Incident_Report_4-8

advertisement

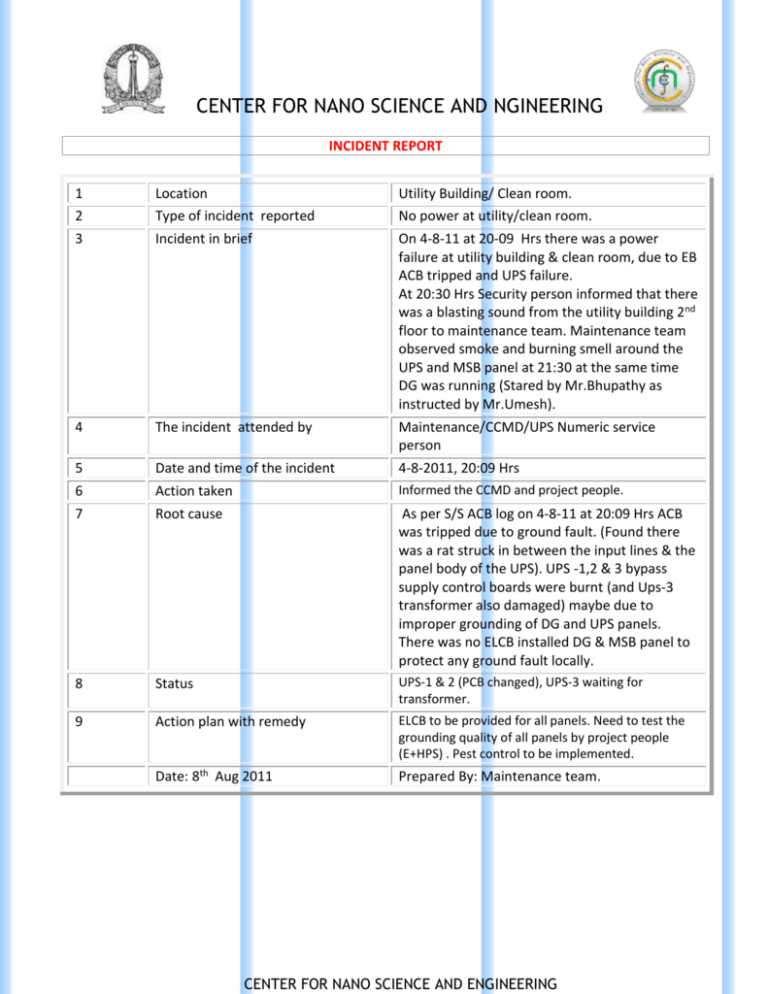

CENTER FOR NANO SCIENCE AND NGINEERING INCIDENT REPORT 1 Location Utility Building/ Clean room. 2 Type of incident reported No power at utility/clean room. 3 Incident in brief On 4-8-11 at 20-09 Hrs there was a power failure at utility building & clean room, due to EB ACB tripped and UPS failure. At 20:30 Hrs Security person informed that there was a blasting sound from the utility building 2nd floor to maintenance team. Maintenance team observed smoke and burning smell around the UPS and MSB panel at 21:30 at the same time DG was running (Stared by Mr.Bhupathy as instructed by Mr.Umesh). 4 The incident attended by Maintenance/CCMD/UPS Numeric service person 5 Date and time of the incident 4-8-2011, 20:09 Hrs 6 Action taken Informed the CCMD and project people. 7 Root cause As per S/S ACB log on 4-8-11 at 20:09 Hrs ACB was tripped due to ground fault. (Found there was a rat struck in between the input lines & the panel body of the UPS). UPS -1,2 & 3 bypass supply control boards were burnt (and Ups-3 transformer also damaged) maybe due to improper grounding of DG and UPS panels. There was no ELCB installed DG & MSB panel to protect any ground fault locally. 8 Status UPS-1 & 2 (PCB changed), UPS-3 waiting for transformer. 9 Action plan with remedy ELCB to be provided for all panels. Need to test the grounding quality of all panels by project people (E+HPS) . Pest control to be implemented. Date: 8th Aug 2011 Prepared By: Maintenance team. CENTER FOR NANO SCIENCE AND ENGINEERING CENTER FOR NANO SCIENCE AND NGINEERING S/S ACB tripped Rat struck in UPS UPS bypass supply control board burnt out. CENTER FOR NANO SCIENCE AND ENGINEERING CENTER FOR NANO SCIENCE AND NGINEERING Root Cause Analysis Tree Issue Root Cause Machines/Equipment Manpower Lubrication failure Lack of tech skills Setting failure Attitude problems Parts/Ass’y failure Lack of team spirit / ownership Insufficient capacity Lack of Eqpmt knowledge ✔ Power failure Fatigue, stress, sick Fuses blown Lack of communication/awareness Controls malfunction Design / Commissioning problem Methods Lack of relationship bldg Lack of org. objectives/goals Measurements Lack of policies & procedures Gauges/meter malfunction Lack of work instructions Calibration errors Lack of technical training Lack of history analysis tools Lack of soft skills training Measurement systems not in place Improper equipment layouts Lack of predictive knowledge Lack of quality concepts Insufficient measuring systems Lack of PM systems Lack of policies & procedures Material Parts premature failure Insufficient stock levels Poor quality materials Over aged materials Structural defects Environment Room/facility temperatures high/low High humidity conditions High dusty conditions Noise pollution Smoke or haze pollution Heavy rains/Tsunami/Typhoons Fire / volcano eruptions CENTER FOR NANO SCIENCE AND ENGINEERING