inventory guidance, sampling protocols and methodologies will be provided to the inventory teams. Training modules on sampling will also be developed 5.7.3.5 Sampling pesticides for usability Samples should not be collected for products that appear to be usable. During the review of the inventory data in OPMS by the Validator, an assessment will be made on the demand and availability of usable pesticides. If materials have to be tested for usability, the site will be revisited to obtain the samples. 5.7.3.6 Administration and handling samples The samples should be placed in numbered glass jars. The sample numbers should be recorded on their respective material forms, so the analysis may be referenced to the appropriate material. Separate procedures are being developed for sampling and analysis of unknown materials. The samples should be stored in conditions that they remain representative. 5.8 Completion of a store's inventory When all the materials within a store have been inventoried onto the material forms, the forms should be stapled to the appropriate store form (page 3). The remaining risk analysis questions 7 to 9 should be completed on page 4. 18 Instruction for Use of Inventory Forms 5.9 Other pesticide stores at the site If there is more than one store on the site, the team should exit the store leaving their contaminated boot covers in the completed store. This avoids contaminating the areas around the store. They should continue to wear the other PPE, and proceed to the next store, put on new boot covers, enter the store and complete its store plan (interior) and inventory. They should follow the same procedures as set out in sections 5.6 to 5.8. When they exit the last store, they should clean all reusable PPE and the cameras. They should remove all disposable PPE and leave it in the store. 5.10 Wrap-up The forms should be checked for completeness. Where there are gaps the team should attempt to resolve the missing information by contacting the responsible person. The inventory team should check that they have not missed any stores by checking that they have the same number of completed store forms as there were stores identified at the top of page 1 of the combined form. They should meet with the responsible person to brief them of their findings and thank them for their assistance. 6 Retention and transport of the completed forms and samples The forms should be put inside the A3 combined form and sealed within a plastic wallet. The information contained in the forms is valuable so they should be protected from damage (e.g. water, fire etc) and stored in a secure place. It is also important that forms from various stores and sites do not get mixed up. The booklet format should minimise the likelihood of this eventuality, as all forms for a site can be kept inside the booklet for the site. Stapling the material forms to their respective store form keeps them associated to the correct store. The compact flash card from the digital camera should be sealed in an envelope with the site name written on the outside. The envelope should be placed in the sealed plastic wallet along with the inventory forms. The plastic wallet should be labelled with the name of the site. Samples should be stored according to the protocol (under development) to ensure that they remain representative of the materials from which they were taken. 7 Data Entry The forms and samples should be passed to the office for data entry and for the sample analytical procedures. The procedures for data entry into OPMS will be detailed in specific documentation for the application. 19