38_SWP_MyHC Gel electrophoresis_CL

advertisement

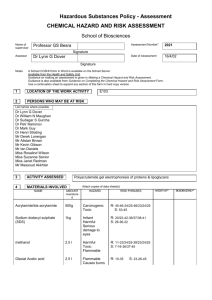

OHS026 Safe Work Procedure Faculty/Division Medicine Document number SOMS.CGM.SWP038 School/ Divisional Unit School of Medical Sciences Initial Issue date 30/6/09 Current version 1.0 Current Version Issue date 30/6/09 Next review date 30/6/12 The Writing Safe Work Procedures Guideline (OHS027) should be consulted to assist in the completion of this form. Safe Work Procedure Title and basic description Title: 12% High resolution SDS gel electrophoresis for Myosin Heavy Chains Description: Separating Myosin Heavy Chains isoforms by denaturing SDS polyacrylamide gel electrophoresis. Associated risk assessment title and location: 38_RA_MyHC gel electrophoresis_CL Describe the activity or process NOTE: Read all MSDS’s before starting experiment 1. Set up plates-rinse with dH20, 100% ethanol 2. Leave plates to dry Make up fresh Acrylamide-Bis solutions 30% Acrylamide (200:1) solution (i.e. 5.97g Acrylamide and 0.03g Bis make up to 20 mls) 30% Acrylamide (37.5:1) solution 3. Make up Ammonium Persulphate solution (APS) in eppendorf: (0.1g APS +1 ml dH20) 4. Make up resolving gel (follow table below), leave to set 1 hour 5. Make up lower buffer: 30.29g Tris + 142.6g Glycine and fill to 5L with stirrer 6. Make up upper buffer (and put in fridge): separate 1L from lower buffer, add below and put in fridge then add 20 ml 10% SDS to lower buffer, 10 ml 10% SDS to upper buffer + 0.3g DTT 7. Place cooler in tank (set to 5-6 degrees): should measure 10-12 degrees Make up Stacking Gel (follow table below) leave to set for 2 hours 12 % SDS-PAGE for separation of Myosin Heavy Chain Gels 12% Resolving gel 4% Stacking gel 30ml (2 gels) 20 ml (2gels) 100% glycerol 9 ml 6 ml 30% Acrylamide- Bis (200:1) 12 ml _ 30% Acrylamide-Bis (37.5:1) _ 2.6 ml 1.5 M Tris (pH8.8) 4 ml _ 0.5 M Tris (pH6.7) 2.8 ml 1M Glycine 3 ml _ 10% SDS 1.2 ml 0.8 ml 100mM EDTA (pH 7.0) 0.8 ml ___________________________________________________________________________________________________________ ___________ Page 1 of 3 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007 Distilled H2O 0.5 6.7 10% APS 0.3 ml 0.2 ml TEMED 4.5 ul 4.5 ul 8. For Normal run set limit voltage to 150V and limit current to 20 mA, for pulse (20s on/off) set limit current to 20 mA. 9. Stain gel in Coomassie Brillant Blue solution List all resources required including plant, chemicals, personal protective clothing and equipment, etc Equipment: Gel Pouring Apparatus Glass Plates and Spacer Bars Plastic Lane Combs Plastic Falcon Tubes Fume Hood Chemicals: 30% Acrylamide (200:1) solution 30% Acrylamide (37.5:1) solution 10% Ammonium persulphate (APS) N,N,N',N'-Tetramethylethylenediamine (TEMED) Resolving buffer (1.5M Tris.Cl pH 8.8) Stacking buffer (0.5M Tris.Cl pH 6.8) 10% (w/v) Sodium dodecyl sulfate (SDS) Tris and Glycine for Upper and Lower Buffers Coomassie Brilliant Blue Solution Personal Protective Equipment: Safety Goggles Lab Coat/Gown Face Mask List potential hazards and risk controls including specific precautions required Acrylamide – Toxic, carcinogen/mutagen, neurotoxin - may cause cancer and heritable genetic damage. Toxic in contact with skin and if swallowed. Danger of serious damage to health by prolonged exposure through inhalation, in contact with skin or if swallowed. May cause eye irritation and allergic skin reaction. Polymerization may occur from excessive heat or contamination. Wear safety goggles where splashing is possible. Wear enclosed shoes, nitrile gloves, and gown. Bis-acrylamide – Irritant. Irritating to eyes, respiratory system and skin. Harmful if swallowed, inhaled or absorbed. Toxic if ingested. Wear safety goggles where splashing is possible. Wear enclosed shoes, gloves and gown. TEMED - Corrosive. May flame on contact with heat or fire. Moderately toxic via oral route. Continuous exposure of low levels of vapour can cause a blurring of vision called "Blue Haze". Wear gloves, mask, goggles, and gown. Keep away from ignition sources. Ammonium Persulfate (APS) – Will cause irritation to eyes, which results in corneal injury, and to respiratory system. May cause irritation to skin. Wear safety goggles, nitrile rubber gloves, gown and enclosed shoes. SDS- Respiratory, skin and eye irritant. Harmful if swallowed, inhaled or absorbed through the skin. Severe eye irritant. Nuisance dust, but may also cause sensitization if inhaled. While working with SDS in solution, wear gloves, gown, and mask where risk of splashing is possible. SDS is kept in small (<100ml) volumes in the lab. ___________________________________________________________________________________________________________ ___________ Page 2 of 3 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007 Tris- Low toxicity- Skin, eye, and respiratory irritant. Decant in well ventilated areas. Wear gown and gloves when handling. Glycine- Low toxicity- eye irritant. Decant in well ventilated areas. Wear gown and gloves when handling. Glycerol- Low toxicity. Glycerol may present a hazard with direct eye contact or prolonged skin contact. Wear gloves and gown. Coomassie Brilliant Blue- Low toxicity. Wear gloves and gown, and goggles if measuring volumes greater than 1g. Power pack usage- All electrical items are hazardous. Because of the nature of this electrophoresis, there is a risk of liquid (ie buffers) contacting the power pack. List emergency shutdown instructions List clean up and waste disposal requirements Spillage of any solution used for the making of polyacrylamide gels should be cleaned up using the spill kit located in Rm 502. Paper towel used to mop up excess acrylamide solution should be disposed in the cytotoxic waste container Excess acrylamide solution should be polymerized with addition of APS and TEMED and disposed in the cytotoxic waste container. List legislation, standards and codes of practice used in the development of the SWP NSW OHS Act 2000 NSW OHS Regulation 2001 Safe Work Procedure Form (OHS026) Australia Dangerous Goods Code. AS/NZS 2243.2:2006. Safety in laboratories. Part 2: Chemical aspects Australian Standard AS2243.3-2002. Safety in laboratories. Part 3: Microbiological aspects and containment facilities. AS/NZS 2161.1:2000 Occupational Protective Gloves – Selection, Use and Maintenance AS/NZS 1336:1997 Recommended Practices for Occupational Eye Protection Supervisory approval, training, and review Supervisor: Edna Hardeman Signature: Plant custodian: Signature List competency required – qualifications, certificates, licencing, training - eg course or instruction: Training as per Training Needs Analysis, Induction to the Lab, Training in this SWP ___________________________________________________________________________________________________________ ___________ Page 3 of 3 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007

![Lab Safety Notes [8/31/2015]](http://s3.studylib.net/store/data/006888939_1-6bb01d0df93e4bd7262a0fecabf05a75-300x300.png)