Word - 50KB - Department of the Environment

advertisement

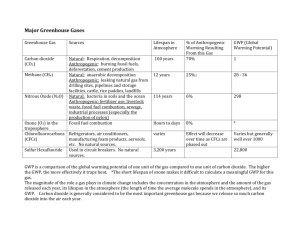

TRANSITIONING TO LOW GLOBAL WARMING POTENTIAL REFRIGERANTS One objective of the equivalent carbon price, which was introduced as part of the Clean Energy Future Plan on 1 July 2012, is to encourage a transition to gases, including refrigerants with low global warming potential (GWP). An equivalent carbon price applies to the import and manufacture of synthetic greenhouse gases in bulk forms and in equipment. The equivalent carbon price is applied under the existing Ozone Protection and Synthetic Greenhouse Gas Management Act 1989. Applying an equivalent carbon price to SGGs provides incentives for users to: increase recycling of synthetic greenhouse gases improve servicing of existing equipment to reduce leakage of refrigerant gases switch to purpose-designed equipment using lower GWP refrigerants, only where this is appropriate and meets relevant safety standards and legislative requirements use innovation to develop safe, low GWP refrigerants and suitably designed equipment for those refrigerants. Synthetic greenhouse gases are industrial chemicals used mainly as refrigerant gases in refrigeration and air-conditioning equipment. These gases generally have a high GWP, some in the range of 140 to 23 900 times that of carbon dioxide, and can exist in the atmosphere for more than 3000 years. For example, the most common refrigerant used in Australia, R134a, has a GWP 1300 times that of carbon dioxide. The equivalent carbon price applied to synthetic greenhouse gases is calculated by multiplying the carbon price ($23.00 a tonne in 2012–13) by the GWP of the synthetic greenhouse gas. This means the higher the GWP of a gas, the higher the equivalent carbon price will be. Along with the equivalent carbon price there is also an additional cost recovery levy1 applied to all synthetic greenhouse gases. Environmental and economic considerations provide a good incentive for users to transition to a low GWP gas. Low GWP Refrigerants Several refrigerants with very low GWP are available in Australia. These include natural refrigerants and Hydrofluoroolefins (HFOs). Natural refrigerants include ammonia, carbon dioxide and hydrocarbons2 and are generally referred to as ‘natural’ because they contain naturally occurring substances. Hydrofluoroolefin (HFO) is a low GWP liquid that is currently used overseas as a replacement for R134a. Natural refrigerants and HFOs do not have an equivalent carbon price. They can offer improved performance (when compared to synthetic greenhouse gases and other high GWP refrigerants) and energy efficiency in fit for purpose3 systems. Ammonia (GWP of zero) Ammonia (NH3, refrigerant designation R717) has been used in refrigeration systems since the 1800s and has been the refrigerant of choice in areas such as industrial refrigeration for many years. Ammonia is often used in the food industry and large cool stores due to its high energy efficiency. During the last two to three decades ammonia has also been used in smaller systems including low charge liquid chillers for air conditioning of commercial buildings. Carbon dioxide (GWP of one) Carbon dioxide (CO2) is a substance that has been used in the refrigeration industry since the 1860s. It is commonly used in industrial freezers, large cold storage applications, supermarket systems and domestic heat pumps. Carbon dioxide is now commonly being used in what are referred to as cascade or secondary loop systems. In these systems CO2 can be used as the primary or secondary refrigerant. Hydrocarbons (GWP of between three and 20) Hydrocarbon encompasses a range of substances. The hydrocarbons most commonly used as refrigerants are ethane (known as R170), propane (R290), butane (R600), isobutane (R600a) and propylene (R1270). Hydrocarbon refrigerants have been used widely in petrochemical industries, particularly very large refrigeration systems. As awareness and understanding of hydrocarbons grows, so too does the use of the gas: for domestic refrigeration, standalone and split system air conditioning, motor vehicle air conditioning (purpose built systems) and food retailing such as vending machines, display cabinets and chillers. 