"WALL STREET CORNER" BY WALLSTREETCORNER.COM, INC

advertisement

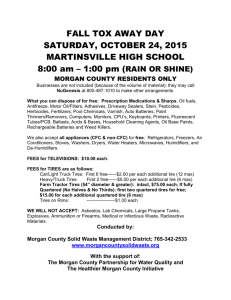

"WALL STREET CORNER" BY WALLSTREETCORNER.COM, INC. www.WallStreetCorner.com Integrated Technology Group Environmentally Safe Tire Recycling ESSENTIALS Business: Listed: Symbol: Shares Out: Approximate Float: Market Cap (at 6/8/2001): Waste Tire Recycling OTC BB ITGI 11,125,000 2.1 million shares $11.6 million Total Current Assets:* Total Assets:* Current Liabilities:* Long-Term Debt:* Shareholders' Equity:* Accumulated Deficit:* $1,177,497 $9,638,577 $4,181,937** $14,778 $5,346,512 ($10,741,858) Revenue (Yr. ended 12/31/2000): Net Loss (Yr. ended 12/31/2000): $8,932,702*** ($2,124,972)*** * As of 12/31/2000. The company's 10QSB dated 5/21/2001 contains the following statement: "The balance sheet does not reflect the inventory of tire chips created by the company since it began the process of converting tires to tire chips. The company owns 225,231 tons of tire chips." ** Includes $1,062,875 in accounts payable, $2,770,742 in current installments of long-term debt, & $348,320 in other current liabilities. *** See the "ADVANTAGES" section for additional comments. SUMMARY Many state & federal governmental agencies are requiring waste reduction at landfills. One of the targeted items to ban is scrap tires. Tires are a real problem in landfills -- they have a tendency to float up to the surface -- their construction traps landfill gas & makes them buoyant. In addition, it only takes 13 ordinary auto tires to occupy a cubic yard of landfill. These two problems are why most states now ban waste tires from landfills. There are other problems -- tires, no matter where they are dumped, collect rainwater, & the rubber stores heat, creating a perfect nesting environment for breeding disease carrying mosquitoes. Studies have shown that the incidence of encephalitis caused by mosquitoes is statistically higher in areas near scrap tire dumpsites. The dumpsites are also a fire hazard. In Winchester, VA, a pile of 9 million tires burned out of control for almost a year in 1984. One in Ontario with 14 million tires burned out of control for weeks in 1990, causing severe ground water contamination. There are between 750 million & 1 billion tires at dumpsites in the U.S., & about 280 million scrap tires are added every year. Where to put them is an enormous problem. ITGI is effectively dealing with this problem in TX & OK, & we predict that their technology & success in recycling scrap tires will serve as the model for expansion to other areas. HISTORY ITGI was formed in NV 5/8/98 as The Living Card Corporation. On 6/14/2000, it changed its name to Integrated Technology Group. Until then it was in the greeting card business. In 6/99, it completed its IPO of 2,000,000 shares at $0.10 (net proceeds about $168,000). On 6/16/2000, it began to trade on the OTC BB. In 7/2000, it acquired all the outstanding shares of Safe Tire Disposal Corp. It sold its Living Card assets to two major shareholders for cancellation of 5,900,000 restricted shares, reducing its outstanding to 2,100,000 shares. It issued 9,000,000 shares (80.89% after the close) to the owners of Safe Tire, in exchange for 100% of Safe Tire's shares. Safe Tire was then the only asset of the company, & operates as a 100% subsidiary. On 3/23/2001, ITGI announced it signed a letter of understanding with OTC Derivatives & Co. S.A., Geneva (OTCD) in which ITGI engaged OTCD to assist in its attempt to expand into the European Common Market. OTCD will provide expertise to present the company's solution to the worldwide problem of tire disposal, & help to locate potential financial partners in Europe. ITGI president Scott Holden says "We believe that now is the time to explore the possibilities in the European market. The European market has a greater awareness of the environmental problems posed by waste tires & we are now seeking guidance in our attempt to provide a solution." BUSINESS Safe Tire operates recycling plants in OK & TX. ITGI is paid to accept waste tires from tire retailers, stations, yards, & from clean-up jobs with governmental agencies, private individuals, & companies. It developed a process in which it uses shredders to reduce the tires to chips or pieces of rubber ranging from 1/2 inch to 2 inch in diameter. They can be used for energy recovery as "Tire Derived Fuel" (TDF), or for manufacturing & engineering applications, called "Tire Derived Product" (TDP). Its plants are environmentally friendly & produce virtually zero emissions. Safe Tire acquired the worldwide exclusive rights to a "Gasification" process, & ITGI applied for a strong patent on the process, which in now pending. The process is a closed-loop method of deriving petro-fuels from ground tire scraps by thermally degrading them to produce smaller, less complex molecules. The process recovers gas, oil, carbon, & steel. The carbon is refined to remove ash & other waste & is palletized or bagged & marketed to end-users. The gas, which has a heating value as high as 2375 Btu/cubic foot compared to natural gas that averages only 1000 Btu/cubic foot, goes through a condenser to produce oil. The oil has the consistency of a distillate fuel oil, & will be marketed to refineries or sold to fuel blenders who use it to produce other petroleum products. It can also be used as a fuel to run oil-fired boilers for the production of electricity. Extra gas is produced that does