OBJECTIVE & INTRODUCTION

advertisement

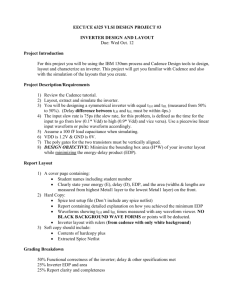

HW-5 DESIGN OF AN CMOS INVERTER USING MENTOR GRAPHICS (EE – 584) Submitted by LAKSHMAN KUMAR GOKAVARAPU Table of Contents Page 1. Objective and introduction 3 2. Schematic & symbol 4 3. Quicksim Simulation 5 4. Layout 6 5. LVS report 7 6. Parameter extraction 9 7. Accusim 9 8. Conclusion 10 2 OBJECTIVE & INTRODUCTION The objective of the given assignment is to design and test the working of an “INVERTER” using Mentor Graphics CAD tool. Following steps were adopted in designing and testing the circuit. 1. Schematic is designed using Design Architect. 2. Functional correctness of the schematic is tested using Quicksim. 3. Layout corresponding to the schematic is designed using IC workstation. 4. Verification of the layout is done using DRC rules and LVS check. 5. Parameter extraction is done using IC extract. 6. Functional Correctness of the layout is tested using Accusim. The inverter is realized using CMOS technology. When the input to the inverter is high the NMOS transistor is ON and the PMOS transistor is OFF (refer to figure 1).So the output of the inverter is low. When the input to the inverter is low the PMOS transistor is ON and the NMOS transistor is OFF and the output of the inverter is high. The truth table of the inverter is given in table-1. TRUTH TABLE IN OUT Logic 0 Logic 1 Logic 1 Logic 0 Table-1 3 SCHEMATIC & SYMBOL The transistor level schematic diagram of an inverter is shown in figure 1.In this schematic there is an NMOS and a PMOS transistor. The source of NMOS transistor is connected to the ground. The drain of the NMOS transistor is connected to the drain of PMOS transistor. The source of the PMOS transistor is connected to the power supply. The gates of both the transistors are connected together and the input is given to the gates of the transistors. The supply voltage is given 3 volts and the ground is assumed to be 0 volts. The W/L ratio of the PMOS transistor is twice that of NMOS transistor. figure.1 4 The symbol of the inverter is shown in figure 2. figure.2 QUICKSIM SIMULATION The quicksim result of the inverter is shown in fig3. The quicksim is run to verify the functional correctness of the schematic. In order to test for the functional correctness, all possible input combinations (0&1) are given and corresponding output for the given input is verified against the truth table. From figure.3 when the input to the inverter is logic 0, output is logic 1 and when the input is logic 1, the output is logic 0. figure.3 5 LAYOUT The layout corresponding to the schematic is designed in IC station tool of Mentor Graphics. This tool has the various layers of the design like “Active”,”Poly” etc in the form of toolbox. This toolbox could be “dragged and dropped” on the layout screen and then the size of the layers are modified using the various options like “Move”, “Copy” etc.The layout was designed using a pitch of 50. The “Pitch” is defined as the distance between the bottom layer of “ground” and upper layer of “VDD”.Figure.4 shows the mask layout of an inverter. The layout in figure.4 corresponds to schematic in figure.1. figure.4 6 “DRC (Design Rule Checker) rules” are the rules that define the spacing between various layers, which should be followed in designing a layout. The rules are given below: 2-Minimum width of poly. 2-Minimum width and length of contact 2-Minimum extension of poly beyond diff. 1.5-Minimum enclosure of contact by diff. 2-Minimum spacing between contact and poly. 3-Minimum poly-poly interspacing. After designing the layout, it is then subjected to design rule check (DRC).If the layout passes through the DRC, then it implies that the layout satisfies all the design rules. The layout shown in figure.4 successfully passed through the DRC. LVS REPORT The vital thing about the layout design is that it should match the circuit schematic. The layout is said to be correct only if the circuit and layout match in the number of “ports” and “instances”. This is done by LVS (Layout Versus Schematic) tool. The LVS tool requests the source (circuit schematic) path & name from the user and compares this with the layout. If they match then it generates a “SMILY FACE” indicating that the layout is correct. The LVS REPORT of this project is given in figure.5 and the table in figure.6 indicates the number of ports and instances. 7 figure.5 figure.6 8 PARAMETER EXTRACTION Parameter Extraction is done to extract and back annotate the “Lumped Parameters”. The values of Lumped Parameters including the “Intrinsic capacitances and resistances” could be obtained using this facility. ACCUSIM Accusim gives the analog simulation results of the layout.Accusim result of an inverter is shown in figure.7.In order to test for the functional correctness of the layout, varying voltage is applied to the input and the output voltage is observed. The layout has been tested for all possible input voltage swings. Since the input voltage is not digital voltage there is finite rise time and fall time for the inputs and also there would be rise time and fall time for the output. figure.7 9 From the figure.7 it is observed that when the input is 0 volts the output is 3 volts and when the input is 3 volts the output is 0 volts and hence the output follows the truth able. CONCLUSION Thus the CMOS Inverter was simulated using Mentor Graphics with a pitch of 50.The final layout obtained clearly matched the required objective of having a minimum total area. Also the rise time and fall time of input and output of the circuit schematic was found to be nearly equal to 1.7ns. 10