Two methods of determining the density of vulcanized rubber

advertisement

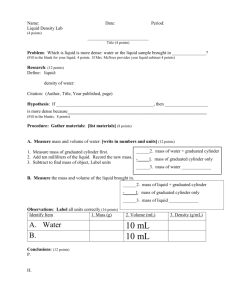

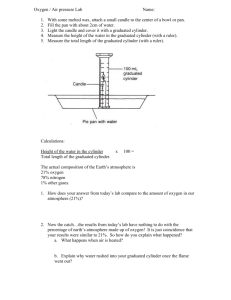

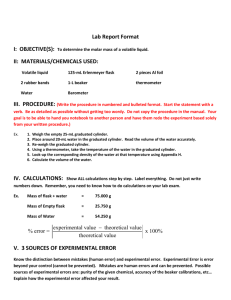

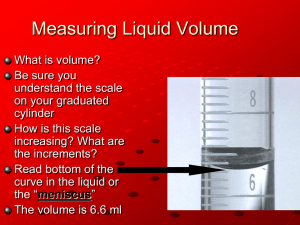

Two methods of determining the density of vulcanised rubber Objectives: In this practical you will determine the density of a rubber material by both: Directly measuring the diameter, height and mass of a cylindrical test piece and apply the density formula m V Indirectly using the Archimedes’ Principle. For this purpose you’ll become familiar in both using the vernier caliper and making accurate measurements with a graduated cylinder by avoiding parallax. You will also learn a rough method for calculating experimental uncertainties involved in your measurements. Some Definitions: “The definition of terms is the beginning of wisdom” - Socrates (469-399 B.C) Density is the mass per unit volume of a substance under specified conditions of pressure and temperature. Thus, density is a measure of how much mass is contained in a given unit volume (density = mass/volume or m ). The SI unit of density is the kilogram V per cubic meter (kg/m3). Put simply, if mass is a measure of how much ‘stuff’ there is in an object; density is a measure of how tightly that ‘stuff’ is packed together. Strictly speaking, there are two different quantities called mass: Inertial mass is a measure of an object's inertia: its resistance to changing its state of motion when a force is applied. An object with small inertial mass changes its motion more readily, and an object with large inertial mass does so less readily. Gravitational mass is a measure of the strength of an object's interaction with the gravitational field. Within the same gravitational field, an object with a smaller gravitational mass experiences a smaller force than an object with a larger gravitational mass. (This quantity is sometimes confused with weight, which is the force experienced by a mass. An object will have a larger weight if it is placed in a stronger gravitational field, but its gravitational mass remains unchanged.) 1 Archimedes’ Principle: “a body fully or partially immersed in a fluid is buoyed up by a force equal to the weight of the fluid that body displaces.” There is an interesting legend that accompanies this principle. Apparently Archimedes was asked by his close friend/relative King Hiero II whether a wreath (often falsely stated to be a crown) he received was pure gold or alloyed with another metal like silver as he suspected. He could not destroy the wreath to make the determination. Archimedes didn’t come up with a solution until one day while considering the question, "the wise one" entered his bathtub and recognized that the amount of water that overflowed the tub was proportional the amount of his body that was submerged. He suddenly realized that since gold is more dense than silver, a given weight of gold will have less volume than an equal weight of silver. Consequently, the gold would displace less water than an equal in weight sample of silver. He was so excited that he ran naked through the streets of Syracuse shouting "Eureka! eureka!" (I have found it!). Upon conducting the experiment, he found that a sample of gold equal to the weight of the wreath displaced significantly less water than the wreath. This insight led to Archimedes Principle. Parallax Error: Error that can be introduced when not reading an instrument directly from its front, due to the separation of the indicator and the scale being read. (See figure below): Fig. 1. The parallax error in measurements 2 Direct Method Experimental Procedures Weight the rubber test piece to the nearest mg using one of the analytical balances provided. Make sure that the balance reads zero before you begin your measurement (i.e.: you can zeroed any digital balance by pressing the “tare” button). Place the test piece at the centre of the balance weighting pad and close balance’s doors (if applicable). Wait for a while until the reading stabilises and carefully record the reading. (DO NOT FORGET UNITS). After your weighting check if the balance reads zero. If this is not the case, reset the balance to zero by pressing the “tare” button. Use the vernier caliper provided to measure the diameter of the cylindrical test piece. As the test piece may not be a perfect cylinder, you need to measure its diameter at three different places to the nearest 0.1mm (see figure 2). Make sure that what you are measuring is indeed the diameter of the test piece. In other words, make sure that the jaws of the vernier caliper used are perpendicular to the length of the cylindrical test piece (as illustrated in the relevant movie). Record your readings without forgetting the relevant units. Finally, measure the height of the test piece in three different points to the nearest 0.1mm and record your readings. Fig. 2 Suggested points for measuring the diameter & height of the cylindrical sample 3 Expression of Results Record you results in the following table: Test piece Determination of Density (Method A) Mass Diameter Height (mm) (mm) (mg) 1 2 3 1 2 3 Volume (mm) 1 2 3 Average Density (mg/mm3) Average values In order to find the volume of the cylindrical test piece use the equation: V r2 h (1) Now the density can be calculated by the following formula: mV (2) What to do: 1. Express the measured density of the test piece in SI units (kg/m3). Show all calculations 2. Make a list of all the sources of uncertainties you can think of. Which of these is more important and why? 3. Choose the two values of the volumes that maximise and minimise the density of the test piece respectively. After finding the maximum and minimum densities express your final result as follows: min Result max 2 Don’t forget the relevant units. As soon as you finish, proceed to the indirect Method 4 Indirect Method Experimental Procedure Weight the clean and dry graduated cylinder provided. Record your reading as m1. Insert the test piece into the dry graduated cylinder and weight it. Record your reading as m2. Fill the graduated cylinder, containing the rubber, with distilled water until the test piece is completely immersed. Using a burette or transfer pipette continue to slowly add distilled water until the bottom of the meniscus matches exactly an indication of your choice. (For a correct reading of the graduated cylinder consult figure 3). If you want to extract a small quantity of water you may use a small syringe. Record this reading as L. Dry the outside of the graduated cylinder carefully. Weight the bottle and contents and record your reading as m3. Empty the cylinder completely and refill it with distilled water until it reaches the mark L. Add or extract small quantities of distilled water as before. (It is very important that the bottom of the meniscus matches exactly the indication L when viewed from the proper line of sight). After a careful drying of the outside of the graduated cylinder, weight the cylinder and water. Record this reading as m4. Fig. 3 How to avoid parallax when reading a graduated cylinder. 5 Expression of Results Record your measurements in the following table: Test piece Determination of Density (Method B) m1 m2 m3 m4 (mg) (mg) (mg) (mg) Density : m2 m1 m4 m3 m2 m1 (Mg/m3) 1 2 3 1 Average Density (density max - density min) 2 What to do: 1. If there is enough time left repeat this experiment 1 to 2 more times in order to calculate an average value and obtain a rough estimate of its error for the density of the test piece. 2. Make a list of the sources of uncertainties involved with your measurements. Suggest improvements in the experimental procedure that can minimize these errors. 3. Convert the determined density in SI units. Compare this value to the relevant direct method’s result. Are both test pieces made from the same material? 6