not condense into oil -- it is used to provide thermal energy to heat the tire chips, reducing operational energy costs. The process produces 500 pounds of carbon, 300 pounds of steel, & 2.5 barrels of oil per ton of used tires. The engineering is completed, ITGI has received authority from the state of OK to build the plant & operate the system. The site has been procured, & management anticipates being in operation in six to nine months. ITGI's formed a subsidiary for the gasification operation called "Recycled Energy." Several products are made from tire scraps. TDF can be used as an alternate fuel source in cement kilns & some industrial boilers & power plants. ITGI presently sells a significant amount of chips to such users. It has established a large demand of TDP for use as a leachate material in the construction of new landfill cells. The two-inch chips are used for such civil engineering applications as erosion control, filtration material, septic systems, & as road base material. Tire chips can be further reduced into crumb rubber, small rubber material that has no wire present (some is present in chips). Crumb rubber is used in the manufacture of rubberized asphalt, roofing materials, siding, automotive parts including hoses & body parts, electrical insulators, floor tiles, mats, poles, & other rubber based products. Crumb rubber is also useful as an end product in barns & stables, as a surface for racing tracks & horse arenas, & as a resilient, safer surface for playgrounds. On 9/13/2000, ITGI's Safe Tire subsidiary signed an agreement with Firestone's Arlington, TX distribution center to assist them in the proper disposal of the recycled tires they receive. ITGI actually began receiving tires from Firestone 8/28/2000. ITGI derives its revenues from two sources. The majority is generated from the tire shredding operations in TX & OK, with other revenue from the sales of tire chips. Two major markets so far developed are tire-derived fuel sales to cement kilns, & civil engineering sales for use in Subtitle D landfill cell construction. Since 1990, ITGI has collected about 26.3 million tires at it's Oklahoma facility & has marketed to end users 21.4 million tires (82%). In Texas, since it's start up in 1992, it collected 59.7 million tires & marketed 40.5 million tires to end users (68%). From 1992 to 1994 ITGI collected about 26.2 million tires that were held in inventory. In the summer of 1995, the TX government began to approve various markets in the State & as a result of those approvals ITGI, during the period from 1995 to 2000, collected 33.6 million tires & marketed to end users 39.8 million tires (118%). The inventories at the TX facilities have been reduced during that time period by 6.2 million tires. The remaining inventories at the OK & TX facilities will be used to support the gasification projects planned for those sites. On February 6, 2001, the Oklahoma Department of Environmental Quality approved an application for authorization to construct & operate a gasification system at ITGI's Choctaw, OK facility using recycled tires. ITGI is making similar applications in TX to construct & operate gasification systems using recycled tires at the Odessa, San Antonio, & Midlothian facilities. GOVERNMENTAL REGULATION ITGI derives its revenues principally from tire shredding operations in TX & OK. The laws of both TX & OK require the purchasers of new tires pay a tire disposal fee. Prior to the beginning of 2000, both TX & OK required that dealers charging this fee forward it to state agencies that would then pay various entities a portion of that fee to dispose of the tires. ITGI derived its revenues by converting the tires to chips, & received its revenues from the state as compensation for this conversion. Effective 9/97, the Waste Tire Program in TX ceased due to a sunset provision enacted in prior legislation. While dealers still charge a disposal fee, TX law now requires the dealers to arrange for the disposal of their tires. In TX, ITGI now markets its services directly to sellers of new tires. The change permits the company to receive a greater portion of the fee from dealers than the portion previously received from the state. Also during the period between 9/97 to 9/99, ITGI participated with the states' abandoned waste tire stockpile clean up program. It received the majority of the projects due to its ability to market all the tires collected from these dumps to a recycling end use. TX encountered a real problem after it cancelled its previous enforcement program & let scrap tires be handled in a free market. Scrap tire dumpsites proliferated. Efforts are underway in TX to enact legislation that ensures waste tires are directed towards recycling operations through an enforcement program. authorities to help this legislative effort. ITGI is cooperating with state COMPETITION The program in OK requires that entities receiving fees from the State gather tires from throughout the state. This places a significant financial burden on those gathering tires in OK to have the financial resources to conduct statewide operations, & acts as a barrier to entry by other competitors. While ITGI now generates its revenues by receiving essentially a tipping fee for disposing of tires, increasingly the issue for tire disposal is the complete recycling of tires into useful, environmentally benign products on an economic basis. Management believes that its gasification process