P3_12_Lanzinger_Germany

advertisement

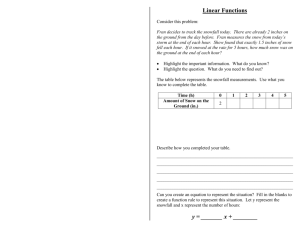

OPTIMIZED SNOW PLATES AND SNOW GRIDS FOR AUTOMATIC AND MANUAL SNOW DEPTH MEASUREMENTS Eckhard Lanzinger and Manfred Theel Deutscher Wetterdienst (DWD) Frahmredder 95 D-22393 Hamburg, Germany Tel.: +49(0)40 6690 2455 Fax: +49(0)40 6690 2499 e-mail: Eckhard.Lanzinger@dwd.de Abstract Manual measurements of snowfall depth are usually made by means of a graduated ruler. In order to measure only new snowfall the normal practice is to cover the old snow surface by a wooden or plastic board after the last measurement as a marker for the top layer. One drawback of these boards is an insufficient surface roughness resulting in reduced snow accumulation on the board compared to the surrounding in windy conditions. In this paper a grid board is proposed to replace the traditional board for undisturbed accumulation of snowfall and hence more accurate manual measurements. In the DWD network the traditional wooden snow plates are also used as a zero level plate for automatic measurements with ultrasonic snow depth gauges. Unfortunately the durability of such wooden plates is typically less than four years and the replacement of used up plates has become a cost factor. For this reason a durable, robust and cost effective solution has been developed and successfully tested. Glass fibre reinforced plastic is an appropriate material for both applications and allows to adequately define the design and surface roughness. Introduction As stated in the WMO Guide to Hydrological Practices [1] snowfall is the amount of fresh snow deposited over a limited period. To determine the amount of snowfall measurements are made of depth and water equivalent. In the ground network of Deutscher Wetterdienst (DWD) manual measurements of snow depth are regularly taken at about 2000 observation sites. Fresh snow on open ground is measured directly by means of a graduated ruler. In cases where there was already a snow cover on the ground before the snowfall started the Guide to Hydrological Practices recommends: “Special precautions should be taken so as not to measure any old snow. This can be done by sweeping a suitable patch clear beforehand or covering the top of the snow surface with a piece of suitable material (such as wood, with a slightly rough surface, painted white) and measuring the depth down to this.” In the network of DWD wooden snow boards are used for this purpose traditionally. The board is made of a 1 m² waterproof bonded plywood panel painted in white. The same snow plate is also in use as a zero level plate for ultrasonic snow depth gauges. -1- Meanwhile several disadvantages of these wooden boards became evident, namely high acquisition costs, low durability and bad adherence of snowfall in windy conditions due to insufficient surface roughness. Design of a snow grid As a result of a market survey glass fibre reinforced plastic (GRP) with an UV resistant coating was chosen as the appropriate and most cost effective material. In industrial and corrosive environments this material is widely used as a superior replacement for steel constructions. All kinds of GRP elements with a designated colour and surface roughness are produced for building units such as stairs on ships with non-skid surfaces. The surface roughness is accomplished by embedding grains of quartz of selectable diameter into the top coating. Among the standard GRP elements there are boards and gratings. We have chosen a grating with a mesh size of 12 mm x 12 mm and found that this structure will equally serve as a limit for the snowfall depth ruler. Figure 2: The snow grid is placed flush with an existing snow surface and the grid meshes fill with snow. Figure 1: GRP grating with a mesh size of 12 mm x 12 mm. The desired surface roughness is accomplished by quartz crystals that are embedded into the surface coating. In Figure 1 the selected roughness of the surface can be recognized. When placed flush with an existing snow surface (see Figure 2) the grid meshes will fill with snow. The rough quartz coated grating bars and the snow filled meshes provide a surface of almost naturally ideal adherence for fresh snowflakes. The position of the snow grid will be marked by a small GRP rod that is simply put into one of the meshes. A prototype has already been tested successfully at several manned stations in the DWD network. The observers confirmed that the snow grid is working well for the measurement and easier to handle. The user feedback has led to an optimized new design of the snow grid as depicted in Figure 3. The outer dimensions are 50 cm x 50 cm and the thickness of the grating is 12 mm resulting in a weight of about two kilograms. Four small legs will prevent the grid from freezing to the ground for easy removal. The feet are attached on two opposite sides of the square making the snow grids stackable to save storage room. The snow grid will be introduced in the network in winter 2010/2011. For automatic measurements with ultrasonic or laser snow depth gauges a closed surface is needed, i.e. the snow grid cannot be used for this measurement. The surface roughness of the GRP plates is very favourable for the accumulation of first snow on the plate. Several tests confirmed that it is not recommended to attach the snow plate directly to the bare ground. -2- Figure 3: Design of the new GRP snow grid for measuring snowfall depth. As can be seen in Figure 4 a small insulating air space is needed below the plate to give comparable results to a grass surface. Therefore the final version of the snow plate will basically be the same as the snow grid shown in Figure 3 but it will get with a closed plate as the top layer. Figure 4: Prototype test of two snow plates and one grid during a melting phase. The lower left plate is directly fixed at the ground, the upper right plate has a snow grid underneath to provide an air space between ground and plate. The lower right part is bare ground whereas the surrounding consists of short cut grass. The snow grid prototype can be seen in the upper left corner. The colour was chosen to be light grey instead of white for two reasons. First, the grass surface is not white either and second the grey surface gives a good optical contrast when first snow flakes settle on it. The latter is a very useful feature for detecting the first millimetres of snow with a laser snow depth gauge providing a valuable yes/no information for snow cover. Details will be given in our presentation [2] at TECO 2010. -3- Conclusions The snow grid is a newly designed tool for the manual measurement of snowfall depth. A prototype has been tested successfully at several manned stations in the DWD network. The snow grid will be introduced in the network in winter 2010/2011. The snow plate is designed for automatic measurements by means of ultrasonic or laser snow depth gauges. The grids and the plates can be produced from glass fibre reinforced plastic (GRP) which is a very cost effective and durable material. Colour and surface roughness of the material can be selected appropriately. The presented design of snow grids and snow plates is optimized with respect to undisturbed deposition of snow, comparable to that on natural snow or grass surfaces. References [1] WMO (1994): Guide to Hydrological Practices, 5th ed., WMO-No. 168. [2] Lanzinger, E. and Theel, M.: Improving reliability and sensitivity of a laser snow depth gauge. Presentation at TECO 2010, Helsinki, 30 August - 1 September 2010. -4-