2 While the term hydrocarbons encompasses a number of different gases, each of these with a different chemical composition, they all share the same basic environmental properties. Hydrofluoroolefins (GWP of between three and six) Hydrofluoroolefins (HFOs) are low GWP fluids composed of hydrogen, fluorine and carbon. HFOs are produced for the use in a range of applications including mobile and stationary air conditioning, refrigeration, aerosol propellants and foam insulations. Internationally, the automotive industry has been considering the use of HFOs as the possible future replacement for R134a (currently being used in car air conditioners),4 with some vehicles in Europe and the United States already being manufactured using HFO-1234yf. Considerations Strict regulations, standards and procedures must be followed when handling refrigerants. These vary between states and territories and the relevant authorities should always be consulted to ensure legal requirements are followed. Safety It is important that refrigerants are only used in equipment that is fit for purpose. All refrigerants (including synthetic greenhouse gases and low GWP refrigerants) should be handled with care. Each refrigerant comes with its own unique risks, some have a high level of toxicity, some are flammable and some are used under high pressure. If substituted incorrectly, or used in unsuitable equipment without an appropriate risk assessment and consideration of relevant work health and safety procedures, all refrigerants can pose a safety hazard. Equipment manufacturers, gas suppliers, refrigeration engineers, technicians and state and territory work health safety regulators, can provide advice on equipment and refrigerants issues, warranties and safety. Licensing requirements for handling refrigerants Warning: Individuals who handle fluorocarbon refrigerants without a licence are committing an offence. 3 The Ozone Protection and Synthetic Greenhouse Gas Management Regulations 1995 do not require a refrigerant handling licence for handling natural refrigerants. However, any individual (including a repairer or dismantler) who removes fluorocarbon refrigerants such as halocarbons, chlorofluorocarbons (CFCs), hydrochlorofluorocarbons (HCFCs) and hydrofluorocarbons (HFCs) from any refrigeration or air-conditioning system, including for the purposes of substitution with a low GWP refrigerant, must hold at a minimum a Restricted Refrigerant Recoverer Licence. Licences can be obtained from the Australian Refrigeration Council at www.arctick.org. Complying with standards for prescribed electrical equipment5 Refrigeration and air-conditioning equipment must comply with relevant Electrical Safety Standards. Equipment intended for conversion to a substitute refrigerant (including low GWP refrigerants) must be re-certified as compliant to the relevant standard by the approval issuer. The approval issuer can be an electrical safety regulator or a third party certifier. More information For more information about the equivalent carbon price for synthetic greenhouse gases, including factsheets, licensing and an online price calculator, go to www.environment.gov.au/atmosphere/ozone/sgg/equivalentcarbonprice/index.html, email ozone@environment.gov.au or phone the department on 1800 803 772. For more information about the Clean Energy Future package, go to www.cleanenergyfuture.gov.au/ Fact sheet: Safety considerations relating to low GWP natural refrigerants www.environment.gov.au/atmosphere/ozone/sgg/equivalentcarbonprice/publications/pubs/fs14ecp-rac-safety.pdf Electrical Regulatory Authorities Council For more information on electrical equipment safety, go to www.erac.gov.au Safe Work Australia: Visit www.safeworkaustralia.gov.au to find the relevant work health and safety authority in your state or territory. Natural refrigerants www.environment.gov.au/atmosphere/ozone/publications/pubs/refrigerants-guide.pdf Fact sheet: The Automotive Industry and the ECP www.environment.gov.au/atmosphere/ozone/sgg/equivalentcarbonprice/publications/index.html 4 1 The cost recovery levy relates to the administration of the Act and is determined by multiplying the number of metric tonnes of the synthetic greenhouse gas by the prescribed levy rate ($165 per tonne). 2 This fact sheet contains information and extracts from ‘Natural Refrigerants – case studies’ produced by AIRAH in 2007 for the department. 3 Equipment that is suitable for the intended purpose as guaranteed by the retailer or manufacturer. 4 Refer to the departments automotive fact sheet located at: www.environment.gov.au/atmosphere/ozone/sgg/equivalentcarbonprice/publications/index.html 5 Prescribed equipment is equipment that is required to be approved prior to being offered for sale e.g. fridges and freezers. 5