05_SWP_Cell Cycle Analysis with Flow Cytometry_JC

advertisement

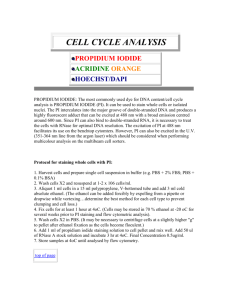

OHS026 Safe Work Procedure Faculty/Division Medicine Document number SOMS.CGM.SWP005 School/ Divisional Unit School of Medical Sciences ORU/MDU Initial Issue date 26-6-09 Current version 1 Current Version Issue date 26-6-09 Next review date 26-6-09 The Writing Safe Work Procedures Guideline (OHS027) should be consulted to assist in the completion of this form. Safe Work Procedure Title and basic description Title: Cell Cycle analysis with flow cytometry Description: To determine cell number and DNA content using flow cytometry Associated risk assessment title and location: 05_RA_Cell Cycle analysis with flow cytometry_JC Describe the activity or process Harvest all the adherent and floating cells in the dish or flask. This means transferring into a centrifuge tube, the medium that the cells have been growing in and the pre-trypsin wash, as well as the trypsinised cells themselves. Centrifuge at 300 rcf for 5 minutes. Resuspend the cells in 10mls of warm PBS, then take out an aliquot to count while you centrifuge again at 1500rpm for 5mins. Resuspend the cells in cold PBS at a concentration of 106/ml. Transfer 250ul of cells (i.e. 2.5x105 cells) to a 1.5ml eppendorf tube. Add an equal volume (250ul) of ice-cold 70% ethanol and mix by inversion several times. Incubate tube on ice for at least one hour. At this stage the cells can be left for up to ten days at 4oC. Centrifuge the cells at 4oC at 1500rpm for 5 mins. Discard the supernatant and add the following mix to the cells : 5ul Propidium Iodide (1mg/ml stock, made up in water) 2ul RNase (0.5mg/ml) 475ul PBS (warm) Mix gently by inversion. Incubate tube in dark (PI is light-sensitive) at 37oC for 30 mins. Transfer sample to FACS tube and run on flow cytometer at low speed (< 200 cells/sec). Specific protocols associated with each flow cytometer (refer to flow cytometry facility). List all resources required including plant, chemicals, personal protective clothing and equipment, etc Propidium iodide Flow Cytometer Trypsin Centrifuge Ethanol (70%) PBS RNase FACS tubes Eppendorf tube ___________________________________________________________________________________________________________ ___________ Page 1 of 2 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007 List potential hazards and risk controls including specific precautions required 1) Toxic chemical risk - Propidium Iodide - Low Risk. Mild irritants, potential mutagen. Risk Controls: use of protective clothing (lab coat, gloves and safety glasses), use of disposable pipette tips 2) Electrical Hazard – Flow cytometer – Low Risk. Potential electrical hazard. Risk Controls: Equipment routinely tested and tagged. User is appropriately trained. 3) Fire Hazard – Ethanol – Low risk. Risk Controls – keep confined, no ignition sources nearby. List emergency shutdown instructions Shutdown button located at entrance to lab. Emergency contact Renee Szokolai ext 58497 List clean up and waste disposal requirements Dispose of material in biological waste bin. List legislation, standards and codes of practice used in the development of the SWP NSW OHS Act 2000 NSW OHS Regulation 2001 Code of Practice for the Labelling of Workplace Substances AS/NZS 2243.2:2006. Safety in laboratories. Part 2: Chemical aspects AS/NZS 2243.3: 2006 Safety in laboratories Part 3: Microbiological aspects and containment facilities AS/NZS 2243.6-1990. Safety in laboratories. Part 6: Mechanical Aspects. AS/NZS 2243.3:2006 Safety in Laboratories Part 7 Electrical aspects AS/NZS 2161.1:2000 Occupational Protective Gloves – Selection, Use and Maintenance Supervisory approval, training, and review Supervisor: Signature: Plant custodian: Signature List competency required – qualifications, certificates, licencing, training - eg course or instruction: Training as per training needs analysis, Induction to Lab, Training on this SWP ___________________________________________________________________________________________________________ ___________ Page 2 of 2 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007