TOC & Bottleneck Management: Sample Questions for Chapter 7

advertisement

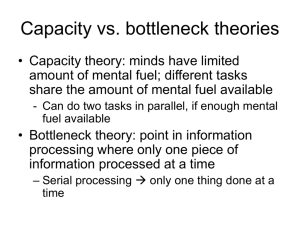

Sample questions for Chapter 7: 1. Work should be released into the system: a. when a customer order is received. b. when the first step in the process is idle. c. when a customer order is completed. d. when the bottlenecks need work. Answer: d 2. The time required to change a machine from making one product or service to the next is called: a. takt time. b. setup time. c. queue time. d. hold time. Answer: b 3. Which of the following statements regarding setups is TRUE? a. Unusually high setup times result in higher utilization. b. Processes are generating output throughout the entire setup process. c. A machine used in a line process would probably have fewer setups than a batch process. d. A TOC analyst would not be concerned with setup times on non-bottleneck machines. Answer: d 4. Which of the following is one of Dr. Eli Goldratt's rules of production scheduling for optimized production technology? a. Utilization and activation of a resource are not the same b. Do not allow bottlenecks to govern the flow of the line c. An hour lost at a bottleneck saves an hour for the entire system d. Balance the capacities, not the flows Answer:a 5. Which of the following is one of Dr. Eli Goldratt's rules of production scheduling for optimized production technology? a. Do not balance capacity, balance the flow b. If you lose an hour at a bottleneck it is better than making scrap c. Do not allow bottlenecks to govern the flow of the line d. An hour saved at a bottleneck operation is a mirage Answer:a 6. Which of the following is a “focusing step” of Dr. Eli Goldratt's theory of constraints? a. Reduce system constraints b. Reinforce system constraints c. Support system constraints d. Identify system constraints Answer: d 7. According to the theory of constraints which of the following is a financial measurement that can be used to measure the firm's ability to make money? a. Net profit b. Throughput c. Inventory d. Sales Answer: a 8. According to the theory of constraints which of the following can be a CCR? a. Factory layout b. Product design c. An employee d. Sales literature Answer: a 9. Which of the following is an approach to dealing with a bottleneck? a. Keep a buffer inventory in front of it to insure that it always has something to work on b. Don't worry about the bottleneck; it will take care of itself c. Move things to a faster bottleneck d. Pay an incentive bonus to workers on the bottleneck operation Answer: a 10. What is a word indicating a resource whose capacity is less than the demand placed on it? Answer: Bottleneck or Capacity Constrained Resource (CCR) 11. What is the rate at which money is generated by the system through sales called? Answer: Throughput 12. According to Dr. Goldratt, what is the goal of the firm? Answer: To make money 13. Explain why balanced capacity does not work all the time. 14. Define the concepts of bottleneck, non-bottleneck, and capacity constrained resource. 15. How can we optimize the bottleneck time? 16. What are the differences between TOC and JIT? 17. What are the major principles of TOC? 18. Define the concepts throughput, inventory, and operating expense.