is such a solution. Others have implemented what management believes to be partial solutions, particularly with the recycling of crumb rubber into mats. These recycling programs operate, however, in the opinion of management, on low margins & compete with a variety of existing products & materials while not disposing of tire chips containing wire. ITGI'S TEXAS PROPERTIES 1. Midlothian (south of Dallas/Ft.Worth); about 26 acres, with a processing plant of 11,000 square feet, a shop building of 1500 square feet & an office building of 1150 square feet. 2. San Antonio; about 37 acres, with a processing plant of 11,000 square feet & an office building of 1150 square feet. 3. Odessa; about 20 acres, with a processing plant of 11,000 square feet & an office building of 1150 square feet. 4. Cleveland (north of Houston); about 26 acres, with a collection & transfer facility of 11,000 square feet, a shop building of 800 square feet, & an office building of 1150 square feet. ITGI'S OKLAHOMA PROPERTY Choctaw; about 15 acres, with a processing plant of 10,000 square feet, a shop building of 9,200 square feet, & an office building of 2000 square feet. MANAGEMENT H. Scott Holden is president & CEO. He designed & oversaw construction of the OK & TX facilities & is singularly responsible for originating many of the design improvements. C. Sue Rushing is comptroller. She was the financial manager & comptroller of the Dornick Hills Golf & Country Club, Ardmore, OK. Her BS degree is in accounting from Southeastern Oklahoma State University. J. Daniel Ibarra is VP & general manager of the Southern Texas Division. He was general manager of sales & operations at Newell Industries (metal recycling). Jim A. Ellis is VP & general manager of the Northern Texas Division & Oklahoma. He was superintendent of plant operations at Uniroyal/Goodrich/Michelin's tire manufacturing plant in Ardmore, OK. Gary Crabtree is general manager of the Cleveland transfer station. He has over 15 years experience in the tire industry with extensive contacts at most of the large tire distribution chains. Harold H. Holden is advisor to the board & a consultant. He is chairman, president, & CEO of Holden Energy Corp., an independent oil & gas company established in 1977. It operates in the Mid-Continent area of the U.S. HEC has developed significant reserves & has an established record in the energy exploration field. It has 100% owned trucking, transporting, & supply company subsidiaries. ADVANTAGES o Can solve the tire disposal problem o Is paid to accept waste tires o Has four plants in TX & OK o Each plant processes 2000 tires per hour o Creates & sells products from the recycling process o One product is an alternate fuel source o Process is environmentally safe o Huge market -- U.S. generates 280 million scrap tires each year besides the 750 million to 1 billion tires now at dumpsites o Has patent pending for tire gasification technology that produces fuel oil Comments Re Recent Numbers: In Q1 ended 3/31/2001, ITGI incurred a loss of $711,996 compared to a loss of $892,742 in Q1 2000. In Q1 2001, ITGI issued 100,000 shares of common stock in connection with a capital-raising transaction for which the Company charged G&A expenses of $143,700. Excluding this charge, the loss would be $568,296, compared to a loss of $892,742 in Q1 2000, a reduction of $324,446. Again, if this charge is excluded, the decline in net loss would reflect an almost identical reduction in the Company's operating loss by $324,711, from $791,491 in the earlier period to $466,780 in fiscal 2001. The reduction of these losses is principally attributable to an increase in revenues of $184,063, from $1,736,784 to $1,920,847, & a decrease of $138,109 in operating expenses other than depreciation & amortization. The largest decline in operating expenses, excluding the charge related to the issuance of stock, was $86,323 & came in reduced G&A expenses. The increase in revenues is principally attributable to an increase in tire processing revenues. This increase reflects ITGI's additional marketing to tire retailers in TX. We like the environmental advantages of ITGI's technology. We see it emerging from its effective start-up phase after having acquired Safe Tire Disposal Corp. We predict that its gasification technology will generate a quantum leap for ITGI over the next two years. We feel it's a sleeper. LOCATION ITGI is located at 301 West Main, Suite 500, Ardmore, OK 73401. Call 580-226-0511, or fax 580-223-1798. DISCLAIMER: The special situation public companies covered in this section of this site pay an annual fee of US$5,000 to have their profiles lodged here. Information displayed by WallStreetCorner does not constitute an offer to buy, sell, or trade a security (stock). WallStreetCorner does not recommend that any person, institution, or other entity make any decisions or form any opinions, etc. based on the information on this site. All visitors to this site are urged to consult a qualified financial professional before taking any actions in regards to buying, selling, or trading securities (stocks). Companies covered in Conservative Speculator, a newsletter accessed from this site, or in Larry Oakley's editorial columns at this site (Opinion, Weekly Stock Pick, Mid-Week Comment, and Special Reports) do not pay for such editorial coverage. Conservative Speculator and Larry Oakley have never, do not now, nor ever will charge for editorial coverage.