Industrial Statistics and Operational Research Unit (ISO-RU)

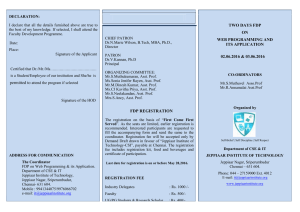

advertisement

Industrial Statistics/Operational Research Unit (ISO-RU) Service to Industries ISO-RU is able to provide a fast and efficient service to its clients. The Unit is completely self-financing and supports itself by providing consultancy and training. This self-supporting unit is dedicated to improve industrial processes via the uses of “Industrial Statistics”, “Quality Improvement Tools”, “Operational Excellence” , “Lean Manufacturing”, “Road Map to Six Sigma”, and “World Class Manufacturing (WCM)”, e.g. Problem Solving Methods Project Charter Gauge R&R Sigma Calculation Process Mapping/Base lining Statistical Methods Regression Analysis Analysis of Means/Variance Capability Studies Design of Experiments (DOE) Non-parametric Data Analysis Taguchi Analysis Response Surface Methodology (RSM) Control Plans Positrol Logs Poka-Yoke 5 S’s Productive Maintenance Procedure Documentation Control Charts Advanced SPC Failure Modes and Effects Analysis (FMEA) Measurement Systems Analysis (MSA) How to Contact ISO-RU: Departmental Office, Tel: (66)+2564-3001~9 Ext.3038, 3086 Fax: (66)+2564-3017 www.ie.engr.tu.ac.th Member Field Material Engineering Quality and Productivity Improvement Asst. Prof. Dr. Samerjit Tantaseraneewat Lean Manufacturing Quality Function Deployment (QFD) Industrial Statistics Design of Experiments (DOE) Asst. Prof. Dr. Pongchanun Luangpaiboon Production and Operational Management (POM) Response Surface Methodology (RSM) Evolutionary Operation (EVOP) Total Quality Management (TQM) Quality Economics Asst. Prof. Dr. Danupun Visuwan System Dynamics Simulation Engineering Management Quality Standard: ISO/TS/TL/Medical Devices/Food & Drug (FDA) Anuwat Homrossukon Safety Excellence in Manufacturing Measurement System Analysis (MSA) & Risk